Content Menu

● Understanding Electrostatic Spray Guns

>> What is an Electrostatic Spray Gun?

>> How Do They Work?

● Types of Powders Compatible with Electrostatic Spray Guns

>> 1. Epoxy Powders

>> 2. Polyester Powders

>> 3. Polyurethane Powders

>> 4. Fluoropolymer Powders

>> 5. Thermoplastic Powders

● Factors Influencing Powder Compatibility

>> Particle Size

>> Powder Fluidization

>> Environmental Conditions

● Best Practices for Using Manual Electrostatic Spray Guns

>> Proper Setup

>> Regular Maintenance

>> Training and Technique

● Conclusion

>> Frequently Asked Questions

Electrostatic spray guns have revolutionized the way coatings are applied in various industries, particularly in powder coating. These tools utilize electrostatic principles to ensure a more efficient and uniform application of powder coatings. However, not all powders are created equal, and understanding which powders work best with manual electrostatic spray guns is crucial for achieving optimal results. This article delves into the compatibility of different powders with manual electrostatic spray guns, exploring the best options available.

Understanding Electrostatic Spray Guns

What is an Electrostatic Spray Gun?

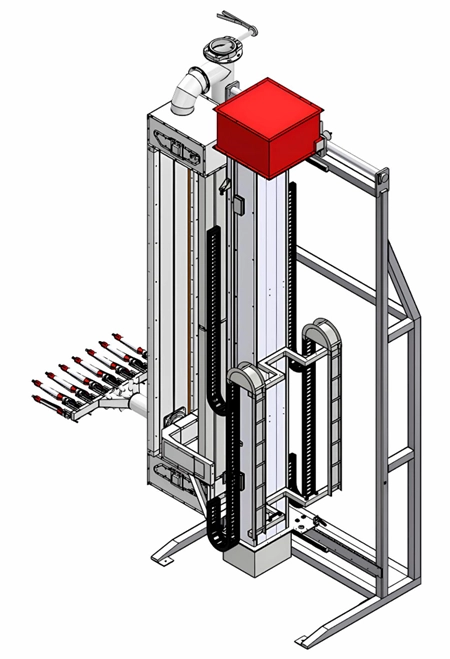

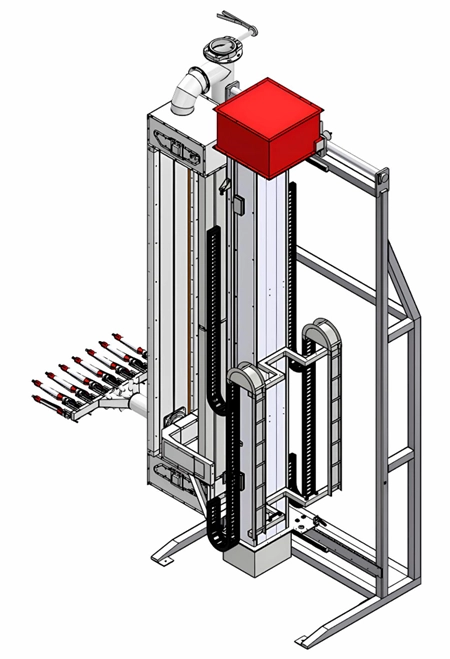

An electrostatic spray gun is a device that applies a charged powder coating to a surface. The gun charges the powder particles as they exit the nozzle, causing them to be attracted to the grounded object being coated. This process not only enhances the efficiency of powder application but also reduces overspray, leading to less waste and a more environmentally friendly process.

How Do They Work?

The operation of an electrostatic spray gun involves several key components:

- Power Supply: Provides the high voltage necessary to charge the powder particles.

- Hopper: Holds the powder and feeds it into the spray gun.

- Nozzle: Atomizes the powder and directs it towards the workpiece.

- Grounding: Ensures that the object being coated is properly grounded to attract the charged particles.

Types of Powders Compatible with Electrostatic Spray Guns

1. Epoxy Powders

Epoxy powders are known for their excellent adhesion and durability. They are commonly used in industrial applications due to their resistance to chemicals and corrosion. When using manual electrostatic spray guns, epoxy powders can provide a smooth finish and are ideal for metal surfaces.

2. Polyester Powders

Polyester powders are versatile and can be used in a variety of applications, including automotive and architectural coatings. They offer good weather resistance and color retention, making them suitable for outdoor applications. Manual electrostatic spray guns can effectively apply polyester powders, ensuring a uniform coating.

3. Polyurethane Powders

Polyurethane powders are known for their toughness and flexibility. They are often used in applications requiring a high level of abrasion resistance. These powders can be effectively applied using manual electrostatic spray guns, providing a durable finish that withstands wear and tear.

4. Fluoropolymer Powders

Fluoropolymer powders, such as PTFE, are used for their non-stick properties and resistance to high temperatures. These powders are ideal for applications in the food industry and other environments where cleanliness is paramount. Manual electrostatic spray guns can handle fluoropolymer powders, although special considerations may be needed for optimal application.

5. Thermoplastic Powders

Thermoplastic powders can be re-melted and re-formed, making them suitable for applications where flexibility is required. They are often used in automotive and appliance coatings. Manual electrostatic spray guns can effectively apply thermoplastic powders, ensuring a consistent finish.

Factors Influencing Powder Compatibility

Particle Size

The particle size of the powder can significantly affect its compatibility with electrostatic spray guns. Finer powders tend to charge more easily and can be applied more uniformly. However, they may also be more prone to clogging the gun. It is essential to choose powders with the appropriate particle size for the specific spray gun being used.

Powder Fluidization

Proper fluidization of the powder is crucial for consistent application. Powders that are difficult to fluidize may not perform well in electrostatic spray guns. It is important to select powders that are designed for use with electrostatic systems, as they are typically formulated to ensure optimal fluidization.

Environmental Conditions

Humidity and temperature can impact the performance of powder coatings. High humidity can cause powders to clump, while extreme temperatures can affect the curing process. It is essential to consider the environmental conditions when selecting powders for use with manual electrostatic spray guns.

Best Practices for Using Manual Electrostatic Spray Guns

Proper Setup

Ensuring that the spray gun is set up correctly is vital for achieving the best results. This includes adjusting the voltage, air pressure, and powder flow rate according to the manufacturer's specifications. A well-calibrated gun will provide a more uniform coating and reduce the risk of defects.

Regular Maintenance

Regular maintenance of the spray gun is essential for optimal performance. This includes cleaning the nozzle and other components to prevent clogging and ensuring that all parts are functioning correctly. A well-maintained gun will provide consistent results and extend the lifespan of the equipment.

Training and Technique

Proper training in the use of manual electrostatic spray guns can significantly impact the quality of the finish. Operators should be familiar with the specific techniques for applying different types of powders, including the appropriate distance from the workpiece and the speed of application.

Conclusion

Choosing the right powder for manual electrostatic spray guns is crucial for achieving high-quality finishes in various applications. Epoxy, polyester, polyurethane, fluoropolymer, and thermoplastic powders all offer unique benefits and can be effectively applied using these guns. By understanding the compatibility of different powders and following best practices, operators can enhance their coating processes and achieve superior results.

Frequently Asked Questions

1. What types of powders can be used with manual electrostatic spray guns?

- Common powders include epoxy, polyester, polyurethane, fluoropolymer, and thermoplastic powders.

2. How does particle size affect powder application?

- Finer powders charge more easily and provide a uniform application but may clog the gun.

3. What is the importance of powder fluidization?

- Proper fluidization ensures consistent application and prevents clumping of the powder.

4. How do environmental conditions impact powder coating?

- High humidity can cause clumping, while extreme temperatures can affect curing.

5. What maintenance is required for electrostatic spray guns?

- Regular cleaning of the nozzle and components, along with checking for proper function, is essential.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.