Content Menu

● Understanding Electrostatic Spray Guns

>> What Are Electrostatic Spray Guns?

>> How Do They Work?

● Environmental Benefits of Electrostatic Spray Guns

>> Reduced Overspray and Waste

>> Lower Volatile Organic Compounds (VOCs) Emissions

>> Improved Energy Efficiency

>> Enhanced Worker Safety

● Economic Advantages of Electrostatic Spray Guns

>> Cost Savings

>> Increased Productivity

>> Improved Quality of Finish

● Applications of Electrostatic Spray Guns

>> Automotive Industry

>> Furniture and Woodworking

>> Industrial Coatings

● Challenges and Considerations

>> Initial Investment

>> Training and Expertise

>> Compatibility with Coatings

● Future Trends in Electrostatic Spray Technology

>> Advancements in Coating Materials

>> Integration with Automation

>> Enhanced Safety Features

● Conclusion

>> Frequently Asked Questions

In recent years, the coating industry has faced increasing scrutiny regarding its environmental impact. Traditional spray painting methods often lead to significant overspray, waste, and harmful emissions. However, the advent of electrostatic spray guns has revolutionized the way coatings are applied, offering a more efficient and environmentally friendly alternative. This article explores how electrostatic spray guns work, their benefits, and their role in reducing environmental impact in the coating process.

Understanding Electrostatic Spray Guns

What Are Electrostatic Spray Guns?

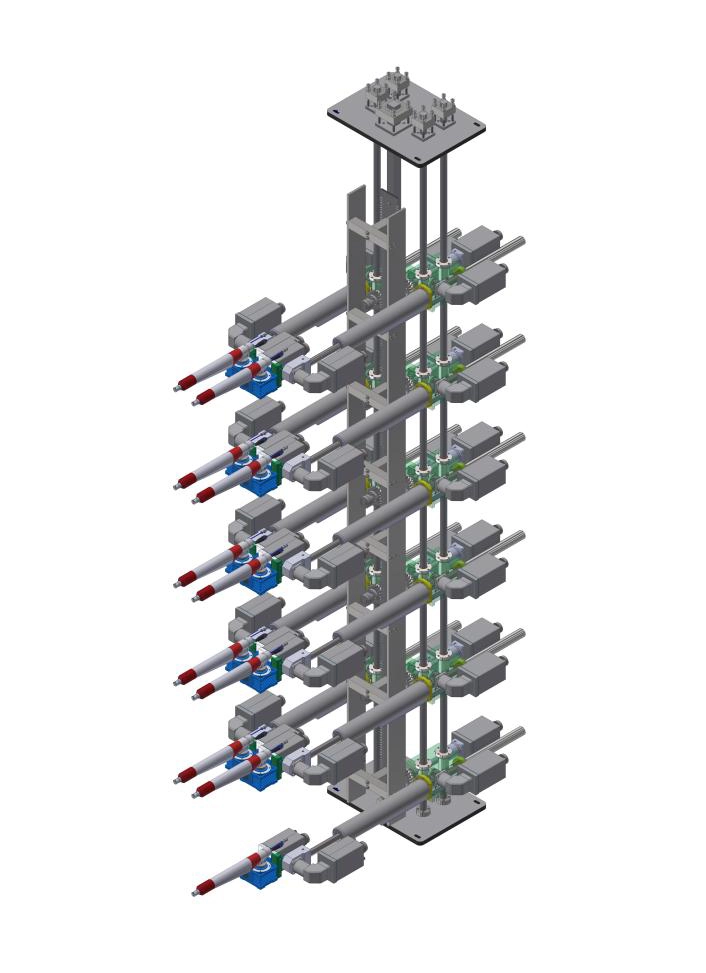

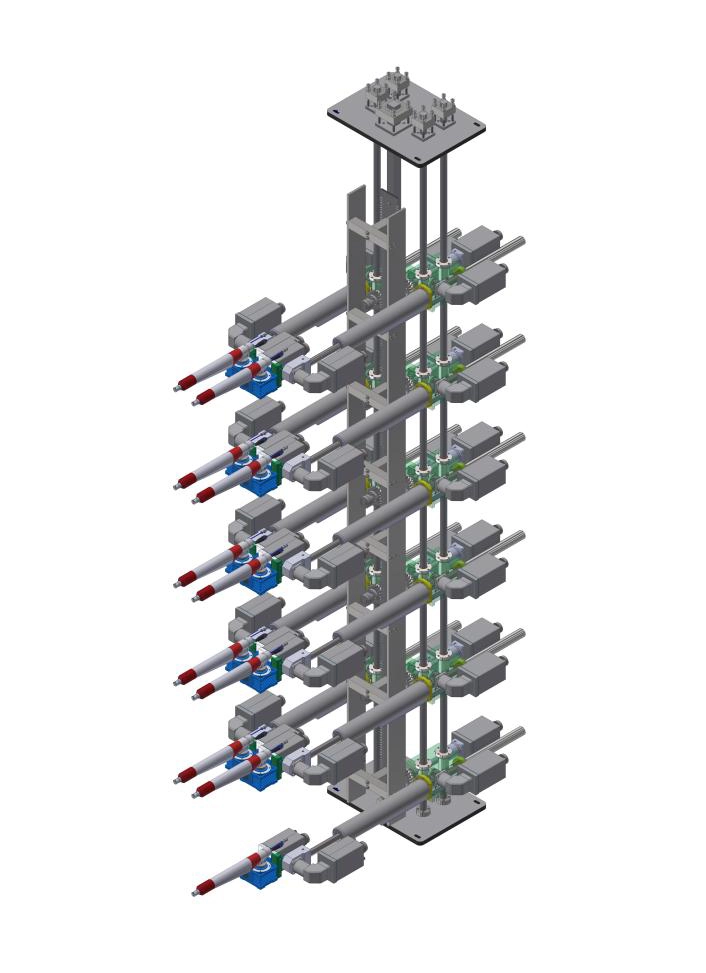

Electrostatic spray guns are specialized tools used for applying paint and other coatings. They utilize electrostatic principles to charge the paint particles as they are sprayed, allowing them to be attracted to the surface being coated. This technology enhances the efficiency of the coating process and minimizes waste.

How Do They Work?

The operation of electrostatic spray guns involves several key components:

1. Electrostatic Charge: The spray gun imparts a positive charge to the paint particles as they exit the nozzle. This charge causes the particles to be attracted to the negatively charged surface of the object being painted.

2. Atomization: The paint is atomized into fine droplets, which helps in achieving a smooth and even coating. The electrostatic charge ensures that these droplets are directed towards the surface, reducing overspray.

3. Surface Attraction: The charged paint particles are drawn to the surface, allowing for better coverage and adhesion. This attraction minimizes the amount of paint that escapes into the air, reducing waste and emissions.

Environmental Benefits of Electrostatic Spray Guns

Reduced Overspray and Waste

One of the most significant advantages of electrostatic spray guns is their ability to reduce overspray. Traditional spray painting methods can result in up to 50% of the paint being wasted due to overspray. In contrast, electrostatic spray guns can achieve transfer efficiencies of 90% or higher. This means that more of the paint applied actually adheres to the surface, significantly reducing waste.

Lower Volatile Organic Compounds (VOCs) Emissions

Volatile organic compounds (VOCs) are harmful chemicals commonly found in paints and coatings. When these substances evaporate, they contribute to air pollution and can have adverse health effects. Electrostatic spray guns can help reduce VOC emissions in several ways:

1. Efficient Application: By minimizing overspray, electrostatic spray guns reduce the amount of paint that evaporates into the air.

2. Water-Based Coatings: Many electrostatic spray systems are compatible with water-based coatings, which typically contain lower levels of VOCs compared to solvent-based paints.

3. Controlled Environment: Electrostatic spray systems can be used in controlled environments, such as spray booths, which further limits the release of VOCs into the atmosphere.

Improved Energy Efficiency

The use of electrostatic spray guns can also lead to improved energy efficiency in the coating process. Traditional spray painting often requires extensive ventilation systems to manage overspray and fumes, which can consume significant amounts of energy. In contrast, electrostatic systems require less ventilation due to their reduced overspray, leading to lower energy consumption and operational costs.

Enhanced Worker Safety

Worker safety is a critical concern in the coating industry. Traditional spray painting methods expose workers to harmful chemicals and fumes, increasing the risk of respiratory issues and other health problems. Electrostatic spray guns help mitigate these risks by:

1. Reducing Fume Exposure: With less overspray and VOC emissions, workers are exposed to fewer harmful substances.

2. Improved Air Quality: The use of water-based coatings and controlled environments contributes to better air quality in the workplace.

3. Safer Handling: Many modern electrostatic spray guns are designed with safety features that minimize the risk of accidents during operation.

Economic Advantages of Electrostatic Spray Guns

Cost Savings

While the initial investment in electrostatic spray technology may be higher than traditional methods, the long-term cost savings can be substantial. The reduction in paint waste, lower energy consumption, and decreased need for extensive ventilation systems can lead to significant savings over time.

Increased Productivity

Electrostatic spray guns can enhance productivity in several ways:

1. Faster Application: The efficient transfer of paint allows for quicker application, reducing the time required for each job.

2. Less Cleanup: With reduced overspray, there is less need for cleanup, allowing workers to focus on the task at hand.

3. Versatility: Electrostatic spray guns can be used on a variety of surfaces and materials, making them suitable for a wide range of applications.

Improved Quality of Finish

The precision of electrostatic spray guns leads to a higher quality finish. The even distribution of paint results in a smoother surface with fewer defects, reducing the need for rework and touch-ups. This not only enhances the final product but also improves customer satisfaction.

Applications of Electrostatic Spray Guns

Automotive Industry

The automotive industry has been one of the early adopters of electrostatic spray technology. The ability to achieve a high-quality finish with minimal waste makes electrostatic spray guns ideal for painting vehicles. Additionally, the reduced VOC emissions align with the industry's push towards more sustainable practices.

Furniture and Woodworking

In the furniture and woodworking industries, electrostatic spray guns are used to apply finishes to a variety of surfaces. The technology allows for even coverage on intricate designs and shapes, ensuring a professional appearance while minimizing waste.

Industrial Coatings

Electrostatic spray guns are also widely used in industrial coatings, including machinery and equipment. The ability to apply coatings efficiently and with minimal environmental impact makes them a preferred choice for manufacturers looking to enhance their sustainability efforts.

Challenges and Considerations

Initial Investment

While the long-term benefits of electrostatic spray guns are clear, the initial investment can be a barrier for some businesses. Companies must weigh the upfront costs against the potential savings and environmental benefits.

Training and Expertise

Implementing electrostatic spray technology may require additional training for workers. Understanding the principles of electrostatics and how to operate the equipment effectively is crucial for maximizing the benefits of this technology.

Compatibility with Coatings

Not all coatings are suitable for electrostatic application. Businesses must ensure that the paints and finishes they use are compatible with electrostatic spray guns to achieve optimal results.

Future Trends in Electrostatic Spray Technology

Advancements in Coating Materials

As the demand for environmentally friendly coatings continues to grow, manufacturers are developing new materials that are compatible with electrostatic spray technology. Innovations in water-based and low-VOC coatings will further enhance the environmental benefits of electrostatic spray guns.

Integration with Automation

The integration of electrostatic spray guns with automated systems is a growing trend in the coating industry. Automation can improve efficiency, consistency, and quality while further reducing waste and environmental impact.

Enhanced Safety Features

Future developments in electrostatic spray technology are likely to focus on enhancing safety features. This includes improved ventilation systems, better personal protective equipment, and advanced monitoring systems to ensure worker safety.

Conclusion

Electrostatic spray guns represent a significant advancement in the coating industry, offering numerous environmental and economic benefits. By reducing overspray, lowering VOC emissions, and improving energy efficiency, these tools help companies minimize their environmental impact while enhancing productivity and quality. As technology continues to evolve, the role of electrostatic spray guns in promoting sustainable practices will only become more critical.

Frequently Asked Questions

1. What is the main advantage of using electrostatic spray guns?

- The main advantage is their ability to reduce overspray and waste, leading to more efficient paint application and lower environmental impact.

2. How do electrostatic spray guns reduce VOC emissions?

- They minimize overspray and can be used with water-based coatings, which typically contain lower levels of VOCs.

3. Are electrostatic spray guns safe for workers?

- Yes, they reduce exposure to harmful chemicals and improve air quality, enhancing worker safety.

4. What industries commonly use electrostatic spray guns?

- Common industries include automotive, furniture and woodworking, and industrial coatings.

5. What challenges are associated with electrostatic spray guns?

- Challenges include the initial investment cost, the need for worker training, and ensuring compatibility with coatings.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.