Content Menu

● How electrostatic spray works

● Benefits of manual electrostatic spray guns

● When a manual electrostatic spray gun makes sense

● Comparison with other coating methods

● Factors to consider before purchasing

● Setup considerations for efficacy

● Quality assurance and process control

● Common challenges and how to address them

● Case study: improving efficiency with a manual electrostatic approach

● Implementation roadmap

● FAQs

● Final thoughts

Choosing the right coating application tool can significantly impact product quality, process efficiency, and overall cost of ownership. A manual electrostatic spray gun offers a unique combination of portability, ease of use, and spray performance that can be attractive for various manufacturing environments. This article explores how manual electrostatic spray guns work, where they excel, common pitfalls, and how to determine if this technology aligns with your operation's goals.

How electrostatic spray works

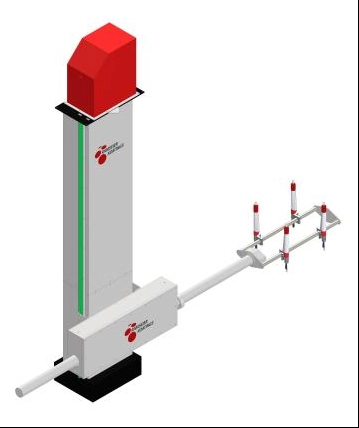

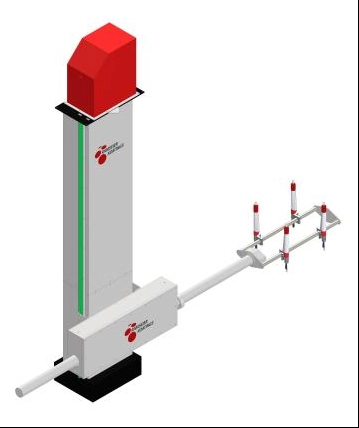

Electrostatic spray technology uses electrical charges to atomize and charge a coating as it exits the spray gun. The charged droplets are attracted to grounded or oppositely charged parts, resulting in improved transfer efficiency and reduced overspray. The coating forms a more uniform film as it adheres to complex geometries, recessed areas, and intricate contours where traditional spray methods may struggle.

Key principles include:

- Charge generation that imparts an electrical potential to the coating droplets.

- Electric field guidance that directs droplets toward the workpiece.

- Fluids and coatings designed for electrostatic compatibility to ensure stable charging and spray performance.

A manual device relies on operator input to control pattern shape, flow rate, and pressure while benefiting from the electrostatic field to maximize transfer efficiency. The result is less waste, reduced environmental impact, and often a smoother finish on challenging parts.

Benefits of manual electrostatic spray guns

- Higher transfer efficiency: More coating adheres to the target, less overspray, and less waste.

- Better edge and contour coverage: Charged droplets hug the surface, including recessed features and complex geometries.

- Improved finish quality: Fewer runs and sags due to even deposition and reduced dry spray.

- Lower solvent usage: Efficient deposition can reduce the amount of solvent needed for the same coating coverage.

- Portability and flexibility: A handheld tool is easy to move between stations or work cells without fixed automation.

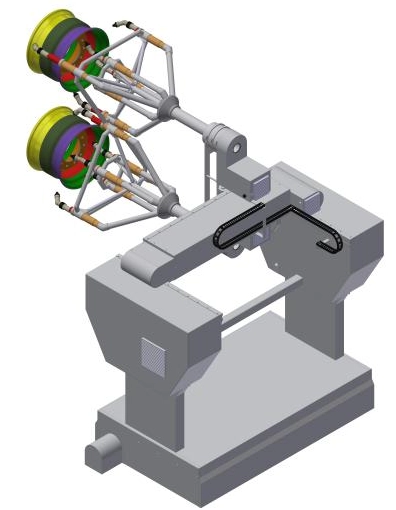

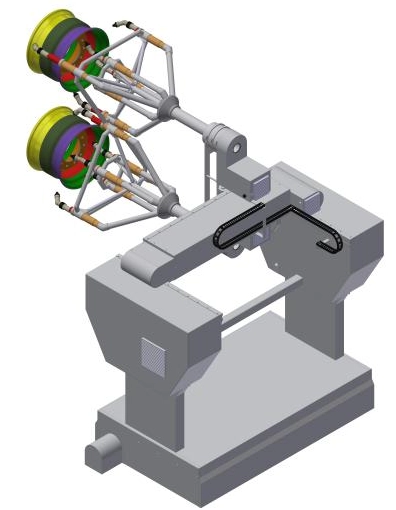

These advantages often guide manufacturers toward hybrid setups that combine manual electrostatic spray guns with simple fixtures or ergonomic enhancements to optimize throughput and consistency.

When a manual electrostatic spray gun makes sense

- Short run or prototype production: Quick setup and fast changeovers are valuable when volumes are too small to justify full automation.

- Complex geometries: Parts with hard-to-reach areas benefit from charged droplets that ensure even coverage.

- Batch or job shop environments: Varied workpieces and frequent product changeovers favor a flexible tool.

- Finishes requiring precise film build: When control over coating thickness and uniformity is critical, electrostatic charging helps achieve consistent results.

However, it is important to evaluate whether the added setup steps, operator training, and maintenance of a manual system align with your expected throughput and skill level.

Comparison with other coating methods

| Method | Key Advantage | Typical Use Case | Potential Drawbacks |

| Manual electrostatic spray | High transfer efficiency, good for complex geometries | Small to medium runs, job shops | Operator dependence, variable consistency |

| Conventional air spray | Simple, low initial cost | Large flat surfaces, straightforward geometries | Higher overspray, lower transfer efficiency |

| Automatic electrostatic spray | High consistency, high throughput | High-volume production, automation-heavy environments | Higher upfront cost, fixed layouts |

| Powder coating with electrostatics | Durable finishes, environmental benefits | Metal components, long lasting coatings | Requires baking ovens, different equipment |

This comparison highlights why a manual electrostatic gun can be a strategic choice for certain operations, especially where flexibility and finish quality are prioritized over maximum throughput.

Factors to consider before purchasing

- Coating compatibility: Ensure the coating's rheology, conductivity, and drying characteristics are compatible with electrostatic charging. Some materials may require reformulation or specific solvent systems.

- Performance requirements: Assess target film thickness, aiming precision, and the ability to maintain a consistent spray pattern across parts and fixtures.

- Operator training: A successful electrostatic process relies on operator skill, including grounding procedures, distance control, and spray technique.

- Grounding and safety: Proper grounding of the workpiece and the operator is essential to avoid stray charges. Safety considerations include handling of solvents and exposure control.

- Maintenance and consumables: Nozzles, wiring, and power supplies must be inspected regularly, and replacement parts should be readily available.

- Cost of ownership: Compare initial equipment costs with expected savings from reduced waste, faster cycle times, and improved finish quality.

Careful assessment of these factors helps determine whether the total cost of ownership and the expected gains justify adopting a manual electrostatic spray approach.

Setup considerations for efficacy

- Grounding strategy: Establish a robust grounding path for the part and any fixtures to minimize charge leakage and ensure consistent deposition.

- Distance and pattern control: Operator technique determines the stand-off distance and spray pattern. Training should emphasize maintaining a stable distance and even motion.

- Venues and ventilation: Adequate ventilation is necessary to manage overspray and solvent vapor, maintaining a safe and compliant workspace.

- Fixture design: Custom fixtures or simple racks can stabilize the part orientation, maintain consistent stand-off distances, and reduce operator fatigue.

- Pre- and post-treatment steps: Cleaning, surface preparation, and cure cycles influence adhesion, appearance, and overall coating performance.

An optimized setup combines thoughtful equipment selection with ergonomic workflow design to minimize variability and maximize yield.

Quality assurance and process control

- Calibration and testing: Regular checks of spray pattern, coating weight, and transfer efficiency help maintain consistency.

- Visual and functional inspection: Look for pinholes, runs, orange peel, or uneven thickness. Non-destructive testing may be used for critical applications.

- Statistical process control: Collect data on film thickness, cure times, and defect rates to identify trends and drive improvements.

- Documentation: Maintain records of settings, coatings, and maintenance for traceability and troubleshooting.

A disciplined QA approach ensures that the manual electrostatic spray process remains within specifications and continues to deliver a predictable finish.

Common challenges and how to address them

- Inconsistent transfer efficiency: Review grounding, nozzle alignment, and spray distance. Ensure coatings are properly thinned and within recommended viscosity ranges.

- Charging instability: Check power supply integrity, wiring connections, and electrode wear. Replace worn components and verify clean, dry surfaces.

- Overspray and drift: Tune the spray pattern, reduce air pressure if needed, and improve operator technique. Consider enclosure or local extraction if permissible.

- Operator fatigue: Improve ergonomics with lighter guns, balanced tooling, and adjustable stands or supports to reduce fatigue and improve control.

- Maintenance gaps: Implement a preventive maintenance schedule that covers cables, seals, and filters, and train operators to report abnormal performance.

Addressing these issues often yields immediate gains in consistency and waste reduction.

Case study: improving efficiency with a manual electrostatic approach

A mid-sized metal parts supplier faced high paint waste and inconsistent finishes on intricate components. By introducing a handheld electrostatic spray gun, paired with simple grounding fixtures and an under-hood ventilation system, the company achieved a noticeable reduction in material waste and a more uniform surface appearance across a range of parts. Training focused on consistent stand-off distances and smooth, continuous arm movements. Over several weeks, defect rates declined, and cycle times stabilized as operators grew comfortable with the equipment.

This example illustrates how targeted process improvements, even without full automation, can yield meaningful gains in quality and efficiency.

Implementation roadmap

1. Define objectives: Clarify coating goals, target thickness, and acceptable defect rates.

2. Assess suitability: Compare manual electrostatic spray with alternative methods for your specific parts and volumes.

3. Select equipment: Choose a gun with appropriate voltage range, nozzle size, and ergonomic design for your operators.

4. Plan grounding and fixtures: Design simple grounding methods and fixtures that stabilize parts during application.

5. Train staff: Provide hands-on coaching on technique, safety, and maintenance routines.

6. Pilot program: Run a controlled trial to gather data on transfer efficiency, finish quality, and waste.

7. Scale decision: Based on results, decide whether to expand usage, invest in automation, or adjust processes.

This structured approach helps ensure a smooth transition and minimizes disruption to production.

FAQs

- How does a manual electrostatic spray gun differ from a conventional spray gun?

- What coatings are best suited for electrostatic spraying?

- What are the safety considerations when using an electrostatic spray gun?

- How can I improve transfer efficiency in a manual electrostatic setup?

- What maintenance tasks are essential for consistent performance?

- Can electrostatic spray be used on non-metal surfaces?

- What is the typical lifespan of a spray gun nozzle in electrostatic applications?

- How does environmental temperature and humidity affect electrostatic spraying?

- Are there industry standards or certifications for electrostatic coating equipment?

- What training resources are available for operators new to electrostatic spraying?

Final thoughts

Manual electrostatic spray guns offer a compelling option for manufacturers seeking a balance between control, flexibility, and finish quality. They are particularly advantageous in environments with varied part geometries, smaller batch sizes, or where rapid changeovers are common. By paying careful attention to grounding, technique, and maintenance, facilities can realize reduced waste, improved coating performance, and a more efficient production workflow.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.