Content Menu

● Understanding Your Spray Gun

● Common Spray Gun Issues

>> 1. Inconsistent Spray Patterns

>>> Causes

>>> Solutions

>> 2. Paint Not Spraying

>>> Causes

>>> Solutions

>> 3. Leaking Paint

>>> Causes

>>> Solutions

>> 4. Spitting or Dripping

>>> Causes

>>> Solutions

>> 5. Orange Peel Finish

>>> Causes

>>> Solutions

● Maintenance Tips for Spray Guns

>> Cleaning After Use

>> Regular Inspections

>> Proper Storage

● Conclusion

>> Frequently Asked Questions

Spray guns are essential tools for achieving a smooth and even finish in various applications, from automotive painting to furniture refinishing. However, like any mechanical device, they can encounter issues that affect their performance. This article will guide you through common spray gun problems, their causes, and effective troubleshooting methods to ensure your spray gun operates optimally.

Understanding Your Spray Gun

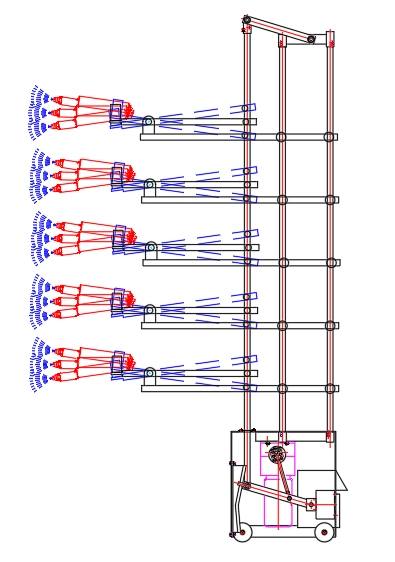

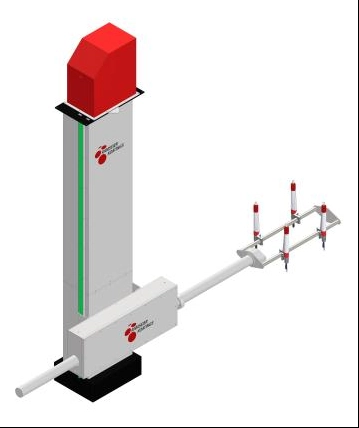

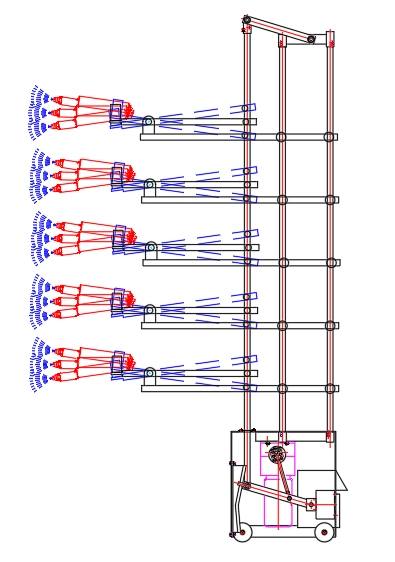

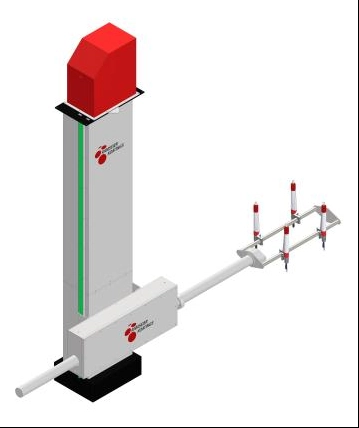

Before diving into troubleshooting, it's crucial to understand the basic components of a spray gun. Most spray guns consist of:

- Fluid Tip: Controls the amount of paint that is sprayed.

- Air Cap: Regulates the air pressure and pattern of the spray.

- Needle: Opens and closes the fluid passage.

- Trigger: Activates the spray mechanism.

- Fluid Cup: Holds the paint or coating material.

Familiarity with these components will help you diagnose issues more effectively.

Common Spray Gun Issues

1. Inconsistent Spray Patterns

Causes

- Clogged Nozzle: Dried paint or debris can block the nozzle, leading to uneven spray patterns.

- Incorrect Air Pressure: Too much or too little air pressure can affect the spray pattern.

- Improper Paint Consistency: Paint that is too thick or too thin can cause issues.

Solutions

- Clean the Nozzle: Disassemble the spray gun and clean the nozzle with a suitable solvent. Use a brush to remove any debris.

- Adjust Air Pressure: Check the air pressure settings on your compressor. Ensure they match the requirements for your specific spray gun.

- Check Paint Consistency: Use a viscosity cup to measure the thickness of your paint. Adjust by adding thinner if necessary.

2. Paint Not Spraying

Causes

- Blocked Air Vent: If the air vent is clogged, it can prevent paint from flowing.

- Empty Fluid Cup: Ensure there is enough paint in the cup.

- Faulty Needle or Trigger: A malfunctioning needle or trigger can prevent paint from being released.

Solutions

- Inspect the Air Vent: Clean any blockages in the air vent to allow proper airflow.

- Refill the Fluid Cup: Always check the fluid level before starting your project.

- Test the Needle and Trigger: Disassemble the gun and check for any damage or misalignment in the needle and trigger mechanism.

3. Leaking Paint

Causes

- Loose Connections: If the connections between the fluid cup and the gun are loose, paint can leak.

- Worn Seals: Over time, seals can wear out, leading to leaks.

- Damaged Nozzle: A cracked or damaged nozzle can also cause leaks.

Solutions

- Tighten Connections: Ensure all connections are secure and tight.

- Replace Worn Seals: Inspect seals for wear and replace them as necessary.

- Check the Nozzle: If the nozzle is damaged, replace it with a new one.

4. Spitting or Dripping

Causes

- Incorrect Fluid Pressure: Too low fluid pressure can cause spitting.

- Clogged Air Cap: A clogged air cap can disrupt the spray pattern and cause dripping.

- Improper Technique: Spraying too close to the surface can lead to drips.

Solutions

- Adjust Fluid Pressure: Increase the fluid pressure to ensure a steady flow.

- Clean the Air Cap: Remove and clean the air cap to ensure it is free of blockages.

- Modify Spraying Technique: Maintain a consistent distance from the surface while spraying.

5. Orange Peel Finish

Causes

- Too Thick Paint: Paint that is too thick can lead to an uneven finish.

- Incorrect Spray Technique: Spraying too quickly or at the wrong angle can cause texture issues.

- Low Air Pressure: Insufficient air pressure can prevent proper atomization of the paint.

Solutions

- Thin the Paint: Adjust the paint's viscosity by adding a suitable thinner.

- Practice Technique: Work on your spraying technique to ensure even coverage.

- Increase Air Pressure: Adjust the air pressure to the recommended settings for your spray gun.

Maintenance Tips for Spray Guns

Regular maintenance is key to preventing issues with your spray gun. Here are some essential maintenance tips:

Cleaning After Use

Always clean your spray gun immediately after use. This prevents paint from drying inside the gun, which can lead to clogs and other issues. Use a suitable solvent for the type of paint you used, and disassemble the gun for thorough cleaning.

Regular Inspections

Periodically inspect your spray gun for signs of wear or damage. Check the fluid tip, needle, and seals for any signs of deterioration. Replace any worn parts promptly to maintain optimal performance.

Proper Storage

Store your spray gun in a clean, dry place. Avoid leaving it in areas with extreme temperatures or humidity, as this can damage the components.

Conclusion

Troubleshooting spray gun issues can seem daunting, but with a systematic approach, you can quickly identify and resolve common problems. Regular maintenance and proper usage techniques will not only enhance the performance of your spray gun but also extend its lifespan. By following the guidelines outlined in this article, you can ensure that your spray gun remains a reliable tool for all your painting needs.

Frequently Asked Questions

1. What should I do if my spray gun is not spraying at all?

- Check for clogs in the air vent or nozzle, ensure the fluid cup is filled, and inspect the needle and trigger for proper function.

2. How can I prevent my spray gun from leaking?

- Regularly check and tighten all connections, replace worn seals, and inspect the nozzle for damage.

3. What causes an orange peel finish, and how can I fix it?

- An orange peel finish is often caused by thick paint or incorrect spraying technique. Thin the paint and practice your technique to achieve a smoother finish.

4. How often should I clean my spray gun?

- Clean your spray gun immediately after each use to prevent paint from drying and causing clogs.

5. What is the best way to store my spray gun?

- Store your spray gun in a clean, dry place, away from extreme temperatures and humidity.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.