Content Menu

● Introduction to Electrostatic Spray Guns and Reciprocators

● What Are Automatic Electrostatic Spray Guns?

>> Key Features of Electrostatic Spray Guns

● Understanding Reciprocators in Coating Systems

>> Definition and Function

>> How Reciprocators Work

● How Reciprocators Improve Efficiency

>> Enhancing Transfer Efficiency and Paint Utilization

>> Reducing Paint Waste and VOC Emissions

>> Improving Coating Consistency and Quality

● Technical Advances in Reciprocator-Electrostatic Gun Integration

>> Synchronization and Programmable Control

>> Paint Circulation Systems

>> Multiple Gun and Color Applications

● Case Studies of Efficiency Gains

>> Industrial Electric Fan Painting

>> Automotive and Metal Parts Coating

● Benefits Summary

● Frequently Asked Questions

>> 1. How do reciprocators affect paint consumption in electrostatic spraying?

>> 2. Can reciprocators be used for multi-color or multi-layer coatings?

>> 3. What industries benefit most from reciprocator and electrostatic gun systems?

>> 4. Does the use of reciprocators reduce volatile organic compound (VOC) emissions?

>> 5. How does paint circulation enhance reciprocator and electrostatic gun performance?

● Conclusion

Introduction to Electrostatic Spray Guns and Reciprocators

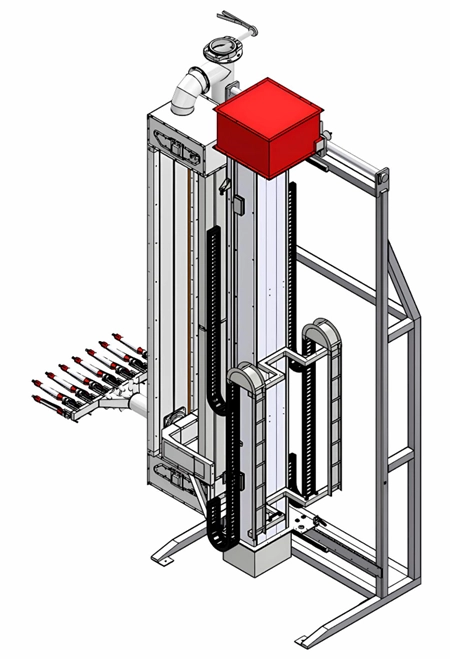

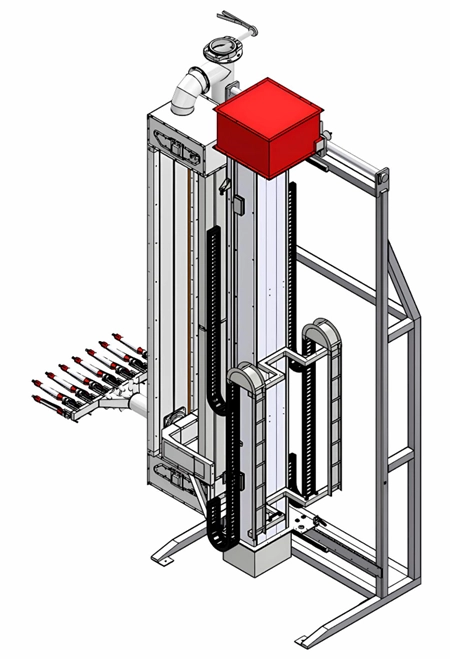

In modern industrial painting, achieving high efficiency and quality is critical to reducing costs, improving throughput, and producing durable finishes. Automatic electrostatic spray guns have revolutionized coating processes by imparting a charge to paint particles, attracting them to grounded workpieces, and significantly improving transfer efficiency. However, these spray guns reach their full potential when paired with reciprocators—mechanical devices that automate movement to optimize spray patterns. This article explores how reciprocators improve the efficiency of automatic electrostatic spray guns, detailing mechanism, benefits, and key factors impacting performance.

What Are Automatic Electrostatic Spray Guns?

Automatic electrostatic spray guns use an electrostatic charge to atomize paint particles and direct them efficiently. By charging the paint particles negatively and grounding the target object, the system ensures the paint adheres evenly and with minimal overspray. This process reduces paint waste and volatile organic compound emissions while improving finish quality and uniformity.

Key Features of Electrostatic Spray Guns

- High transfer efficiency due to charged paint particles

- Even coating with a superior finish quality

- Reduced paint consumption and waste

- Environmentally friendly with lower VOC emissions

- Compatibility with automated systems such as robots and reciprocators

Understanding Reciprocators in Coating Systems

Definition and Function

A reciprocator is a mechanical system that moves the spray gun in a controlled back-and-forth or up-and-down motion over a fixed path. This precise movement replaces manual spray gun operation, allowing for a consistent and repeatable spray application on large or irregular surfaces.

How Reciprocators Work

Reciprocators are programmed to move the spray gun with perfect timing and stroke length tailored to the part size and shape. This motion ensures the spray gun covers every area uniformly, preventing over- or under-coating segments of the surface.

- Controlled speed adjusts paint thickness

- Programmable stroke lengths match part dimensions

- Synchronization with part detection optimizes paint application timing

How Reciprocators Improve Efficiency

Enhancing Transfer Efficiency and Paint Utilization

By automating the spray gun's motion, reciprocators maintain the optimum distance and speed for transferring paint particles effectively. This minimizes the loss of paint that occurs during manual spraying due to inconsistent hand movements.

- More precise control reduces overspray

- Paint is atomized and electrically charged consistently across the entire surface

- Enhanced wraparound effect for complex shapes, resulting in better coverage and fewer coats needed

Reducing Paint Waste and VOC Emissions

Precise and repeatable reciprocator motion decreases paint waste by limiting the painted area strictly to the workpiece. The electrostatic effect further attracts paint particles to the surface, reducing airborne particles.

- Painting only when parts are present conserves materials

- Decreases the amount of paint settling on spray booth filters and surroundings

- Lowers emissions of volatile organic compounds, benefiting workplace health and environment

Improving Coating Consistency and Quality

Reciprocators eliminate human error, providing a uniform film thickness essential for both aesthetic appeal and product durability. The consistent motion helps build an even coating layer, reducing the need for corrective recoats.

- Consistency aids in corrosion protection and durability

- Ensures compliance with strict industry film thickness standards

- Produces a smoother, professional finish free of runs, drips, or thin spots

Technical Advances in Reciprocator-Electrostatic Gun Integration

Synchronization and Programmable Control

Modern systems integrate sensors and programmable logic controllers (PLCs) to synchronize reciprocator motion with paint flow and electrostatic charging. This automation optimizes spray timing, paint output, and gun positioning.

Paint Circulation Systems

To maintain optimum paint viscosity and prevent clogging during the reciprocator stroke, paint circulation systems keep paint chemistry consistent. These systems circulate paint continuously, avoiding blockages and ensuring smooth spray patterns.

Multiple Gun and Color Applications

Reciprocators can be fitted with multiple electrostatic spray guns, each delivering different colors or coatings. Independent control allows for complex multi-layer coating processes in a single pass.

Case Studies of Efficiency Gains

Industrial Electric Fan Painting

Using an automated reciprocator system with electrostatic spray guns has resulted in improved finish quality, reduced paint consumption, and enhanced durability for electric fan blades. The precise motion helped ensure even coating thickness across complex blade surfaces and minimized paint overspray.

Automotive and Metal Parts Coating

Reciprocators paired with electrostatic guns improve coating quality and cut paint costs by up to 40% compared to manual spraying. The improved wraparound effect of the spray guns with reciprocator movement provides better coverage of intricate parts, extending product life and reducing rework.

Benefits Summary

- Increased paint transfer efficiency and cost savings

- Significant reduction of paint waste and VOC emissions

- Superior coating uniformity and surface finish quality

- Automation reduces labor costs and speeds up production

- Flexibility for multi-gun and multi-color operations

Frequently Asked Questions

1. How do reciprocators affect paint consumption in electrostatic spraying?

Reciprocators optimize the spray gun's motion to deposit paint evenly and only when parts are present, reducing overspray and paint waste, thus lowering overall paint consumption.

2. Can reciprocators be used for multi-color or multi-layer coatings?

Yes, reciprocators can be equipped with multiple spray guns for different colors or coating layers with precise control over each gun's operation.

3. What industries benefit most from reciprocator and electrostatic gun systems?

Industries such as automotive, electronics, appliances, and metal fabrication benefit by achieving consistent finishes, reducing costs, and improving productivity.

4. Does the use of reciprocators reduce volatile organic compound (VOC) emissions?

Yes, by improving transfer efficiency and reducing overspray, reciprocators help minimize VOC emissions making the process more environmentally friendly.

5. How does paint circulation enhance reciprocator and electrostatic gun performance?

Paint circulation maintains consistent paint viscosity and flow, preventing clogging and ensuring smooth, uniform spray application throughout reciprocator operation.

Conclusion

Reciprocators significantly enhance the efficiency of automatic electrostatic spray guns by automating the precise motion required for optimal paint transfer and coverage. This synergy reduces paint waste, improves coating quality, cuts emissions, and accelerates production. The integration of advanced control systems, paint circulation, and multi-gun setups further expands the benefits across various industries. Employing reciprocators in electrostatic spray systems is a key innovation pushing industrial coating processes toward higher performance and sustainability.

[1](https://www.sames.com/usa/en/solutions-1-color-and-several-guns-on-reciprocator.html)

[2](https://bullows.com/uncategorized/bullows-auto-reciprocator-based-system-a-detailed-look-into-electric-fan-painting/)

[3](https://www.graco.com/gb/en/products/emea-manufacturing/efficiencies/electrostatic-painting-case-study-piston-upgraded-performance-and-product-quality.html)

[4](https://www.graco.com/us/en/in-plant-manufacturing/products/liquid-coating/spray-booth/spray-guns-applicators/electrostatic-paint-spray-guns.html)

[5](https://www.sunac.co.jp/en/products/eab500/)

[6](https://www.ramseierkoatings.com/how-reciprocators-reduce-powder-waste-and-increase-transfer-efficiency.html)

[7](https://www.ramseierkoatings.com/how-to-choose-the-right-reciprocator-for-your-coating-system.html)

[8](https://www.codinter.com/en/electrostatic-painting-main-applications/)

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.