Content Menu

● Understanding Manual Electrostatic Spray Guns

>> What Are Manual Electrostatic Spray Guns?

>> How Do They Work?

● Advantages of Manual Electrostatic Spray Guns

>> Enhanced Flexibility

>> Cost-Effectiveness

>> Improved Coating Quality

>> Ease of Use

● Applications of Manual Electrostatic Spray Guns

>> Automotive Industry

>> Furniture Manufacturing

>> Appliance Coating

>> Architectural Applications

>> Custom Art and Design

● Maintenance and Best Practices

>> Regular Cleaning

>> Proper Storage

>> Training and Safety

● Future Trends in Manual Electrostatic Spray Guns

● Conclusion

>> Frequently Asked Questions

In the world of powder coating, the ability to adapt to various applications and requirements is crucial. Manual electrostatic spray guns have emerged as a vital tool in this field, offering unparalleled flexibility for custom powder coating projects. This article explores how these innovative devices enhance the powder coating process, their advantages, and their applications across different industries.

Understanding Manual Electrostatic Spray Guns

What Are Manual Electrostatic Spray Guns?

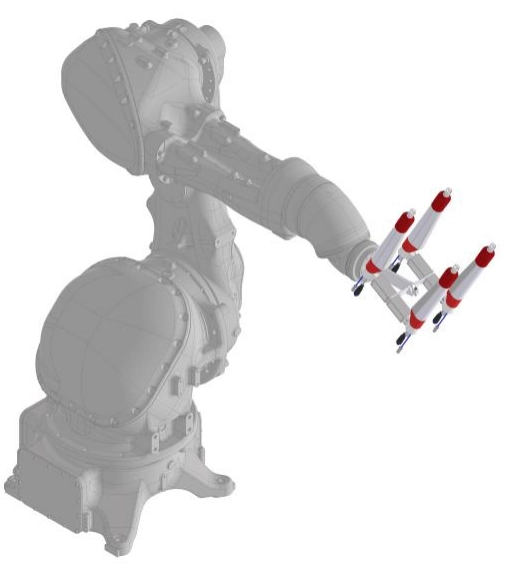

Manual electrostatic spray guns are handheld devices designed to apply powder coatings by electrically charging the powder particles as they are sprayed. This electrostatic charge causes the powder to be attracted to the grounded workpiece, resulting in a uniform coating with minimal overspray. Unlike automated systems, manual guns allow operators to control the application process, making them ideal for custom jobs and intricate designs.

How Do They Work?

The operation of a manual electrostatic spray gun involves several key components:

1. Electrostatic Charge: The gun imparts a negative charge to the powder particles, which are then attracted to the positively grounded surface of the object being coated.

2. Airflow: Compressed air is used to atomize the powder, creating a fine mist that can easily adhere to the surface.

3. Control Mechanisms: Operators can adjust the flow of powder and air pressure, allowing for precise control over the coating process.

This combination of electrostatic charging and manual control enables the application of powder coatings in a variety of settings, from small workshops to large manufacturing facilities.

Advantages of Manual Electrostatic Spray Guns

Enhanced Flexibility

One of the primary benefits of manual electrostatic spray guns is their flexibility. They can be used for a wide range of applications, including:

- Custom Coating: Ideal for unique or one-off projects where specific colors or finishes are required.

- Complex Shapes: Capable of reaching difficult areas and intricate designs that automated systems may struggle with.

- Small Batches: Perfect for low-volume production runs, allowing businesses to cater to specific customer needs without the overhead of automated systems.

Cost-Effectiveness

Manual electrostatic spray guns are generally more affordable than their automated counterparts. This makes them accessible for small businesses and startups that may not have the budget for expensive machinery. Additionally, the reduced overspray associated with electrostatic spraying leads to less waste, further enhancing cost efficiency.

Improved Coating Quality

The electrostatic process ensures that powder particles are evenly distributed across the surface, resulting in a smooth and durable finish. This method minimizes common issues such as uneven coverage and "fatty edges," which can occur with traditional spray painting techniques.

Ease of Use

Manual electrostatic spray guns are designed for user-friendliness. Operators can quickly learn to use these tools effectively, making them suitable for both experienced professionals and newcomers to the powder coating industry. The lightweight design and ergonomic features also reduce operator fatigue during extended use.

Applications of Manual Electrostatic Spray Guns

Automotive Industry

In the automotive sector, manual electrostatic spray guns are used for coating various components, including wheels, frames, and interior parts. The ability to customize colors and finishes allows manufacturers to meet specific design requirements while ensuring a high-quality finish that withstands the rigors of daily use.

Furniture Manufacturing

Furniture manufacturers utilize manual electrostatic spray guns to apply durable coatings to metal and wooden surfaces. The flexibility of these guns enables the application of different colors and textures, catering to diverse customer preferences and trends in interior design.

Appliance Coating

Electrostatic spray guns are commonly used in the appliance industry for coating smaller parts such as knobs, handles, and control panels. The precision offered by manual guns ensures complete coverage, even in hard-to-reach areas, enhancing the overall aesthetic and durability of the appliances.

Architectural Applications

In architecture, manual electrostatic spray guns are employed to coat metal structures, railings, and decorative elements. The ability to achieve a variety of finishes allows architects and designers to create visually appealing and functional spaces.

Custom Art and Design

Artists and designers are increasingly turning to manual electrostatic spray guns for custom projects. The flexibility to experiment with different colors and techniques enables the creation of unique pieces that stand out in the market.

Maintenance and Best Practices

Regular Cleaning

To maintain optimal performance, it is essential to clean the spray gun regularly. This includes cleaning the nozzle, filters, and hoses to prevent clogging and ensure consistent spray quality.

Proper Storage

When not in use, manual electrostatic spray guns should be stored in a dry, clean environment to prevent damage. Keeping the equipment in a protective case can also help extend its lifespan.

Training and Safety

Operators should receive proper training on the use of manual electrostatic spray guns to ensure safety and efficiency. Understanding the electrostatic process and adhering to safety protocols can prevent accidents and improve overall productivity.

Future Trends in Manual Electrostatic Spray Guns

As technology continues to advance, the future of manual electrostatic spray guns looks promising. Innovations may include:

- Smart Technology: Integration of smart features that allow for real-time monitoring and adjustments during the coating process.

- Sustainability: Development of eco-friendly powder coatings and processes that reduce environmental impact.

- Customization Options: Enhanced customization capabilities, allowing users to easily switch between different powder types and colors.

Conclusion

Manual electrostatic spray guns play a crucial role in enhancing flexibility in custom powder coating applications. Their ability to adapt to various needs, combined with cost-effectiveness and improved coating quality, makes them an invaluable tool across multiple industries. As technology evolves, these guns will likely become even more versatile, catering to the growing demand for customized solutions in the powder coating market.

Frequently Asked Questions

1. What is the main advantage of using manual electrostatic spray guns?

- Manual electrostatic spray guns offer greater flexibility for custom applications, allowing for precise control over the coating process.

2. Can manual electrostatic spray guns be used for large production runs?

- While they are ideal for small batches and custom jobs, they can also be used in larger production settings, although automated systems may be more efficient for high-volume applications.

3. How do I maintain my manual electrostatic spray gun?

- Regular cleaning of the nozzle, filters, and hoses is essential, along with proper storage to prevent damage.

4. What industries benefit from manual electrostatic spray guns?

- Industries such as automotive, furniture manufacturing, appliance coating, architecture, and custom art and design all utilize these guns for their flexibility and quality.

5. What future trends can we expect in manual electrostatic spray guns?

- Innovations may include smart technology integration, sustainable practices, and enhanced customization options for users.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.