Content Menu

● Understanding Electrostatic Spray Guns

>> What is an Electrostatic Spray Gun?

>> How Do Electrostatic Spray Guns Work?

● Benefits of Manual Electrostatic Spray Guns

>> Increased Efficiency

>> Reduced Overspray

>> Improved Finish Quality

>> Versatility

>> Environmentally Friendly

● Applications of Manual Electrostatic Spray Guns

>> Automotive Industry

>> Industrial Coatings

>> Furniture and Cabinetry

>> Aerospace

● Key Features to Consider When Buying a Manual Electrostatic Spray Gun

>> Type of Gun

>> Voltage Output

>> Material Compatibility

>> Weight and Ergonomics

>> Maintenance Requirements

● Maintenance Tips for Manual Electrostatic Spray Guns

>> Regular Cleaning

>> Inspect for Wear and Tear

>> Store Properly

>> Check Electrical Components

>> Follow Manufacturer Guidelines

● Conclusion

>> Frequently Asked Questions

Electrostatic spray guns have revolutionized the painting and coating industry, providing a more efficient and effective way to apply finishes. If you're considering investing in a manual electrostatic spray gun, it's essential to understand how they work, their benefits, and what to look for when making a purchase. This comprehensive guide will cover everything you need to know about manual electrostatic spray guns, including their operation, advantages, applications, and maintenance.

Understanding Electrostatic Spray Guns

What is an Electrostatic Spray Gun?

An electrostatic spray gun is a device that uses electrostatic charge to attract paint particles to a surface. This technology enhances the efficiency of the painting process by ensuring that more paint adheres to the target surface, reducing overspray and waste. The gun charges the paint particles as they exit the nozzle, causing them to be attracted to the grounded object being painted.

How Do Electrostatic Spray Guns Work?

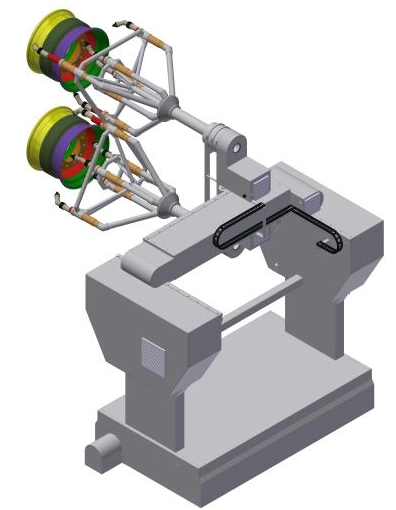

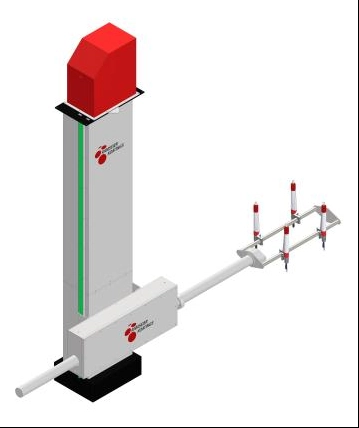

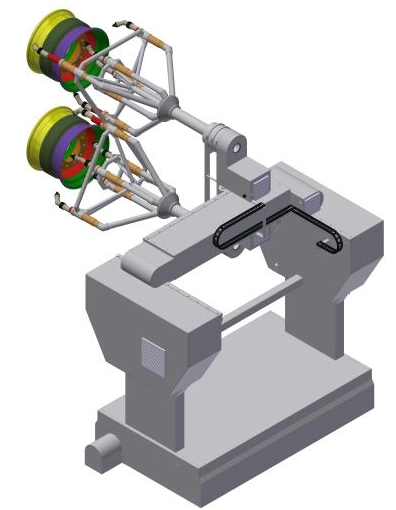

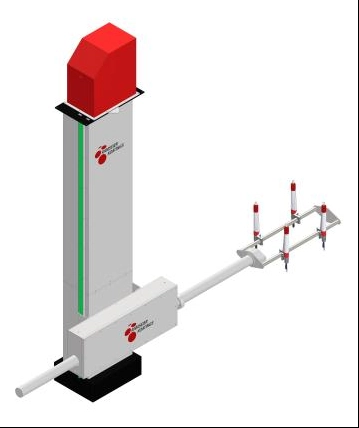

The operation of an electrostatic spray gun involves several key components:

1. Power Supply: The power supply generates a high-voltage charge, typically between 30,000 to 100,000 volts, which is applied to the paint particles.

2. Spray Gun: The spray gun atomizes the paint and applies the electrostatic charge to the particles as they exit the nozzle.

3. Grounded Surface: The object being painted is grounded, creating a magnetic attraction between the charged paint particles and the surface.

This process results in a more uniform coating and can significantly reduce the amount of paint needed for a job.

Benefits of Manual Electrostatic Spray Guns

Increased Efficiency

One of the primary advantages of using a manual electrostatic spray gun is the increased efficiency in paint application. The electrostatic charge allows for better coverage, meaning less paint is wasted. This efficiency can lead to significant cost savings over time, especially for large projects.

Reduced Overspray

Traditional spray methods often result in overspray, where paint lands on unintended surfaces. Electrostatic spray guns minimize this issue by attracting the paint directly to the surface being coated. This not only saves material but also reduces cleanup time and the need for masking.

Improved Finish Quality

The electrostatic process creates a more even and consistent finish. The charged particles are drawn to the surface, ensuring that even hard-to-reach areas receive adequate coverage. This results in a smoother, more professional-looking finish.

Versatility

Manual electrostatic spray guns can be used with a variety of coatings, including paints, primers, and stains. This versatility makes them suitable for various applications, from automotive refinishing to industrial coatings.

Environmentally Friendly

By reducing overspray and waste, electrostatic spray guns are more environmentally friendly than traditional spray methods. They help minimize the amount of volatile organic compounds (VOCs) released into the atmosphere, making them a more sustainable choice for painting.

Applications of Manual Electrostatic Spray Guns

Automotive Industry

In the automotive industry, electrostatic spray guns are widely used for painting vehicles and parts. The ability to achieve a high-quality finish with minimal waste makes them ideal for automotive refinishing and manufacturing.

Industrial Coatings

Electrostatic spray guns are also popular in industrial settings for coating machinery, equipment, and structural components. Their efficiency and versatility allow for quick and effective application of protective coatings.

Furniture and Cabinetry

In the furniture and cabinetry industry, electrostatic spray guns are used to apply finishes to wood and metal surfaces. The ability to achieve a smooth, even coat is crucial for high-quality furniture production.

Aerospace

The aerospace industry utilizes electrostatic spray guns for applying coatings to aircraft components. The precision and efficiency of these guns are essential for meeting the stringent quality standards in aerospace manufacturing.

Key Features to Consider When Buying a Manual Electrostatic Spray Gun

Type of Gun

There are various types of electrostatic spray guns available, including conventional and high-volume low-pressure (HVLP) models. Consider the type of projects you will be working on to determine which gun is best suited for your needs.

Voltage Output

The voltage output of the spray gun is a critical factor in its performance. Higher voltage can lead to better atomization and coverage, but it may also require more careful handling to avoid safety issues.

Material Compatibility

Ensure that the spray gun you choose is compatible with the types of coatings you plan to use. Some guns are designed for specific materials, while others offer more versatility.

Weight and Ergonomics

Since manual electrostatic spray guns are handheld, consider the weight and ergonomics of the gun. A lightweight, well-balanced gun will reduce fatigue during extended use.

Maintenance Requirements

Look for a spray gun that is easy to clean and maintain. Regular maintenance is essential for ensuring the longevity and performance of your equipment.

Maintenance Tips for Manual Electrostatic Spray Guns

Regular Cleaning

After each use, clean the spray gun thoroughly to prevent paint buildup and clogging. Follow the manufacturer's instructions for disassembly and cleaning procedures.

Inspect for Wear and Tear

Regularly inspect the gun for any signs of wear or damage. Replace any worn parts promptly to maintain optimal performance.

Store Properly

When not in use, store the spray gun in a clean, dry place. Use protective covers to prevent dust and debris from entering the gun.

Check Electrical Components

Periodically check the electrical components of the spray gun, including the power supply and wiring, to ensure they are functioning correctly.

Follow Manufacturer Guidelines

Always refer to the manufacturer's guidelines for specific maintenance and care instructions. This will help you avoid common issues and extend the life of your spray gun.

Conclusion

Investing in a manual electrostatic spray gun can significantly enhance your painting and coating projects. With their efficiency, reduced overspray, and improved finish quality, these guns are a valuable addition to any professional or DIY toolkit. By understanding how they work, their benefits, and what to look for when purchasing, you can make an informed decision that will lead to successful outcomes in your painting endeavors.

Frequently Asked Questions

1. What types of coatings can be used with electrostatic spray guns?

Electrostatic spray guns can be used with a variety of coatings, including paints, primers, and stains, making them versatile for different applications.

2. How do I maintain my electrostatic spray gun?

Regular cleaning, inspecting for wear and tear, proper storage, checking electrical components, and following manufacturer guidelines are essential for maintaining your spray gun.

3. What is the difference between conventional and HVLP electrostatic spray guns?

Conventional spray guns typically use higher pressure to atomize paint, while HVLP guns use lower pressure, resulting in less overspray and a more controlled application.

4. Can I use an electrostatic spray gun for outdoor projects?

Yes, electrostatic spray guns can be used for outdoor projects, but it's essential to consider environmental factors such as wind, which can affect the application.

5. Are electrostatic spray guns safe to use?

While electrostatic spray guns are generally safe, it's crucial to follow safety guidelines, including wearing appropriate personal protective equipment and ensuring proper ventilation during use.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.