Content Menu

● Understanding Manual Electrostatic Spray Guns

>> What is an Electrostatic Spray Gun?

>> How Do Manual Electrostatic Spray Guns Work?

● Eco-Friendly Benefits of Manual Electrostatic Spray Guns

>> 1. Reduced Paint Waste

>> 2. Lower Volatile Organic Compounds (VOCs) Emissions

>> 3. Enhanced Coating Quality

>> 4. Energy Efficiency

>> 5. Versatility in Applications

>> 6. Improved Worker Safety

● The Future of Eco-Friendly Coating Technologies

>> The Role of Regulations in Promoting Eco-Friendly Practices

● Conclusion

>> Frequently Asked Questions

In recent years, the push for sustainable practices in various industries has led to a significant shift towards eco-friendly technologies. One such innovation is the manual electrostatic spray gun, which has gained popularity for its efficiency and environmental benefits. This article explores the eco-friendly advantages of using manual electrostatic spray guns, their operational principles, applications, and how they contribute to a greener future.

Understanding Manual Electrostatic Spray Guns

What is an Electrostatic Spray Gun?

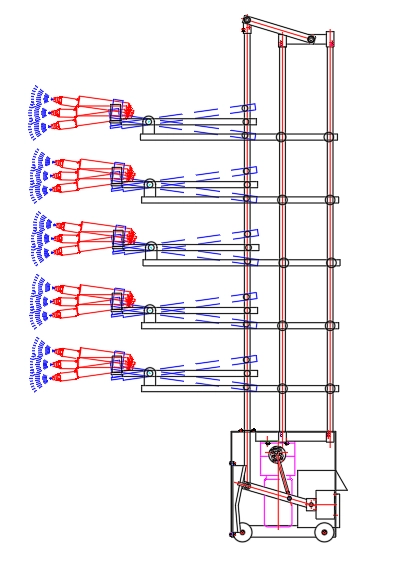

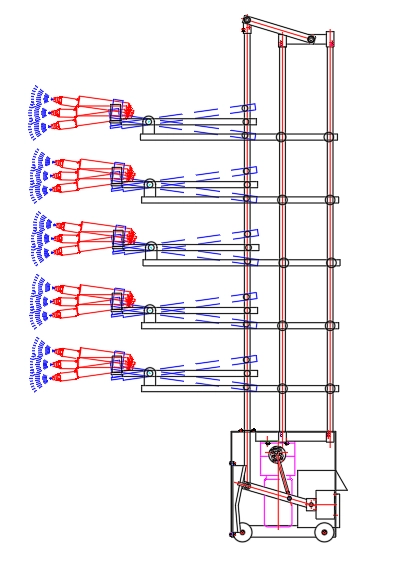

An electrostatic spray gun is a device that uses electrostatic charge to improve the efficiency of paint and coating application. The gun charges the paint particles as they exit the nozzle, causing them to be attracted to the surface being coated. This technology minimizes overspray and waste, making it a preferred choice for many industries.

How Do Manual Electrostatic Spray Guns Work?

Manual electrostatic spray guns operate by applying a high voltage to the paint particles. When the paint is atomized, it receives a positive charge, while the surface being painted is grounded or negatively charged. This creates an attractive force that pulls the paint particles towards the surface, ensuring a more uniform and efficient application.

Eco-Friendly Benefits of Manual Electrostatic Spray Guns

1. Reduced Paint Waste

One of the most significant eco-friendly benefits of using manual electrostatic spray guns is the reduction in paint waste. Traditional spray methods often result in overspray, where a considerable amount of paint is lost to the surrounding environment. In contrast, electrostatic spray guns can achieve transfer efficiencies of up to 90% or more. This means that a larger percentage of the paint reaches the intended surface, reducing the amount of material wasted and minimizing environmental impact.

2. Lower Volatile Organic Compounds (VOCs) Emissions

Volatile Organic Compounds (VOCs) are harmful chemicals found in many paints and coatings. These compounds can evaporate into the atmosphere, contributing to air pollution and posing health risks to humans. Manual electrostatic spray guns can significantly reduce VOC emissions due to their efficient application process. By minimizing overspray and ensuring that more paint adheres to the surface, these guns help lower the overall VOC content released into the environment.

3. Enhanced Coating Quality

The electrostatic charging process not only improves transfer efficiency but also enhances the quality of the coating. The charged paint particles are attracted to the surface, resulting in a more even and consistent application. This leads to fewer defects, such as runs or sags, which can occur with traditional spray methods. A higher quality finish not only looks better but also lasts longer, reducing the need for frequent reapplications and further conserving resources.

4. Energy Efficiency

Manual electrostatic spray guns are designed to be energy efficient. They require less energy to operate compared to conventional spray systems, which often rely on high-pressure air compressors. This reduction in energy consumption not only lowers operational costs but also decreases the carbon footprint associated with the painting process. By choosing electrostatic spray guns, businesses can contribute to energy conservation efforts and promote sustainability.

5. Versatility in Applications

Electrostatic spray guns are versatile tools that can be used in various applications, from automotive painting to industrial coatings and furniture finishing. This adaptability allows businesses to implement eco-friendly practices across multiple sectors. By utilizing a single technology that offers significant environmental benefits, companies can streamline their operations while promoting sustainability.

6. Improved Worker Safety

The use of manual electrostatic spray guns can also enhance worker safety. Traditional spray methods often expose workers to harmful fumes and overspray, which can lead to respiratory issues and other health problems. In contrast, the reduced overspray and lower VOC emissions associated with electrostatic spray guns create a safer working environment. Additionally, many modern electrostatic spray guns are designed with ergonomic features that reduce strain and fatigue, further promoting worker well-being.

The Future of Eco-Friendly Coating Technologies

As industries continue to prioritize sustainability, the demand for eco-friendly technologies like manual electrostatic spray guns is expected to grow. Innovations in this field are likely to focus on improving efficiency, reducing environmental impact, and enhancing user experience. Manufacturers are investing in research and development to create even more advanced electrostatic spray systems that meet the evolving needs of businesses while adhering to environmental regulations.

The Role of Regulations in Promoting Eco-Friendly Practices

Government regulations play a crucial role in encouraging the adoption of eco-friendly technologies. Stricter environmental standards and incentives for using low-VOC products are driving industries to seek out more sustainable options. Manual electrostatic spray guns align with these regulations, making them an attractive choice for companies looking to comply with environmental laws while improving their operational efficiency.

Conclusion

The eco-friendly benefits of using manual electrostatic spray guns are clear. From reducing paint waste and VOC emissions to enhancing coating quality and improving worker safety, these tools represent a significant advancement in sustainable coating technologies. As industries continue to embrace environmentally responsible practices, the adoption of electrostatic spray guns will likely increase, contributing to a greener future for all.

Frequently Asked Questions

1. What are the main advantages of using manual electrostatic spray guns?

Manual electrostatic spray guns offer reduced paint waste, lower VOC emissions, enhanced coating quality, energy efficiency, versatility in applications, and improved worker safety.

2. How do electrostatic spray guns reduce paint waste?

These guns achieve high transfer efficiencies, meaning more paint adheres to the surface rather than being lost to overspray.

3. Are electrostatic spray guns safe for workers?

Yes, they create a safer working environment by reducing harmful fumes and overspray, which can lead to health issues.

4. Can electrostatic spray guns be used in various industries?

Absolutely! They are versatile and can be used in automotive, industrial, and furniture finishing applications, among others.

5. How do regulations impact the use of electrostatic spray guns?

Stricter environmental regulations encourage industries to adopt eco-friendly technologies like electrostatic spray guns to comply with laws and improve sustainability.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.