Content Menu

● Understanding Electrostatic Spray Technology

>> What is Electrostatic Spray?

>> How Automatic Systems Work

● Benefits of Automatic Electrostatic Spray Gun Systems

>> Increased Efficiency

>> Cost Savings

>> Improved Quality

>> Environmental Benefits

● Challenges of Implementing Automatic Systems

>> Initial Investment Costs

>> Training and Integration

>> Maintenance and Upkeep

● Calculating ROI for Automatic Electrostatic Spray Systems

>> Factors to Consider

>> ROI Calculation Formula

● Case Studies: Success Stories in Large-Scale Production

>> Automotive Industry

>> Furniture Manufacturing

>> Aerospace Sector

● Future Trends in Electrostatic Spray Technology

>> Advancements in Automation

>> Integration with Industry 4.0

>> Sustainability Initiatives

● Conclusion

>> Frequently Asked Questions

In the realm of manufacturing, efficiency and cost-effectiveness are paramount. As industries strive to optimize their production processes, the adoption of advanced technologies becomes essential. One such technology that has gained significant traction is the automatic electrostatic spray gun system. This article delves into the return on investment (ROI) of these systems in large-scale production environments, examining their benefits, challenges, and overall impact on manufacturing efficiency.

Understanding Electrostatic Spray Technology

What is Electrostatic Spray?

Electrostatic spray technology involves the use of charged particles to enhance the application of coatings, paints, and other materials. The process works by charging the spray particles, which are then attracted to the grounded surface of the object being coated. This method not only improves the efficiency of the coating process but also reduces waste and overspray.

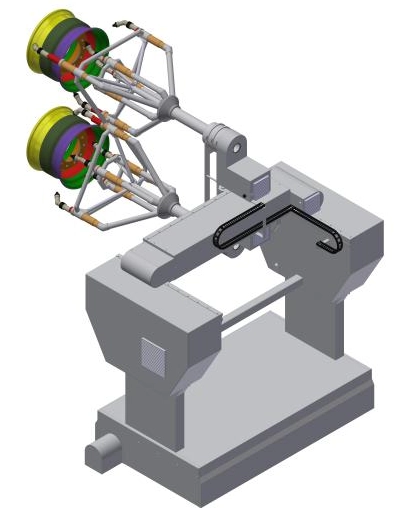

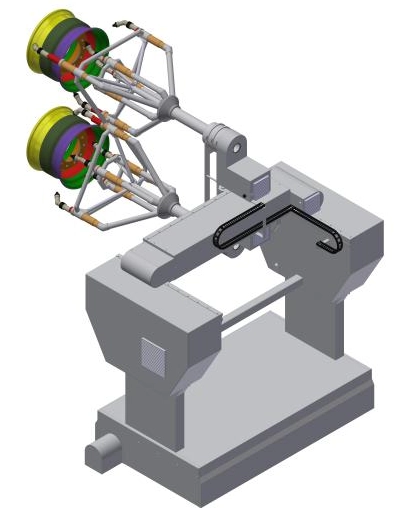

How Automatic Systems Work

Automatic electrostatic spray gun systems are designed to operate with minimal human intervention. These systems utilize advanced robotics and control technologies to ensure consistent application of coatings. The automation of the spraying process allows for precise control over the amount of material used, the speed of application, and the overall quality of the finish.

Benefits of Automatic Electrostatic Spray Gun Systems

Increased Efficiency

One of the primary advantages of automatic electrostatic spray gun systems is their ability to significantly increase production efficiency. By automating the spraying process, manufacturers can achieve faster application times and reduce the need for manual labor. This efficiency translates into higher output rates and the ability to meet production demands more effectively.

Cost Savings

The implementation of automatic electrostatic spray systems can lead to substantial cost savings. These systems minimize material waste through their precise application techniques, ensuring that coatings are applied only where needed. Additionally, the reduction in labor costs associated with manual spraying can further enhance the overall ROI.

Improved Quality

Quality control is a critical aspect of manufacturing, and automatic electrostatic spray systems excel in this area. The consistency of the spray application leads to a more uniform finish, reducing the likelihood of defects and the need for rework. This improvement in quality not only enhances customer satisfaction but also contributes to long-term cost savings.

Environmental Benefits

In an era where sustainability is increasingly important, automatic electrostatic spray systems offer environmental advantages. The reduction in overspray and material waste contributes to a lower environmental impact. Furthermore, many of these systems are designed to work with eco-friendly coatings, aligning with the growing demand for sustainable manufacturing practices.

Challenges of Implementing Automatic Systems

Initial Investment Costs

While the long-term benefits of automatic electrostatic spray systems are clear, the initial investment can be a barrier for some manufacturers. The cost of purchasing and installing these systems can be significant, and companies must carefully evaluate their financial capabilities before making such an investment.

Training and Integration

Transitioning to an automatic system requires training for existing staff and may necessitate changes in production workflows. Manufacturers must invest time and resources into training employees to operate and maintain the new equipment effectively. Additionally, integrating these systems into existing production lines can pose logistical challenges.

Maintenance and Upkeep

Like any advanced technology, automatic electrostatic spray systems require regular maintenance to ensure optimal performance. Manufacturers must be prepared to allocate resources for ongoing maintenance and potential repairs, which can impact the overall ROI if not managed effectively.

Calculating ROI for Automatic Electrostatic Spray Systems

Factors to Consider

When evaluating the ROI of automatic electrostatic spray systems, several factors must be taken into account:

1. Initial Costs: This includes the purchase price of the equipment, installation costs, and any necessary modifications to existing production lines.

2. Operational Costs: Consider ongoing expenses such as maintenance, labor, and materials.

3. Production Output: Analyze the increase in production rates and the potential for meeting higher demand.

4. Quality Improvements: Assess the reduction in defects and rework costs associated with improved quality.

5. Environmental Impact: Factor in any potential savings from reduced waste and compliance with environmental regulations.

ROI Calculation Formula

To calculate the ROI, manufacturers can use the following formula:

ROI=Net ProfitTotal Investment×100ROI=Total InvestmentNet Profit×100

Where:

Net Profit is the total revenue generated from increased production minus the operational costs.

Total Investment includes all initial and ongoing costs associated with the automatic electrostatic spray system.

Case Studies: Success Stories in Large-Scale Production

Automotive Industry

In the automotive sector, manufacturers have successfully implemented automatic electrostatic spray systems to enhance their painting processes. By automating the application of coatings, companies have reported significant reductions in material waste and labor costs, leading to a rapid return on investment.

Furniture Manufacturing

Furniture manufacturers have also embraced this technology to improve their finishing processes. The ability to achieve a consistent and high-quality finish has not only improved customer satisfaction but has also reduced the time required for production, allowing companies to increase their output.

Aerospace Sector

The aerospace industry, known for its stringent quality standards, has benefited from the precision of automatic electrostatic spray systems. By ensuring a uniform application of coatings, manufacturers have minimized defects and enhanced the durability of their products, resulting in long-term cost savings.

Future Trends in Electrostatic Spray Technology

Advancements in Automation

As technology continues to evolve, we can expect further advancements in automation within electrostatic spray systems. Innovations such as artificial intelligence and machine learning may enhance the precision and efficiency of these systems, leading to even greater ROI for manufacturers.

Integration with Industry 4.0

The integration of electrostatic spray systems with Industry 4.0 technologies will enable manufacturers to optimize their production processes further. Real-time data analytics and connectivity will allow for better monitoring and control of the spraying process, enhancing overall efficiency and quality.

Sustainability Initiatives

With the growing emphasis on sustainability, future developments in electrostatic spray technology will likely focus on eco-friendly materials and processes. Manufacturers will increasingly seek solutions that not only improve efficiency but also align with environmental goals.

Conclusion

The adoption of automatic electrostatic spray gun systems presents a compelling opportunity for manufacturers seeking to enhance their production processes. While the initial investment may be significant, the long-term benefits in terms of efficiency, cost savings, and quality improvements make these systems a worthwhile consideration. As technology continues to advance, the ROI of these systems is expected to improve further, solidifying their place in large-scale production environments.

Frequently Asked Questions

1. What are the main advantages of using automatic electrostatic spray systems?

- The main advantages include increased efficiency, cost savings, improved quality, and environmental benefits.

2. What challenges might a manufacturer face when implementing these systems?

- Challenges include initial investment costs, the need for staff training, and ongoing maintenance requirements.

3. How can ROI be calculated for automatic electrostatic spray systems?

- ROI can be calculated using the formula: ROI = (Net Profit / Total Investment) × 100, considering factors like initial costs, operational costs, and production output.

4. What industries have successfully implemented these systems?

- Industries such as automotive, furniture manufacturing, and aerospace have successfully adopted automatic electrostatic spray systems.

5. What future trends can we expect in electrostatic spray technology?

- Future trends may include advancements in automation, integration with Industry 4.0 technologies, and a focus on sustainability initiatives.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.