Content Menu

● Understanding Electrostatic Spray Technology

>> What is Electrostatic Spray?

>> How Does It Work?

● Key Factors in Cost vs Performance

>> Initial Investment

>> Transfer Efficiency

>> Maintenance and Durability

>> Versatility

● Top Automatic Electrostatic Spray Guns

>> 1. 3M Automatic Electrostatic Spray Guns

>>> Overview

>>> Key Features

>>> Advantages

>>> Limitations

>> 2. Wagner Automatic Electrostatic Spray Guns

>>> Overview

>>> Key Features

>>> Advantages

>>> Limitations

>> 3. Nordson Automatic Electrostatic Spray Guns

>>> Overview

>>> Key Features

>>> Advantages

>>> Limitations

>> 4. ITW Gema Automatic Electrostatic Spray Guns

>>> Overview

>>> Key Features

>>> Advantages

>>> Limitations

>> 5. Anest Iwata Automatic Electrostatic Spray Guns

>>> Overview

>>> Key Features

>>> Advantages

>>> Limitations

● Cost-Benefit Analysis

>> Long-Term Savings

>> Environmental Impact

● Conclusion

>> Frequently Asked Questions

Automatic electrostatic spray guns have revolutionized the painting and coating industry by providing superior efficiency and finish quality. This article delves into the cost versus performance of the leading automatic electrostatic spray guns available today, helping you make an informed decision for your specific needs.

Understanding Electrostatic Spray Technology

What is Electrostatic Spray?

Electrostatic spray technology utilizes an electric charge to attract paint particles to the surface being coated. This method significantly enhances transfer efficiency, reducing overspray and waste. The result is a more uniform coating with less material used, making it an attractive option for various applications, from automotive to industrial coatings.

How Does It Work?

The process involves charging the paint particles as they exit the spray gun. The charged particles are then attracted to the grounded surface, ensuring that more paint adheres to the object rather than being lost in the air. This technology not only improves the quality of the finish but also minimizes the environmental impact by reducing volatile organic compounds (VOCs).

Key Factors in Cost vs Performance

When evaluating automatic electrostatic spray guns, several factors come into play that influence both cost and performance:

Initial Investment

The upfront cost of electrostatic spray guns is generally higher than that of conventional spray guns. However, this initial investment can be offset by the long-term savings achieved through reduced paint consumption and lower labor costs.

Transfer Efficiency

One of the most significant advantages of electrostatic spray guns is their high transfer efficiency, often exceeding 90%. This means that a larger percentage of the paint used actually adheres to the surface, resulting in less waste and lower material costs.

Maintenance and Durability

Automatic electrostatic spray guns are designed for durability and require less frequent maintenance compared to manual options. This reliability can lead to lower operational costs over time, as downtime for repairs and maintenance is minimized.

Versatility

Many modern electrostatic spray guns are versatile, capable of handling a variety of coatings, including waterborne and solvent-based paints. This adaptability can reduce the need for multiple types of equipment, further enhancing cost-effectiveness.

Top Automatic Electrostatic Spray Guns

1. 3M Automatic Electrostatic Spray Guns

Overview

3M is a leader in surface finishing technologies, known for its innovative solutions. Their automatic electrostatic spray guns are designed for high transfer efficiency and consistent atomization.

Key Features

- High transfer efficiency

- Robust construction

- User-friendly controls

Advantages

3M guns are praised for their reliability and performance, making them a favorite in the automotive and industrial sectors.

Limitations

The initial cost can be a barrier for smaller operations, but the ROI is often realized quickly through material savings.

2. Wagner Automatic Electrostatic Spray Guns

Overview

Wagner offers a range of automatic electrostatic spray guns that are well-regarded for their performance and ease of use.

Key Features

- Adjustable spray patterns

- Lightweight design

- Low maintenance requirements

Advantages

Wagner guns provide excellent customer support and are known for their consistent performance across various applications.

Limitations

Some users report a learning curve when configuring complex spray patterns, which may require additional training.

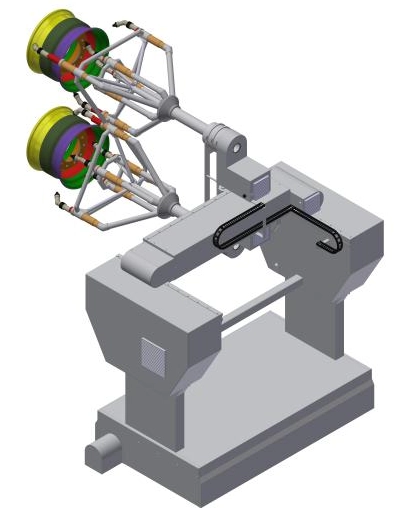

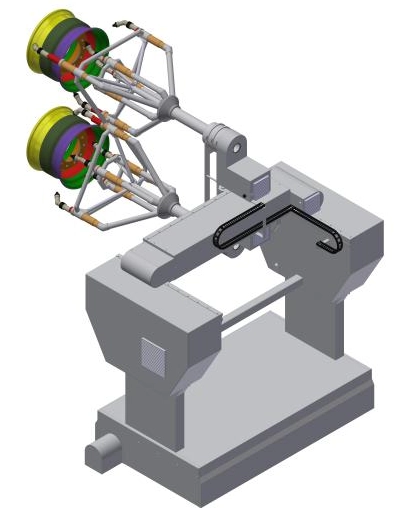

3. Nordson Automatic Electrostatic Spray Guns

Overview

Nordson is another prominent player in the electrostatic spray gun market, known for its advanced technology and high-quality products.

Key Features

- High voltage cascade for improved atomization

- Durable construction

- Integrated control systems

Advantages

Nordson guns are designed for high efficiency and are suitable for a wide range of applications, from automotive to industrial coatings.

Limitations

The complexity of the technology may require specialized training for operators.

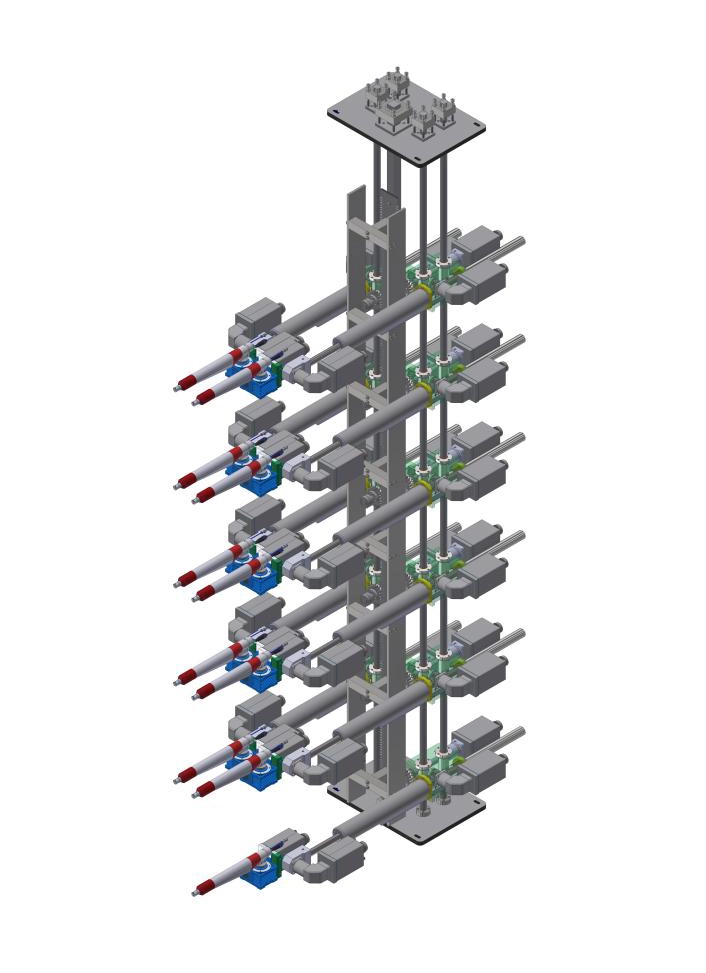

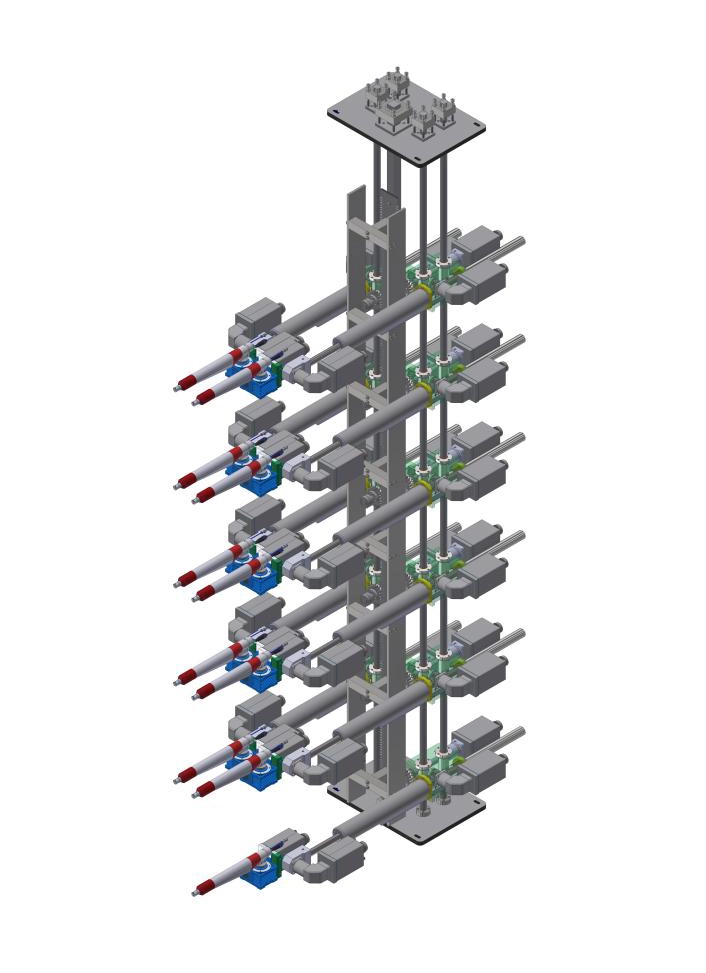

4. ITW Gema Automatic Electrostatic Spray Guns

Overview

ITW Gema specializes in powder coating technology and offers a range of electrostatic spray guns that excel in performance.

Key Features

- High transfer efficiency

- Modular design for easy maintenance

- Advanced control systems

Advantages

These guns are particularly effective for powder coatings, providing a high-quality finish with minimal waste.

Limitations

The initial investment can be significant, but the long-term savings often justify the cost.

5. Anest Iwata Automatic Electrostatic Spray Guns

Overview

Anest Iwata is known for its precision engineering and high-quality spray guns, including automatic electrostatic options.

Key Features

- Lightweight and ergonomic design

- High transfer efficiency

- Versatile application capabilities

Advantages

These guns are designed for ease of use and can handle a variety of coatings, making them suitable for diverse applications.

Limitations

While they offer excellent performance, the cost may be higher than some competitors.

Cost-Benefit Analysis

Long-Term Savings

While the initial cost of automatic electrostatic spray guns can be daunting, the long-term savings in material costs, labor, and maintenance can make them a wise investment. Companies often see a return on investment within a few months due to reduced paint usage and increased efficiency.

Environmental Impact

Using electrostatic spray guns can significantly reduce VOC emissions, contributing to a more sustainable operation. This not only benefits the environment but can also enhance a company's reputation and compliance with regulations.

Conclusion

Choosing the right automatic electrostatic spray gun involves weighing the initial costs against the long-term benefits. With their high transfer efficiency, reduced waste, and versatility, these guns can provide significant savings and improved quality in the long run. Brands like 3M, Wagner, Nordson, ITW Gema, and Anest Iwata offer a range of options to suit various needs and budgets.

Frequently Asked Questions

1. What is the main advantage of using electrostatic spray guns?

- The primary advantage is their high transfer efficiency, which reduces paint waste and improves finish quality.

2. Are electrostatic spray guns more expensive than conventional spray guns?

- Yes, they typically have a higher initial cost, but they can lead to significant savings over time.

3. Can electrostatic spray guns be used with all types of paint?

- Most modern electrostatic spray guns can handle a variety of coatings, including waterborne and solvent-based paints.

4. What maintenance is required for electrostatic spray guns?

- They generally require less maintenance than manual guns, but regular cleaning and occasional part replacements are necessary.

5. How quickly can I expect a return on investment with an electrostatic spray gun?

- Many users report a return on investment within a few months due to reduced material costs and increased efficiency.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.