Content Menu

● Understanding Electrostatic Spray Guns

>> What Are Electrostatic Spray Guns?

>> Why Safety Is Paramount

● Preparing to Use the Electrostatic Spray Gun

>> Read and Follow Manufacturer's Instructions

>> Proper Training

>> Personal Protective Equipment (PPE)

● Safety Procedures During Operation

>> Grounding Requirements

>> Device Handling

>> Managing Overspray and Ventilation

>> Monitoring for Malfunctions

● Maintenance and Shutdown

>> Regular Cleaning

>> Power Off Safely

>> Handling Residual Charges

● Emergency Preparedness

>> Familiarize Yourself with Emergency Shutdown

>> Fire Prevention

● Frequently Asked Questions (FAQs)

>> 1. Why is grounding so important when using electrostatic spray guns?

>> 2. Can I wear any gloves while operating an electrostatic spray gun?

>> 3. What is the recommended safe distance between the spray gun nozzle and the surface?

>> 4. How often should electrostatic spray equipment be inspected?

>> 5. What PPE is essential for electrostatic spraying?

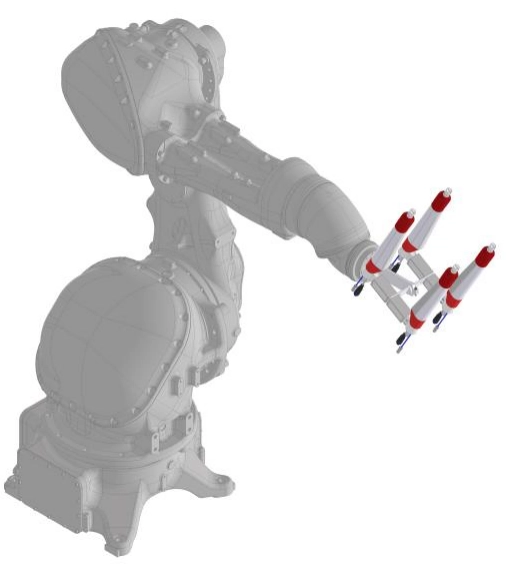

Operating automatic electrostatic spray guns safely is critical to ensure both personal safety and optimal functioning of the equipment. These specialized devices are widely used in industries such as automotive painting, manufacturing, and disinfecting processes due to their ability to deliver coatings and solutions efficiently and uniformly by charging spray particles. However, their use involves high voltage and sensitive electrical components, demanding strict adherence to safety protocols.

Understanding Electrostatic Spray Guns

What Are Electrostatic Spray Guns?

Electrostatic spray guns apply a high-voltage electrical charge to paint or other coating particles, which are then attracted to the oppositely charged target surface. This results in efficient coverage and reduced overspray.

Why Safety Is Paramount

Due to the high-voltage electricity involved, improper use can lead to shocks, sparks, or even fires. Ensuring proper grounding and handling practices protects users and the workplace environment.

Preparing to Use the Electrostatic Spray Gun

Read and Follow Manufacturer's Instructions

Before operating, carefully read the user manual specific to your model. Every gun has unique voltage settings, grounding requirements, and maintenance schedules.

Proper Training

Operators should receive comprehensive training covering:

- Equipment setup

- Operating procedures

- Safety measures

- Emergency responses

Personal Protective Equipment (PPE)

To safeguard against inhalation of particles, skin contact, or electrical hazards, operators should wear:

- Protective gloves (preferably leather or designed to avoid electric charge buildup)

- Safety goggles or face shields

- Respirators appropriate for the sprayed materials

- Leather-soled or electrostatic-dissipative shoes to prevent electric charge buildup

Safety Procedures During Operation

Grounding Requirements

A cornerstone of electrostatic spray safety is ensuring proper grounding:

- The operator should be grounded, often with grounding wrist straps.

- The object being sprayed must be connected to ground, typically via a grounded conveyor system.

- All metallic objects in the spraying area, including tables or tools, must be grounded to prevent charge accumulation.

Device Handling

- Operate the spray gun with bare hands; if gloves are worn, they should have openings at the palms to avoid trapping electric charge.

- Maintain a minimum distance of about 150mm between the gun's nozzle and the target to avoid sparks.

- Avoid overcharging by adhering to recommended voltage settings.

Managing Overspray and Ventilation

- Use shields or barriers to control overspray in confined spaces.

- Ensure adequate ventilation via exhaust fans or ducts to clear fumes and maintain air quality.

Monitoring for Malfunctions

- Regularly inspect the gun for wear, damage, or loose electrical connections.

- Ensure high-voltage cables and hoses are hung off the ground and free from damage.

- Do not soak electrical components in solvents.

Maintenance and Shutdown

Regular Cleaning

- Clean nozzles with recommended soft brushes; metal brushes can damage parts.

- Remove air caps and soak in solvent as appropriate.

Power Off Safely

- Always turn off the control box before cleaning or maintenance.

- Confirm zero voltage before nozzle cleaning to prevent sparks.

Handling Residual Charges

- After finishing work, discharge any residual static electricity safely before entering the painting area.

Emergency Preparedness

Familiarize Yourself with Emergency Shutdown

Know how to quickly and safely power down the system in case of electrical faults or fire risk.

Fire Prevention

- Keep paint booths clean and free of any flammable materials not in use.

- Avoid metal objects in paint booths that are not grounded.

Frequently Asked Questions (FAQs)

1. Why is grounding so important when using electrostatic spray guns?

Grounding prevents the buildup of static electricity that can cause sparks, shocks, or fires. It ensures the electrical charge flows safely to the earth.

2. Can I wear any gloves while operating an electrostatic spray gun?

No, gloves must allow grounding; ideally, gloves should have openings at the palms to prevent the user from becoming electrically charged.

3. What is the recommended safe distance between the spray gun nozzle and the surface?

Maintaining at least 150mm from the surface helps avoid sparking and ensures even coating.

4. How often should electrostatic spray equipment be inspected?

Regular inspections should be done daily or before every use to check for damage, wear, and electrical safety.

5. What PPE is essential for electrostatic spraying?

Operators must wear eye protection, respirators, grounding footwear, and protective gloves designed for electrostatic environments.

[1](https://totalfinishingsupplies.com/blogs/dispelling-myths-about-electrostatic-sprayers-affordable-and-safe-solutions/dispelling-myths-about-electrostatic-sprayers-affordable-and-safe-solutions)

[2](https://www.powderspraymachine.com/safety-management-of-electrostatic-spray-gun-spraying/)

[3](https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/electrostatic-spray-gun-frequently-asked-questions-faqs)

[4](https://www.powderspraymachine.com/safety-measures-for-electrostatic-spraying-machines-for-painting-equipment/)

[5](https://www.graco.com/gb/en/in-plant-manufacturing/solutions/articles/how-to-tackle-safety-issues-with-electrostatics-using-waterborne-materials.html)

[6](https://www.youtube.com/watch?v=h3zbxTAFKtY)

[7](https://www.sprayequipment.com/blog/dispelling-the-2-primary-myths-about-electrostatic-sprayers)

[8](https://archive.cdc.gov/www_cdc_gov/coronavirus/2019-ncov/php/eh-practitioners/sprayers.html)

[9](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/stay-grounded.html)

[10](https://www.coating-equipment.com/newspage/company10273.html)

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.