Content Menu

● Understanding Powder Coating Automation

>> What Is Powder Coating?

>> Importance of Automation in Powder Coating

● What Are Reciprocators?

>> Basic Working Principle

>> Components of a Reciprocator System

● How Reciprocators Improve Powder Coating Automation

>> Uniform Coating Thickness

>> Enhanced Production Speed

>> Integration with Robotic Systems

>> Reduced Overspray and Waste

● Types of Reciprocators Used in Powder Coating

>> Pneumatic Reciprocators

>> Electric Reciprocators

>> Hydraulic Reciprocators

● Key Features to Look for in Powder Coating Reciprocators

>> Adjustable Stroke Length and Speed

>> Durable Construction

>> Smooth Motion Control

>> Easy Integration

● Practical Applications of Reciprocators in Powder Coating

>> Automotive Industry

>> Appliances and Electronics

>> Construction and Architecture

>> Custom Coating Lines

● Installation and Maintenance of Reciprocators

>> Installation Best Practices

>> Routine Maintenance Tips

● Challenges and Solutions When Using Reciprocators

>> Challenge: Limited Axis Movement

>> Challenge: Wear and Tear

>> Challenge: Syncing with Spray Guns

● Future Trends in Reciprocators for Powder Coating Automation

>> Smart Sensors and Feedback

>> Advanced Motion Control Algorithms

>> Modular and Scalable Designs

● Frequently Asked Questions About Reciprocators in Powder Coating

Powder coating is a widely used finishing process that offers superior durability, environmental benefits, and aesthetic appeal compared to traditional liquid paint applications. As industries continuously push towards higher efficiency and automation, reciprocators have emerged as vital components that significantly enhance the powder coating process. This article explores how reciprocators enhance automation in powder coating, explaining their role, benefits, types, and practical applications.

Understanding Powder Coating Automation

Automation in powder coating aims to streamline the coating process, reduce human error, improve finish quality, and increase throughput. It involves replacing or augmenting manual tasks with machines and controls, facilitating consistent results and efficient resource use.

What Is Powder Coating?

Powder coating is the application of a dry powdered paint on a metal or other conductive surface. Unlike liquid paints, the powder is electrostatically charged and sprayed onto the surface, adhering to it until it is cured under heat to form a hard, durable finish.

Importance of Automation in Powder Coating

Automation reduces manual labor, increases task precision, and speeds up the production line. It also minimizes waste and emissions, which is vital for regulatory compliance and sustainability.

What Are Reciprocators?

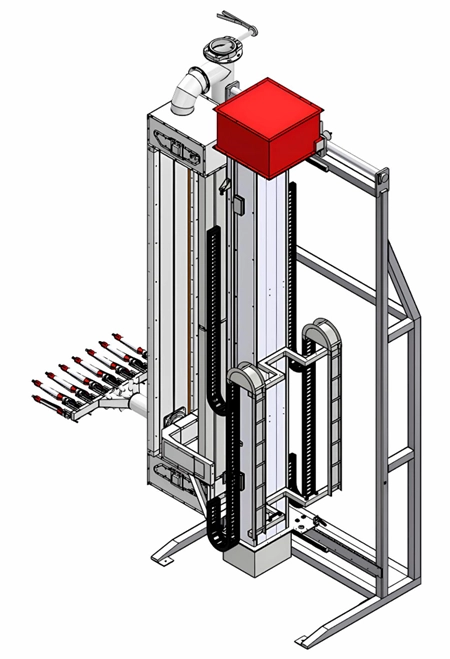

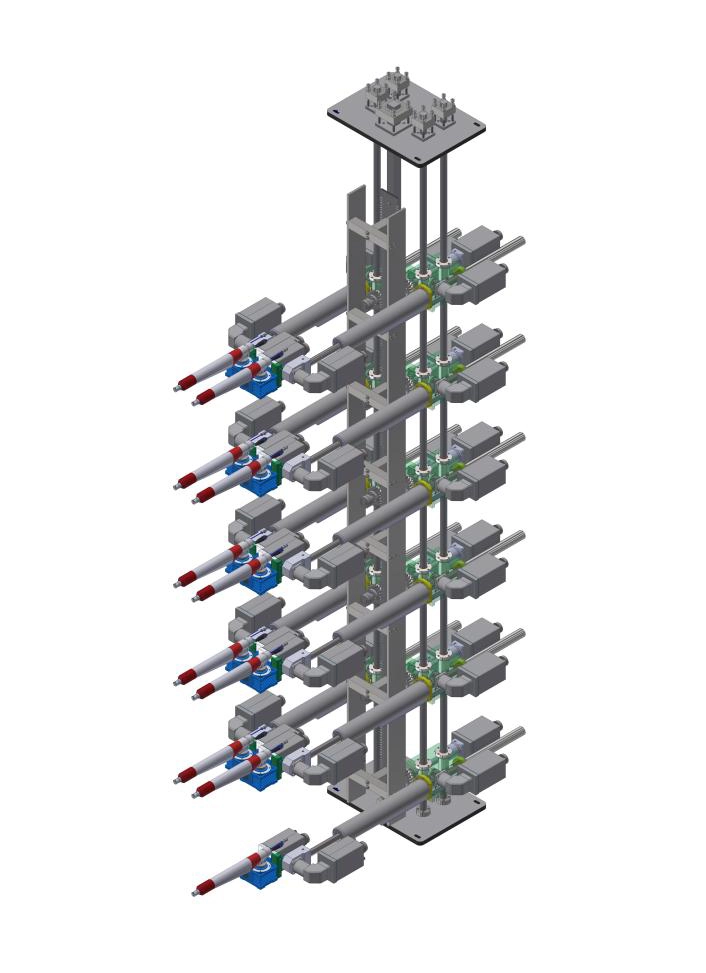

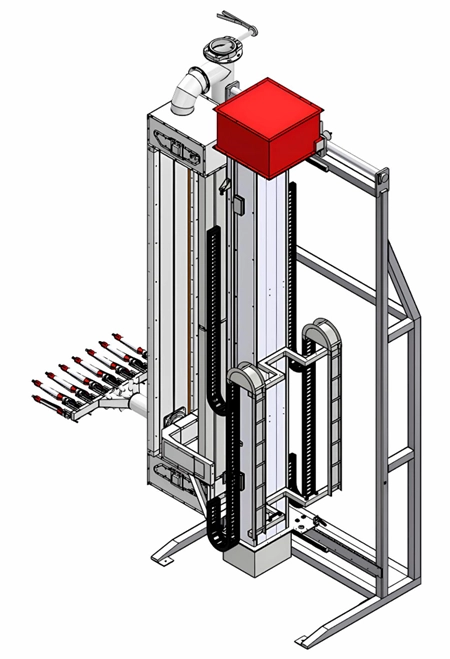

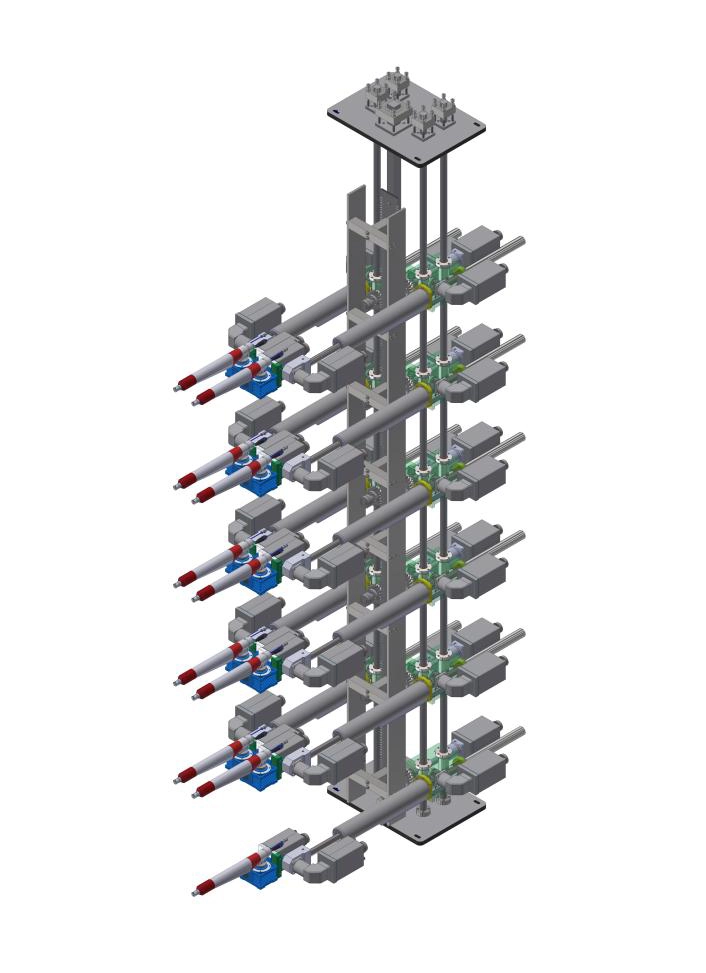

A reciprocator is a motion device used to move spray guns or powder coating applicators back and forth in a controlled linear path. This repetitive motion covers wide areas evenly and efficiently, making it crucial in automated coating systems.

Basic Working Principle

The reciprocator moves a spray gun steadily across the target object, ensuring consistent powder application. Controlled speed and stroke length prevent excessive coating buildup or uneven coverage.

Components of a Reciprocator System

- Motor or actuator driving the motion

- Guide rails for smooth linear travel

- Control unit to set speed, stroke length, and dwell time

- Mounting fixtures for spray guns or applicators

How Reciprocators Improve Powder Coating Automation

Reciprocators enhance automation by providing precise, repeatable, and adjustable motion that integrates easily with powder coating booths and robots.

Uniform Coating Thickness

By maintaining a steady reciprocating motion, powder is applied evenly across surfaces, avoiding common defects like thick edges or thin spots.

Enhanced Production Speed

Automated reciprocators move spray guns faster and more consistently than human operators, increasing line throughput while maintaining quality.

Integration with Robotic Systems

Reciprocators often complement robotic arms by simplifying movement in one axis, allowing the robot to focus on complex multi-axis adjustments. This synergy improves overall system efficiency.

Reduced Overspray and Waste

Controlled motion means powder is applied precisely where needed, reducing overspray and material waste, which saves costs and reduces environmental impact.

Types of Reciprocators Used in Powder Coating

Various reciprocator types suit different production needs and coating booth configurations.

Pneumatic Reciprocators

Powered by compressed air, pneumatic reciprocators are simple, durable, and widely used. They provide smooth linear motion ideal for standard coating lines.

Electric Reciprocators

Electric models use servo or stepper motors offering precise speed and stroke control. They support programmable automation and are preferred for high-tech production environments.

Hydraulic Reciprocators

Hydraulic reciprocators provide high force and are suitable for heavy-duty industrial applications, although they are less common in powder coating compared to pneumatic and electric types.

Key Features to Look for in Powder Coating Reciprocators

Selecting the right reciprocator is vital for process optimization.

Adjustable Stroke Length and Speed

Allows customization for various part sizes and coating requirements.

Durable Construction

Materials resistant to corrosive powders and industrial environments ensure longevity.

Smooth Motion Control

Minimizes coating defects caused by jerks or vibrations.

Easy Integration

Compatibility with existing automation and control systems enables seamless upgrades.

Practical Applications of Reciprocators in Powder Coating

Reciprocators are used across different industries and coating setups to boost process automation.

Automotive Industry

Automated coating of car parts with reciprocators improves finish consistency and throughput for high-volume manufacturing.

Appliances and Electronics

Powder coating of metal housings and components benefits from reciprocator-controlled spraying for uniform appearance and protection.

Construction and Architecture

Large panels and structural components coated via reciprocators ensure even coverage and reduced labor.

Custom Coating Lines

OEMs integrate reciprocators into bespoke coating cells tailored to client needs for efficient automated application.

Installation and Maintenance of Reciprocators

Proper installation and upkeep extend reciprocator performance and reliability.

Installation Best Practices

- Position reciprocators parallel to coating surfaces

- Ensure secure mounting to prevent vibration

- Calibrate speed and stroke according to part geometry

Routine Maintenance Tips

- Regular lubrication of moving parts

- Frequent inspection of motor and guides

- Calibration checks to maintain precision

Challenges and Solutions When Using Reciprocators

While reciprocators bring many benefits, some challenges must be navigated.

Challenge: Limited Axis Movement

Reciprocators typically operate along a single linear axis, limiting motion flexibility.

Solution: Combine reciprocators with robotic arms or other actuators for multi-axis automation.

Challenge: Wear and Tear

Continuous repetitive motion can cause mechanical wear affecting performance.

Solution: Use high-quality components and establish preventative maintenance schedules.

Challenge: Syncing with Spray Guns

Poor synchronization of spray guns and reciprocator motion can cause coating defects.

Solution: Employ integrated control systems for timing and speed coordination.

Future Trends in Reciprocators for Powder Coating Automation

Emerging technologies continue to evolve reciprocator capabilities.

Smart Sensors and Feedback

Integration of sensors provides real-time monitoring of coating thickness and equipment status, enabling adaptive control.

Advanced Motion Control Algorithms

Improved software allows smoother, more adaptive reciprocation to optimize coverage on complex geometries.

Modular and Scalable Designs

New reciprocators are designed for easy expansion and configuration changes to meet evolving production demands.

Frequently Asked Questions About Reciprocators in Powder Coating

Q1: What is the main benefit of using reciprocators in powder coating automation?

A1: Reciprocators ensure consistent, uniform application of powder coating across surfaces, improving finish quality and reducing waste.

Q2: Can reciprocators work with robotic coating systems?

A2: Yes, reciprocators often complement robotic arms by handling linear motion, enhancing the precision and efficiency of automated coating lines.

Q3: How do pneumatic and electric reciprocators differ?

A3: Pneumatic reciprocators use compressed air and are simpler and less costly, while electric reciprocators offer precise speed and stroke control suitable for advanced automation.

Q4: What maintenance is required for reciprocators?

A4: Regular lubrication, inspections of mechanical parts, and calibration of speed and stroke are necessary to maintain performance and longevity.

Q5: Are reciprocators suitable for coating complex-shaped objects?

A5: Reciprocators primarily provide linear motion and are best for flat or simple geometries. For complex shapes, combining them with robotic arms improves coverage.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.