Content Menu

● Understanding Powder Transfer Efficiency

>> What Is Powder Transfer Efficiency?

>> Importance of Transfer Efficiency

● Factors Affecting Powder Transfer Efficiency

>> Electrostatic Charge Levels

>> Powder Particle Size and Shape

>> Gun-to-Work Distance

>> Airflow and Spray Velocity

>> Surface Preparation and Grounding

● Techniques to Improve Powder Transfer Efficiency

>> Optimizing Electrostatic Parameters

>>> Adjusting Voltage and Current

>>> Enhancing Grounding

>> Selecting the Right Powder

>> Controlling Spray Gun Settings

>>> Spray Distance and Angle

>>> Air Pressure and Flow Rate

>> Environmental Controls

>>> Temperature and Humidity

>>> Ventilation Systems

● Advanced Strategies for Higher Efficiency

>> Use of Automated Powder Coating Systems

>> Conditioning the Substrate Surface

>> Employing Multiple Spray Guns

>> Powder Recovery and Reuse

● Troubleshooting Common Issues

>> Powder Bounce-Back

>> Back-Ionization Effects

>> Inconsistent Coating Thickness

● Recommended Maintenance Practices

● Frequently Asked Questions (FAQs)

Electrostatic spray guns have revolutionized powder coating by significantly improving coating quality and reducing waste. However, maximizing powder transfer efficiency remains a critical goal for many industries to enhance productivity and reduce costs. This comprehensive guide explores various techniques and best practices to increase powder transfer efficiency when using electrostatic spray guns.

Understanding Powder Transfer Efficiency

What Is Powder Transfer Efficiency?

Powder transfer efficiency refers to the percentage of powder particles that successfully adhere to the target surface compared to the amount of powder sprayed. High transfer efficiency means more powder lands on the workpiece, minimizing waste and overspray.

Importance of Transfer Efficiency

Improved powder transfer efficiency leads to:

- Reduced material waste and cost savings.

- Better coating uniformity and finish quality.

- Lower environmental impact due to less airborne powder.

- Enhanced worker safety by reducing powder inhalation risks.

Factors Affecting Powder Transfer Efficiency

Electrostatic Charge Levels

The effectiveness of electrostatic spray guns depends on the powder particles acquiring a strong charge, which helps them adhere better to the grounded substrate. Insufficient charge leads to poor attraction and low transfer efficiency.

Powder Particle Size and Shape

The physical characteristics of powder particles influence how they behave in the spray cloud. Uniform particle sizes and spherical shapes tend to produce better results.

Gun-to-Work Distance

The distance between the spray gun and the substrate affects how many powder particles reach the surface before settling or dispersing into the air.

Airflow and Spray Velocity

Proper airflow settings ensure that powder particles are sufficiently accelerated to the surface without causing excessive bounce-back or cloud formation.

Surface Preparation and Grounding

The substrate must be grounded effectively to attract the charged powder particles. Surface cleanliness and pre-treatment also affect adhesion.

Techniques to Improve Powder Transfer Efficiency

Optimizing Electrostatic Parameters

Adjusting Voltage and Current

Fine-tuning the electrostatic charge settings on the spray gun can significantly improve powder attraction. Higher voltages increase charge, but extremely high voltage can cause repulsion or back-ionization, reducing efficiency.

Enhancing Grounding

Ensure the workpiece is properly grounded. Use ground straps or grounding sprays if necessary to improve electrical conductivity and powder adherence.

Selecting the Right Powder

Different powders have unique flow and charging characteristics. Choose powders that are compatible with your spray system and provide consistent particle size and charge capacity.

Controlling Spray Gun Settings

Spray Distance and Angle

Maintain an optimal spray distance, typically between 6 and 12 inches, depending on gun specifications. Spray at a slight angle rather than perpendicular to reduce bounce-back.

Air Pressure and Flow Rate

Set the compressed air pressure and flow rate to create a well-atomized spray cloud with minimal overspray.

Environmental Controls

Temperature and Humidity

Maintain stable environmental conditions in the spraying area. High humidity can reduce static charge levels on powder particles, lowering transfer efficiency.

Ventilation Systems

Use proper ventilation and reclaim systems to minimize powder dispersion while ensuring smooth airflow.

Advanced Strategies for Higher Efficiency

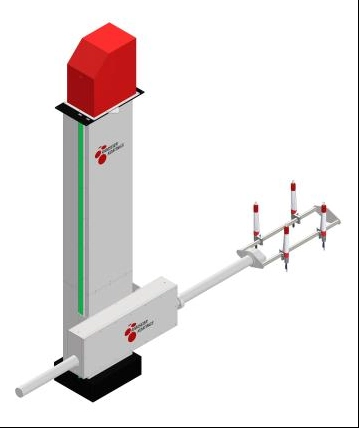

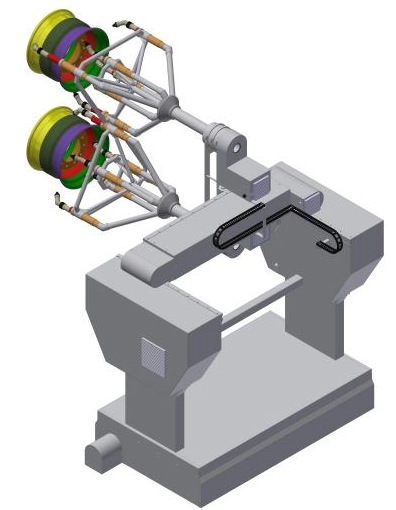

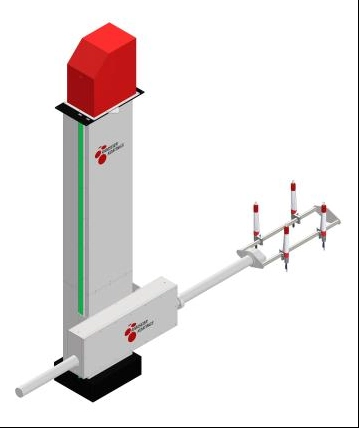

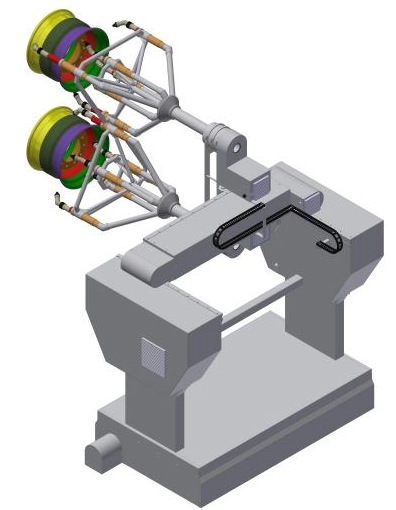

Use of Automated Powder Coating Systems

Robotic or automated spray systems ensure consistent gun movement and distance, which enhances coating uniformity and transfer efficiency.

Conditioning the Substrate Surface

Preheating the workpiece slightly can improve powder adhesion, especially with certain thermoplastic powders.

Employing Multiple Spray Guns

In complex parts or larger surfaces, using multiple synchronized spray guns can reduce overspray and improve efficiency by covering all areas evenly.

Powder Recovery and Reuse

Implement powder recovery booths or systems that collect overspray powder for reuse, improving material utilization and reducing waste.

Troubleshooting Common Issues

Powder Bounce-Back

Bounce-back occurs when powder particles hit the substrate but do not stick and instead disperse into the air. To reduce bounce-back, decrease spray distance, lower powder feed rate, or adjust gun angle.

Back-Ionization Effects

At very high voltages or close distances, the air near the substrate can ionize, creating a charge field that repels powder particles. Reducing voltage or adjusting spray distance can solve this.

Inconsistent Coating Thickness

Variations in powder feed or spray speed cause uneven coatings. Regular maintenance of equipment and careful operator training help maintain consistency.

Recommended Maintenance Practices

- Clean spray gun components regularly to prevent clogging.

- Inspect and replace worn nozzles or electrodes.

- Calibrate electrostatic controls and airflow systems periodically.

- Use high-quality powders and store them in dry, controlled environments.

Frequently Asked Questions (FAQs)

Q1: What is the ideal spray distance for electrostatic powder coating?

Typically, the best spray distance ranges from 6 to 12 inches, depending on the gun and application. Optimal distance reduces bounce-back and ensures good transfer efficiency.

Q2: How does humidity affect powder transfer efficiency?

High humidity reduces powder particle charge and adhesion, lowering efficiency. Maintaining lower humidity in the spray booth helps maintain proper charging.

Q3: Can all powders be used with electrostatic spray guns?

Not all powders are suitable. Powders must have proper charging and flow characteristics compatible with electrostatic equipment.

Q4: How often should electrostatic spray guns be maintained?

Regular maintenance after each use and monthly detailed inspections help ensure stable operation and efficiency.

Q5: What is back-ionization, and why does it matter?

Back-ionization is the ionization of air near the substrate caused by excessive voltage or closeness, repelling powder particles and reducing coating quality.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.