Content Menu

● Understanding Automatic Electrostatic Spray Guns

>> What Is Electrostatic Spraying?

>> Components and Functions

● Setting Up the Spray Gun

>> Equipment Calibration

>> Safety Checks

● Proper Spray Techniques

>> Gun Handling and Movement

>> Containment Strategies

● Environmental and Safety Protocols

>> Personal Protective Equipment (PPE)

>> Fire and Electrical Safety

● Operator Performance Evaluation

>> Training Curriculum

>> Practical Testing

● Continuous Improvement and Troubleshooting

● Frequently Asked Questions

Training operators to use automatic electrostatic spray guns effectively is essential for maximizing coating quality, improving efficiency, and maintaining safety standards. This detailed guide covers key training components, techniques, and safety measures required for operators to excel in this specialized task.

Understanding Automatic Electrostatic Spray Guns

What Is Electrostatic Spraying?

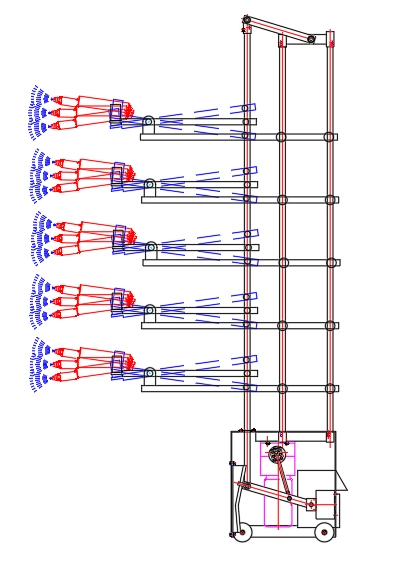

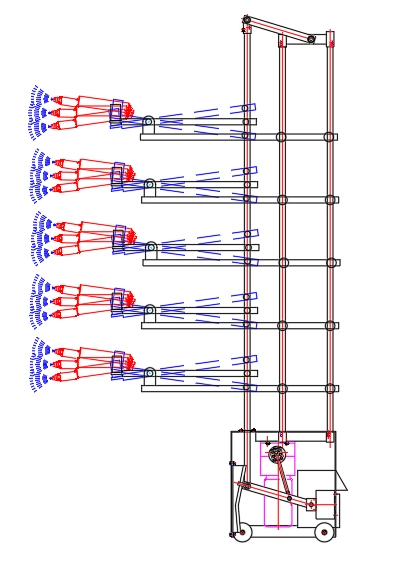

Electrostatic spray guns apply paint or coatings by electrically charging the particles, which are then attracted to a grounded target surface. This results in higher transfer efficiency and less overspray compared to conventional spray methods.

Components and Functions

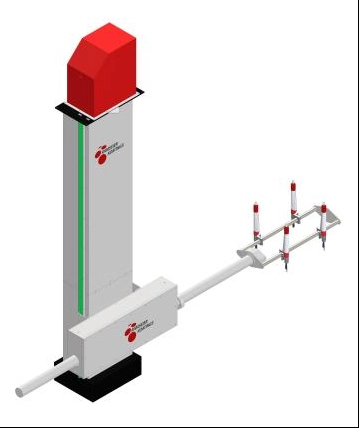

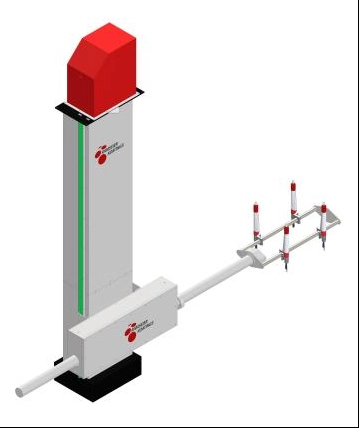

Operators must understand components such as the spray gun, power supply, fluid tip, and the control settings like voltage and pressure. Familiarity with the equipment helps in troubleshooting and optimization.

Setting Up the Spray Gun

Equipment Calibration

Proper calibration of pressure and voltage ensures optimal atomization and coating thickness. Operators must learn to set the lowest fluid pressure at which the coating is properly applied to minimize overspray.

Safety Checks

Training includes verifying that the electrostatic power cord is grounded and inspecting the gun and hoses for damage. Operators also need to ensure the part to be painted is properly grounded to attract the charged particles safely.

Proper Spray Techniques

Gun Handling and Movement

Operators should be trained to hold the gun perpendicular to the surface about 5-8 inches away, moving in smooth, overlapping strokes to ensure even coverage without pooling.

Containment Strategies

Use of containment flanges around molds or parts minimizes overspray loss. Operators must understand how to position and utilize these physical barriers effectively.

Environmental and Safety Protocols

Personal Protective Equipment (PPE)

Mandatory PPE includes eye protection, gloves, and respirators. Operators must be trained on proper PPE use and maintenance.

Fire and Electrical Safety

Electrostatic equipment can pose static discharge risks; training emphasizes grounding, avoiding static buildup, and emergency protocols.

Operator Performance Evaluation

Training Curriculum

A syllabus covering controlled spraying importance, spray gun setup, spraying techniques, and containment use.

Practical Testing

Operators demonstrate proficiency in equipment calibration, technique, safety practices, and environmental controls.

Continuous Improvement and Troubleshooting

Operators learn to identify common issues such as uneven coating, excessive overspray, or equipment malfunctions and apply corrective actions.

Frequently Asked Questions

1. What is the main advantage of electrostatic spraying?

It increases transfer efficiency, reducing coating waste and improving coverage.

2. How far should the spray gun be held from the surface?

Approximately 5 to 8 inches for consistent and even application.

3. Why is grounding important in electrostatic spraying?

Grounding prevents static discharge and ensures paint particles are attracted safely to the target.

4. What safety equipment is necessary during spraying?

Operators should wear eye protection, gloves, and respirators to protect against fumes and particles.

5. How can overspray be minimized?

By setting the lowest effective fluid pressure, using proper spray techniques, and containment flanges around the workpiece.

[1](https://acmanet.org/wp-content/uploads/2024/02/controlled-spray-training.pdf)

[2](https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/how-to-use-an-electrostatic-spray-gun)

[3](https://www.instructables.com/Spray-Gun-Beginners-Guide/)

[4](https://himalayas.app/career-guides/electrostatic-paint-operator)

[5](https://www.youtube.com/watch?v=h3zbxTAFKtY)

[6](https://www.youtube.com/watch?v=aMYT03LGe7M)

[7](https://www.youtube.com/watch?v=7K-gHNjOJkM)

[8](https://www.ramseierkoatings.com/how-to-maximize-transfer-efficiency-using-automatic-electrostatic-spray-guns.html)

[9](https://www.codinter.com/en/automatic-spray-guns-a-complete-guide/)

[10](https://www.graco.com/us/en/in-plant-manufacturing/support/education-center/liquid-finishing-spray-guns-applicators/electrostatic-spray-guns.html)

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.