Content Menu

● Understanding Electrostatic Spray Technology

>> What is Electrostatic Spraying?

>> Benefits of Using Manual Electrostatic Spray Guns

● Selecting the Right Equipment

>> Choosing the Right Spray Gun

>> Essential Accessories

● Preparing for Application

>> Surface Preparation

>> Setting Up the Spray Gun

● Application Techniques

>> Proper Spraying Technique

>> Adjusting for Conditions

● Maintenance of the Spray Gun

>> Regular Cleaning

>> Routine Maintenance Checks

● Troubleshooting Common Issues

>> Inconsistent Coating

>> Poor Adhesion

● Conclusion

>> Frequently Asked Questions

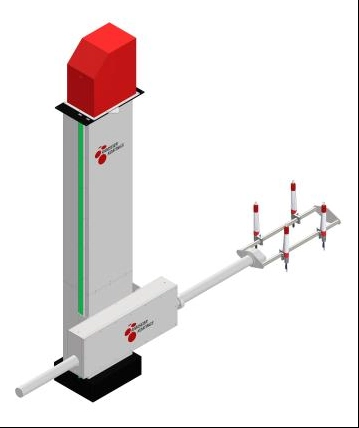

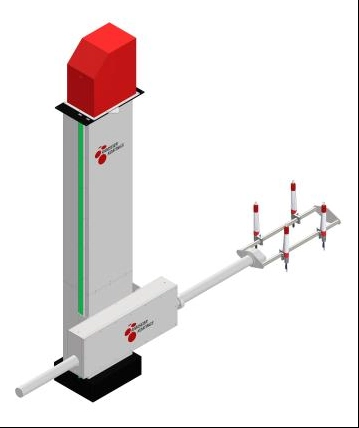

Electrostatic spray guns are essential tools in various industries, including automotive, furniture, and industrial coatings. They utilize electrostatic principles to enhance the quality of coatings applied to surfaces. This article will explore effective strategies to improve coating quality using manual electrostatic spray guns, covering everything from equipment selection to application techniques.

Understanding Electrostatic Spray Technology

What is Electrostatic Spraying?

Electrostatic spraying involves charging paint particles as they exit the spray gun, which are then attracted to a grounded surface. This process enhances transfer efficiency, reduces overspray, and ensures a more uniform coating. The electrostatic charge allows the paint to wrap around the object being coated, providing a more complete coverage compared to conventional spray methods.

Benefits of Using Manual Electrostatic Spray Guns

1. Improved Transfer Efficiency: Electrostatic guns can achieve transfer efficiencies of up to 90%, meaning less paint is wasted.

2. Reduced Overspray: The charged particles are attracted to the surface, minimizing the amount of paint that escapes into the air.

3. Uniform Coating: The electrostatic charge helps achieve a consistent layer of paint, which is crucial for aesthetic and protective purposes.

4. Cost-Effective: By reducing material waste, companies can save significantly on paint costs.

Selecting the Right Equipment

Choosing the Right Spray Gun

When selecting a manual electrostatic spray gun, consider the following factors:

- Type of Coating: Different guns are designed for specific types of coatings, such as water-based or solvent-based paints. Ensure compatibility with your materials.

- Nozzle Size: The nozzle size affects the spray pattern and coating thickness. A wider nozzle is suitable for thicker coatings, while a narrower one is better for finer finishes.

- Voltage Settings: Look for guns that allow you to adjust voltage settings, as this can impact the quality of the spray and the finish.

Essential Accessories

To maximize the performance of your electrostatic spray gun, consider investing in the following accessories:

- Pressure Pots: These help maintain a consistent flow of paint to the gun.

- Air Compressors: Essential for atomizing the paint effectively.

- Grounding Equipment: Proper grounding is crucial for the electrostatic process to work effectively.

Preparing for Application

Surface Preparation

Proper surface preparation is vital for achieving high-quality coatings. Follow these steps:

1. Clean the Surface: Remove any dust, grease, or contaminants that could affect adhesion.

2. Masking: Use masking tape and paper to protect areas that should not be coated.

3. Drying: Ensure the surface is completely dry before applying the coating.

Setting Up the Spray Gun

Before starting, ensure your spray gun is set up correctly:

- Check Connections: Ensure all hoses and connections are secure.

- Adjust Settings: Set the appropriate fluid and air pressure based on the manufacturer's recommendations.

- Test Spray: Conduct a test spray on a scrap piece to ensure the settings are correct.

Application Techniques

Proper Spraying Technique

To achieve the best results, follow these spraying techniques:

1. Distance from Surface: Maintain a distance of 6 to 12 inches from the surface. Too close can lead to drips, while too far can cause uneven coverage.

2. Steady Motion: Move the gun in a steady, sweeping motion to ensure even application. Avoid stopping in one spot to prevent buildup.

3. Overlap Passes: Overlap each pass by about 50% to ensure complete coverage without missing spots.

Adjusting for Conditions

Environmental conditions can affect coating quality. Consider the following:

- Humidity: High humidity can affect drying times and adhesion. Adjust your application technique accordingly.

- Temperature: Ensure the temperature is within the recommended range for the coating material to achieve optimal results.

Maintenance of the Spray Gun

Regular Cleaning

To maintain the performance of your electrostatic spray gun, regular cleaning is essential:

1. Flush After Use: After each use, flush the gun with a compatible solvent to prevent paint buildup.

2. Inspect for Clogs: Regularly check the nozzle and fluid delivery system for clogs that can affect spray performance.

3. Wipe Down: Clean the exterior of the gun to remove overspray and dust.

Routine Maintenance Checks

Implement a routine maintenance schedule to ensure your spray gun operates at peak performance:

- Disassemble for Deep Cleaning: Periodically disassemble the gun to clean hard-to-reach areas.

- Replace Worn Parts: Inspect seals and O-rings for wear and replace them as necessary to prevent leaks.

Troubleshooting Common Issues

Inconsistent Coating

If you notice inconsistent coating, consider the following potential causes:

- Improper Distance: Ensure you are maintaining the correct distance from the surface.

- Voltage Issues: Check the voltage settings on the gun and adjust as needed.

Poor Adhesion

If the coating is not adhering properly, it may be due to:

- Surface Contamination: Ensure the surface is clean and free of contaminants.

- Incorrect Coating Material: Verify that the coating material is compatible with the surface and the electrostatic process.

Conclusion

Improving coating quality using manual electrostatic spray guns involves a combination of proper equipment selection, meticulous preparation, effective application techniques, and diligent maintenance. By following the strategies outlined in this article, you can enhance the quality of your coatings, reduce waste, and achieve a professional finish.

Frequently Asked Questions

1. What is the ideal distance to hold the spray gun from the surface?

- The ideal distance is typically between 6 to 12 inches, depending on the specific application and material.

2. How often should I clean my electrostatic spray gun?

- It is recommended to clean the gun after each use and perform a deep cleaning periodically.

3. What should I do if I experience inconsistent spray patterns?

- Check for clogs in the nozzle, ensure proper voltage settings, and maintain the correct distance from the surface.

4. Can I use any type of paint with an electrostatic spray gun?

- No, it is essential to use coatings that are compatible with electrostatic application, such as specific water-based or solvent-based paints.

5. How can I improve transfer efficiency when using an electrostatic spray gun?

- Ensure proper grounding, maintain the correct distance from the surface, and adjust the voltage settings as needed.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.