Content Menu

● Understanding Electrostatic Spray Guns

>> What is an Electrostatic Spray Gun?

>> Benefits of Using Electrostatic Spray Guns

● Training Operators: Key Components

>> Equipment Familiarization

>> Techniques for Effective Use

>>> Proper Setup

>>> Application Techniques

>> Safety Protocols

● Maintenance Practices

>> Daily Maintenance

>> Periodic Maintenance

● Training Methods

>> Hands-On Training

>> Classroom Instruction

>> Evaluation and Certification

● Conclusion

>> Frequently Asked Questions

Content Menu

● Understanding Electrostatic Spray Guns

>> What is an Electrostatic Spray Gun?

>> Benefits of Using Electrostatic Spray Guns

● Training Operators: Key Components

>> Equipment Familiarization

>> Techniques for Effective Use

>>> Proper Setup

>>> Application Techniques

>> Safety Protocols

● Maintenance Practices

>> Daily Maintenance

>> Periodic Maintenance

● Training Methods

>> Hands-On Training

>> Classroom Instruction

>> Evaluation and Certification

● Conclusion

>> Frequently Asked Questions

Electrostatic spray guns are essential tools in various industries, particularly in painting and coating applications. They utilize electrostatic principles to improve transfer efficiency and reduce overspray, making them a preferred choice for many manufacturers. However, the effectiveness of these tools largely depends on the operators' training. This article will explore how to train operators for the effective use of manual electrostatic spray guns, covering essential techniques, safety measures, and maintenance practices.

Understanding Electrostatic Spray Guns

What is an Electrostatic Spray Gun?

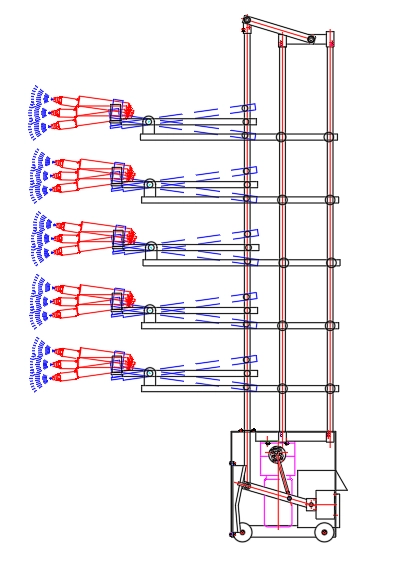

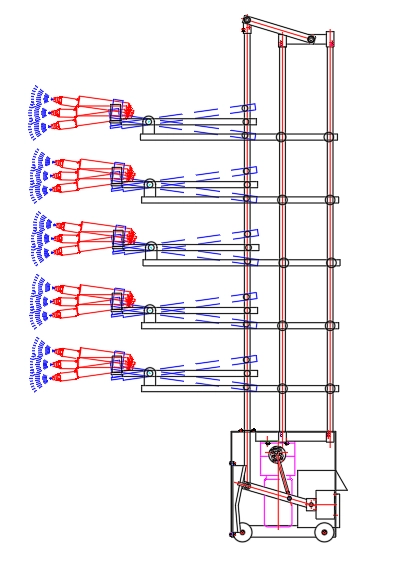

An electrostatic spray gun is a device that applies a charged coating material to a surface. The gun imparts a positive charge to the paint particles, which are then attracted to a grounded surface. This process enhances the coating's adherence and reduces waste, making it an efficient method for applying paints and coatings.

Benefits of Using Electrostatic Spray Guns

1. Improved Transfer Efficiency: The charged particles are attracted to the surface, resulting in less overspray and more efficient use of materials.

2. Enhanced Finish Quality: The even distribution of paint leads to a smoother finish.

3. Reduced Environmental Impact: Less overspray means less waste, contributing to a more sustainable operation.

Training Operators: Key Components

Training operators to use manual electrostatic spray guns effectively involves several key components, including understanding the equipment, mastering techniques, and adhering to safety protocols.

Equipment Familiarization

Before operators can effectively use electrostatic spray guns, they must be familiar with the equipment. This includes understanding the components of the spray gun, such as:

- High Voltage Generator: Provides the charge to the paint particles.

- Electrode: Creates the electric field that attracts the paint to the surface.

- Nozzle: Controls the spray pattern and flow of the coating material.

Techniques for Effective Use

Proper Setup

1. Grounding: Ensure that both the operator and the workpiece are properly grounded to prevent electrical hazards and ensure effective charging of the paint particles.

2. Adjusting Settings: Operators should learn how to adjust the voltage and air pressure settings based on the type of coating material being used.

Application Techniques

1. Distance and Angle: Operators should maintain a consistent distance (typically 6-12 inches) from the surface and keep the gun perpendicular to the workpiece for even coverage.

2. Spray Pattern: Use a zig-zag motion to cover the surface evenly, overlapping each pass by about 50% to avoid streaks and ensure complete coverage.

3. Trigger Control: Operators should practice triggering the gun at the end of each pass to minimize overspray and ensure a clean start and stop.

Safety Protocols

Safety is paramount when operating electrostatic spray guns. Operators should be trained in the following safety measures:

1. Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including gloves, masks, and goggles, to protect against inhalation of fumes and contact with chemicals.

2. Electrical Safety: Training should include understanding the risks associated with high voltage equipment and how to mitigate these risks through proper grounding and equipment handling.

3. Fire Safety: Since electrostatic spraying can create sparks, operators should be trained in fire safety protocols, including the use of fire extinguishers and emergency procedures.

Maintenance Practices

Regular maintenance of electrostatic spray guns is crucial for ensuring their longevity and performance. Operators should be trained in the following maintenance practices:

Daily Maintenance

1. Cleaning the Gun: After each use, operators should clean the gun to remove any residual paint. This includes flushing the system with the appropriate solvent and cleaning the nozzle and electrode.

2. Inspecting Components: Regularly check for wear and tear on components, such as hoses and nozzles, and replace them as necessary.

Periodic Maintenance

1. Calibration: Operators should periodically calibrate the spray gun to ensure it is functioning correctly and efficiently.

2. Professional Servicing: Schedule regular professional servicing to address any issues that may arise and to keep the equipment in optimal condition.

Training Methods

Hands-On Training

Hands-on training is essential for operators to gain practical experience with electrostatic spray guns. This can include:

- Demonstrations: Experienced trainers should demonstrate proper techniques and safety measures.

- Practice Sessions: Allow operators to practice under supervision, providing feedback and corrections as needed.

Classroom Instruction

Classroom instruction can complement hands-on training by providing theoretical knowledge about electrostatic principles, equipment operation, and safety protocols. This can include:

- Lectures: Covering the science behind electrostatics and the benefits of using electrostatic spray guns.

- Workshops: Interactive sessions where operators can ask questions and engage in discussions about best practices.

Evaluation and Certification

To ensure that operators are competent in using electrostatic spray guns, it is important to implement an evaluation process. This can include:

- Written Tests: Assessing knowledge of safety protocols, equipment operation, and maintenance practices.

- Practical Assessments: Evaluating operators' skills in a controlled environment to ensure they can apply what they have learned effectively.

Conclusion

Training operators for the effective use of manual electrostatic spray guns is a multifaceted process that involves familiarization with the equipment, mastering application techniques, adhering to safety protocols, and implementing regular maintenance practices. By investing in comprehensive training programs, companies can enhance the efficiency and safety of their operations, leading to improved product quality and reduced waste.

Frequently Asked Questions

1. What are the key benefits of using electrostatic spray guns?

- Electrostatic spray guns improve transfer efficiency, enhance finish quality, and reduce environmental impact due to less overspray.

2. How important is grounding when using electrostatic spray guns?

- Grounding is crucial to prevent electrical hazards and ensure effective charging of the paint particles.

3. What personal protective equipment should operators wear?

- Operators should wear gloves, masks, and goggles to protect against inhalation of fumes and contact with chemicals.

4. How often should electrostatic spray guns be cleaned?

- Spray guns should be cleaned after each use to remove residual paint and maintain performance.

5. What training methods are effective for teaching operators?

- A combination of hands-on training, classroom instruction, and evaluation through tests and practical assessments is effective for teaching operators.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.