Content Menu

● Understanding the Basics

>> What are Reciprocators?

>> What are Fixed Gun Systems?

● Coverage Comparison

>> Efficiency of Coverage

>> Material Usage

● Advantages of Reciprocators

>> Enhanced Coating Quality

>> Flexibility and Adaptability

>> Automation and Labor Savings

● Disadvantages of Reciprocators

>> Initial Investment

>> Maintenance and Technical Expertise

● Advantages of Fixed Gun Systems

>> Lower Initial Costs

>> Simplicity of Operation

● Disadvantages of Fixed Gun Systems

>> Limited Coverage Capabilities

>> Inefficiency in Material Usage

● Applications of Each System

>> Industries Favoring Reciprocators

>> Industries Favoring Fixed Gun Systems

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a reciprocator over a fixed gun system?

>> 2. Are fixed gun systems more cost-effective?

>> 3. Can reciprocators handle complex shapes?

>> 4. What industries benefit most from reciprocators?

>> 5. Do fixed gun systems require less maintenance?

In the world of industrial coating, the choice between reciprocators and fixed gun systems is crucial for achieving optimal coverage and efficiency. This article delves into the differences between these two systems, exploring their advantages, disadvantages, and applications to help you make an informed decision.

Understanding the Basics

What are Reciprocators?

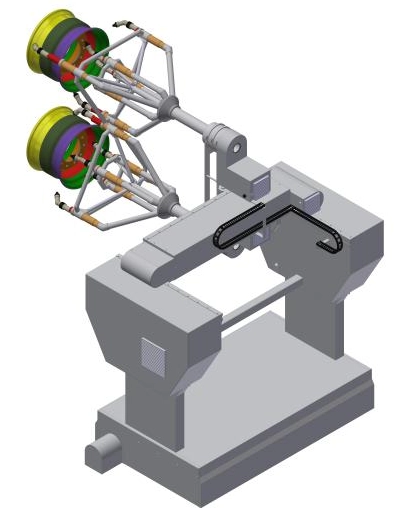

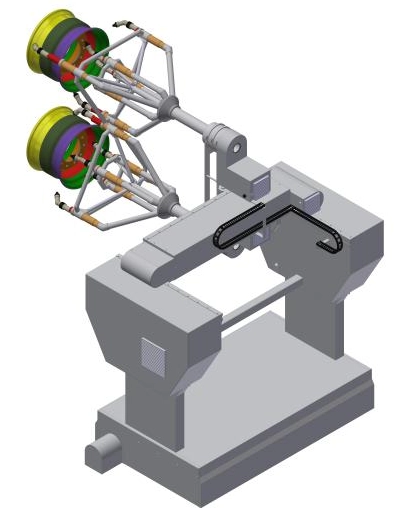

Reciprocators are automated systems designed to move spray guns in a controlled, repetitive motion. They can operate along one or more axes, allowing for precise application of coatings. This movement is typically linear and can be adjusted for speed and stroke length, making them suitable for various part sizes and shapes.

What are Fixed Gun Systems?

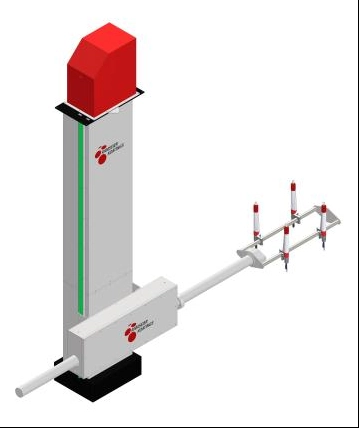

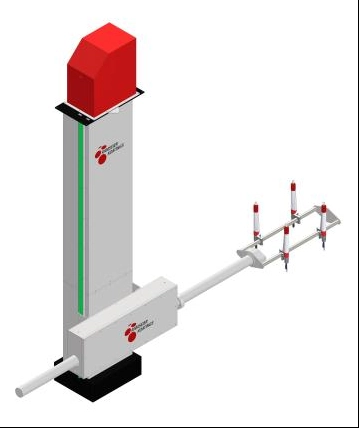

Fixed gun systems, on the other hand, are stationary setups where the spray guns remain in a fixed position while the parts move through the coating area. This system is simpler and often less expensive to implement, but it may not provide the same level of coverage and efficiency as reciprocators.

Coverage Comparison

Efficiency of Coverage

One of the primary factors to consider when comparing these systems is their efficiency in coating coverage. Reciprocators are known for their ability to provide uniform powder distribution. By moving the spray guns in programmed patterns, they minimize defects such as uneven thickness and runs, which are common in manual spraying or fixed systems.

In contrast, fixed gun systems can struggle with coverage, especially on complex geometries or when parts have irregular shapes. The stationary nature of fixed guns means that they may leave areas uncovered, particularly if the object has recesses or intricate designs.

Material Usage

Reciprocators also tend to be more efficient in terms of material usage. Because they can be programmed to optimize the spray pattern and adjust to the part's dimensions, they reduce waste and ensure that the coating is applied only where needed. Fixed systems, while simpler, may require more material to achieve the same coverage due to their less adaptable nature.

Advantages of Reciprocators

Enhanced Coating Quality

One of the standout benefits of reciprocators is their ability to enhance coating quality. The precise control over the spray pattern allows for a more consistent application, resulting in a superior finish. This is particularly important in industries where aesthetics and durability are critical, such as automotive and consumer goods.

Flexibility and Adaptability

Reciprocators offer greater flexibility compared to fixed systems. They can be programmed to handle various part sizes and shapes, making them ideal for manufacturers with diverse product lines. This adaptability can lead to increased productivity and reduced downtime, as the system can be quickly adjusted for different applications.

Automation and Labor Savings

By automating the coating process, reciprocators reduce the need for manual labor, which can lead to significant cost savings over time. Automation not only speeds up the coating process but also minimizes human error, further enhancing the quality of the finished product.

Disadvantages of Reciprocators

Initial Investment

While reciprocators offer numerous advantages, they typically require a higher initial investment compared to fixed gun systems. The complexity of the machinery and the need for programming and setup can make them more expensive upfront. However, many manufacturers find that the long-term savings in material and labor costs justify this initial expense.

Maintenance and Technical Expertise

Reciprocators may also require more maintenance and technical expertise to operate effectively. Regular calibration and adjustments are necessary to ensure optimal performance, which can be a drawback for companies without the necessary technical staff.

Advantages of Fixed Gun Systems

Lower Initial Costs

One of the most significant advantages of fixed gun systems is their lower initial cost. For companies just starting in the coating industry or those with limited budgets, fixed systems can provide a cost-effective solution for basic coating needs.

Simplicity of Operation

Fixed gun systems are generally simpler to operate and maintain. With fewer moving parts and less complexity, they can be easier for operators to manage, making them a suitable choice for smaller operations or those with less technical expertise.

Disadvantages of Fixed Gun Systems

Limited Coverage Capabilities

As mentioned earlier, fixed gun systems can struggle with coverage, particularly on complex parts. The inability to adjust the spray pattern dynamically can lead to inconsistent results, which may not meet the quality standards required in many industries.

Inefficiency in Material Usage

Fixed systems often result in higher material waste due to their less adaptable nature. This inefficiency can lead to increased costs over time, particularly for companies that require high-quality finishes and minimal waste.

Applications of Each System

Industries Favoring Reciprocators

Reciprocators are particularly favored in industries where precision and quality are paramount. This includes:

- Automotive Manufacturing: For coating car parts with high durability and aesthetic requirements.

- Electronics: Where precise coating is necessary for circuit boards and components.

- Furniture: For achieving a smooth, even finish on various surfaces.

Industries Favoring Fixed Gun Systems

Fixed gun systems may be more suitable for industries with less stringent coating requirements, such as:

- Construction: For coating large, flat surfaces where precision is less critical.

- Basic Manufacturing: Where cost is a primary concern and the quality requirements are not as high.

Conclusion

In conclusion, the choice between reciprocators and fixed gun systems largely depends on the specific needs of your operation. Reciprocators offer superior coverage, flexibility, and quality, making them ideal for industries that demand high standards. However, they come with a higher initial investment and require more technical expertise. Fixed gun systems, while simpler and more cost-effective, may not provide the same level of coverage and efficiency, particularly for complex parts.

Ultimately, understanding the strengths and weaknesses of each system will help you make an informed decision that aligns with your production goals and budget.

Frequently Asked Questions

1. What is the main advantage of using a reciprocator over a fixed gun system?

Reciprocators provide enhanced coating uniformity and quality due to their ability to move spray guns in controlled patterns, minimizing defects and material waste.

2. Are fixed gun systems more cost-effective?

Yes, fixed gun systems typically have lower initial costs and are simpler to operate, making them a more budget-friendly option for basic coating needs.

3. Can reciprocators handle complex shapes?

Yes, reciprocators are designed to adapt to various part sizes and shapes, making them suitable for complex geometries that fixed systems may struggle with.

4. What industries benefit most from reciprocators?

Industries such as automotive, electronics, and furniture manufacturing benefit from the precision and quality that reciprocators provide.

5. Do fixed gun systems require less maintenance?

Generally, yes. Fixed gun systems have fewer moving parts and are simpler to operate, which can lead to lower maintenance requirements compared to reciprocators.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.