Content Menu

● Understanding the Basics

>> What is Electrostatic Spray Gun Coating?

>> What is Liquid Coating?

● The Coating Process

>> Electrostatic Spray Coating Process

>> Liquid Coating Process

● Advantages of Electrostatic Spray Gun Coating

>> High Transfer Efficiency

>> Reduced Overspray

>> Superior Finish Quality

>> Versatility

● Disadvantages of Electrostatic Spray Gun Coating

>> Initial Cost

>> Limited to Conductive Surfaces

>> Complexity of Equipment

● Advantages of Liquid Coating

>> Lower Initial Investment

>> Simplicity of Application

>> Wide Range of Materials

● Disadvantages of Liquid Coating

>> Higher Overspray and Waste

>> Longer Drying Times

>> Environmental Concerns

● Applications of Each Coating Method

>> When to Use Electrostatic Spray Coating

>> When to Use Liquid Coating

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of electrostatic spray coating?

>> 2. Can electrostatic spray guns be used on non-conductive surfaces?

>> 3. How does the drying time compare between the two methods?

>> 4. Is electrostatic spray coating more environmentally friendly?

>> 5. What industries benefit most from electrostatic spray coating?

In the world of industrial painting and coating, the choice between electrostatic spray gun coating and traditional liquid coating is a significant one. Each method has its unique advantages and disadvantages, making it essential for manufacturers and DIY enthusiasts alike to understand the differences. This article will explore both techniques in detail, comparing their processes, benefits, drawbacks, and applications to help you determine which is better for your specific needs.

Understanding the Basics

What is Electrostatic Spray Gun Coating?

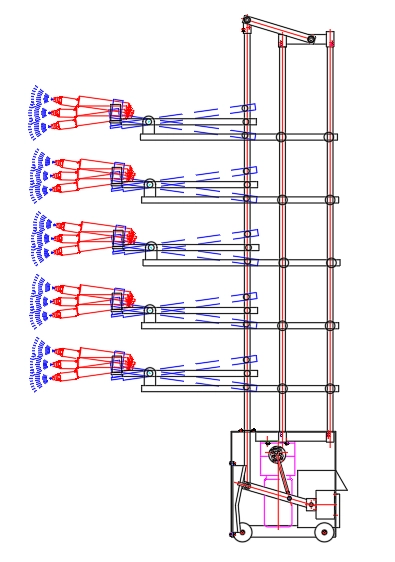

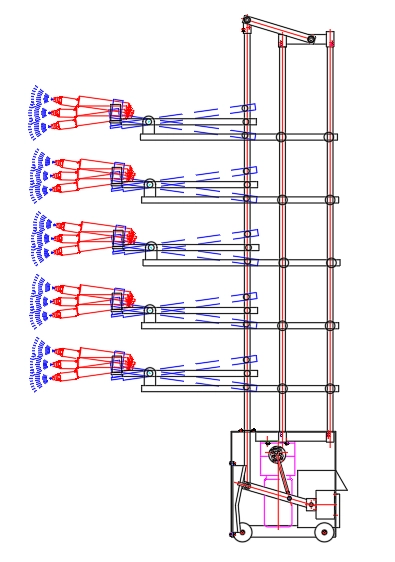

Electrostatic spray gun coating is a method that uses an electric charge to apply paint or powder coatings to a surface. The paint particles are positively charged as they exit the spray gun, while the object being coated is grounded. This creates an attraction between the charged particles and the surface, allowing for a more efficient application with less overspray.

What is Liquid Coating?

Liquid coating, on the other hand, involves applying a liquid paint directly onto a surface using various methods, such as spray guns, brushes, or rollers. This traditional method does not utilize electrical charges, relying instead on the physical properties of the paint and the application technique to achieve coverage.

The Coating Process

Electrostatic Spray Coating Process

1. Preparation: The surface to be coated must be cleaned and prepped to ensure proper adhesion.

2. Charging: The electrostatic spray gun charges the paint particles as they are sprayed.

3. Application: The charged particles are attracted to the grounded surface, resulting in a uniform coating.

4. Curing: If using powder coating, the coated item is then heated in an oven to cure the paint, creating a durable finish.

Liquid Coating Process

1. Surface Preparation: Similar to electrostatic coating, the surface must be cleaned and primed if necessary.

2. Application: Liquid paint is applied using a spray gun, brush, or roller. The application can be done in multiple layers for better coverage.

3. Drying: The liquid paint dries through evaporation or chemical reactions, depending on the type of paint used.

Advantages of Electrostatic Spray Gun Coating

High Transfer Efficiency

One of the most significant benefits of electrostatic spray coating is its high transfer efficiency. The charged particles are attracted to the surface, which means that more paint ends up on the object rather than in the air. This can lead to a reduction in paint usage and lower costs.

Reduced Overspray

Electrostatic spray guns produce less overspray compared to traditional methods. This not only saves material but also minimizes the environmental impact by reducing volatile organic compounds (VOCs) released into the atmosphere.

Superior Finish Quality

The electrostatic process often results in a smoother and more uniform finish. The attraction of the paint particles to the surface helps to eliminate common issues such as drips and uneven coverage.

Versatility

Electrostatic spray guns can be used with various materials, including powder coatings and liquid paints. This versatility makes them suitable for a wide range of applications, from automotive to industrial coatings.

Disadvantages of Electrostatic Spray Gun Coating

Initial Cost

The initial investment for electrostatic spray equipment can be higher than that for traditional liquid coating systems. However, this cost can be offset by savings in material usage and labor over time.

Limited to Conductive Surfaces

Electrostatic spray coating is most effective on conductive surfaces. Non-conductive materials may require additional steps, such as applying a conductive primer, which can complicate the process.

Complexity of Equipment

The equipment used for electrostatic spraying can be more complex and may require specialized training to operate effectively. This can be a barrier for some users.

Advantages of Liquid Coating

Lower Initial Investment

Liquid coating systems typically have a lower upfront cost compared to electrostatic systems. This makes them more accessible for small businesses or DIY projects.

Simplicity of Application

Liquid coatings can be applied using a variety of methods, including brushes and rollers, making them versatile and easy to use for many applications.

Wide Range of Materials

Liquid coatings can be used on a broader range of materials, including non-conductive surfaces, without the need for additional preparation steps.

Disadvantages of Liquid Coating

Higher Overspray and Waste

Liquid coating methods often result in higher overspray, leading to increased material waste and higher costs in the long run.

Longer Drying Times

Liquid coatings typically require longer drying times compared to electrostatic powder coatings, which can slow down production processes.

Environmental Concerns

Many liquid paints contain VOCs, which can contribute to air pollution and pose health risks. This is a significant consideration in today's environmentally conscious market.

Applications of Each Coating Method

When to Use Electrostatic Spray Coating

Electrostatic spray coating is ideal for applications where high efficiency and a superior finish are required. Industries such as automotive, aerospace, and furniture manufacturing often utilize this method due to its ability to provide a durable and attractive finish with minimal waste.

When to Use Liquid Coating

Liquid coating is suitable for projects where cost is a primary concern or where the surfaces being coated are non-conductive. It is commonly used in residential painting, small-scale manufacturing, and DIY projects.

Conclusion

Choosing between electrostatic spray gun coating and liquid coating ultimately depends on your specific needs, budget, and the materials you are working with. Electrostatic spray coating offers superior efficiency, reduced waste, and a high-quality finish, making it an excellent choice for industrial applications. However, for smaller projects or those with budget constraints, liquid coating remains a viable and effective option.

Frequently Asked Questions

1. What is the main advantage of electrostatic spray coating?

The main advantage of electrostatic spray coating is its high transfer efficiency, which reduces material waste and provides a more uniform finish.

2. Can electrostatic spray guns be used on non-conductive surfaces?

Yes, but non-conductive surfaces may require a conductive primer to enhance adhesion and effectiveness.

3. How does the drying time compare between the two methods?

Liquid coatings generally have longer drying times compared to electrostatic powder coatings, which cure quickly in an oven.

4. Is electrostatic spray coating more environmentally friendly?

Yes, electrostatic spray coating typically produces less overspray and lower VOC emissions, making it a more environmentally friendly option.

5. What industries benefit most from electrostatic spray coating?

Industries such as automotive, aerospace, and furniture manufacturing benefit significantly from electrostatic spray coating due to its efficiency and quality.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.