Content Menu

● Understanding Multi-Color Powder Coating

>> What is Multi-Color Powder Coating?

>> Benefits of Multi-Color Powder Coating

● Key Features of Spray Gun Units for Multi-Color Powder Coating

>> Powder Feeding System

>> Spray Gun Design

>> Control Systems and Automation

● Types of Spray Gun Units Suitable for Multi-Color Powder Coating

>> Manual Spray Guns

>> Automatic Spray Guns

>> Hybrid Systems

● Factors to Consider When Choosing the Best Spray Gun Unit

>> Powder Compatibility

>> Substrate and Surface Geometry

>> Transfer Efficiency and Overspray Reduction

>> Maintenance and Durability

>> Cost and Return on Investment

● Steps to Implement Multi-Color Powder Coating with the Selected Unit

>> Pre-Installation Preparation

>> Installation and Commissioning

>> Production and Quality Control

● Troubleshooting Common Issues

>> Color Blending and Contamination

>> Uneven Coverage

>> Low Transfer Efficiency

>> Equipment Downtime

● Future Trends in Spray Gun Technology for Multi-Color Powder Coating

>> Smart Spray Guns with AI Integration

>> Enhanced Automation and Robotics

>> Eco-Friendly Innovations

● Frequently Asked Questions (FAQs)

>> What makes a spray gun suitable for multi-color powder coating?

>> How can cross-contamination between colors be minimized?

>> Is manual spraying viable for multi-color powder coating in production?

>> How important is electrostatic charging in powder coating?

>> What maintenance practices extend spray gun lifespan?

Multi-color powder coating is a sophisticated finishing process that enhances the aesthetic appeal and durability of various products. Selecting the right spray gun unit is essential to achieving high-quality, consistent results while optimizing efficiency and cost-effectiveness. This comprehensive guide explores all critical factors to consider when choosing the best spray gun for multi-color powder coating applications.

Understanding Multi-Color Powder Coating

What is Multi-Color Powder Coating?

Multi-color powder coating involves applying different colored powders sequentially or simultaneously onto a surface, resulting in vibrant, layered finishes that cannot be achieved through single-color powder coating. This technique is popular in decorative applications, automotive parts, consumer electronics, and custom furniture.

Benefits of Multi-Color Powder Coating

- Enhanced Visual Appeal: Offers complex, striking color combinations and patterns.

- Durability: Coatings are tough, resistant to corrosion, chemicals, and physical impact.

- Environmentally Friendly: Powder coatings emit negligible volatile organic compounds (VOCs).

- Efficiency: Enables precise control over the application of multiple colors with minimal waste.

Key Features of Spray Gun Units for Multi-Color Powder Coating

Selecting a spray gun unit requires understanding the technical capabilities and design elements that impact performance in multi-color powder coating.

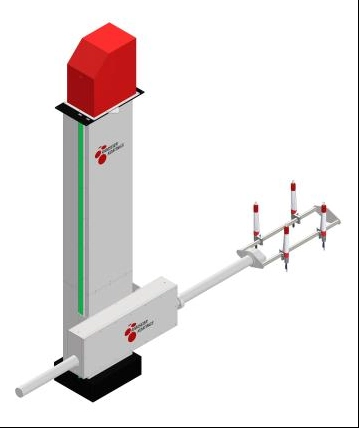

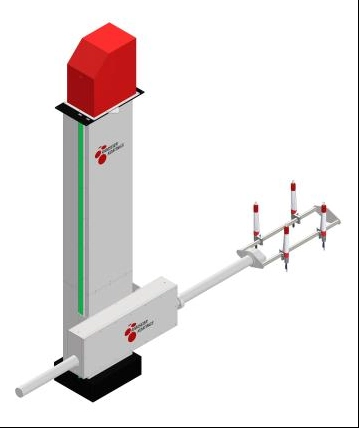

Powder Feeding System

A robust powder feeding system ensures smooth, continuous delivery of powder to the spray gun. Essential considerations include:

- Multiple Powder Hoppers: Must handle different colors separately to prevent cross-contamination.

- Stable Powder Flow Rate: Maintains consistent application thickness and finish quality.

- Easy Loading and Cleaning: Simplifies switching between colors and reduces downtime.

Spray Gun Design

The spray gun itself is a critical component that impacts the transfer efficiency and precision of each color applied.

- Electrostatic Charging: Essential for powder particles to adhere efficiently to grounded objects, improving transfer efficiency.

- Adjustable Voltage: Allows fine-tuning to different powders and substrates.

- Nozzle Options: Interchangeable nozzles accommodate various spray patterns and flow rates.

- Lightweight and Ergonomic Build: Reduces operator fatigue during extended use.

Control Systems and Automation

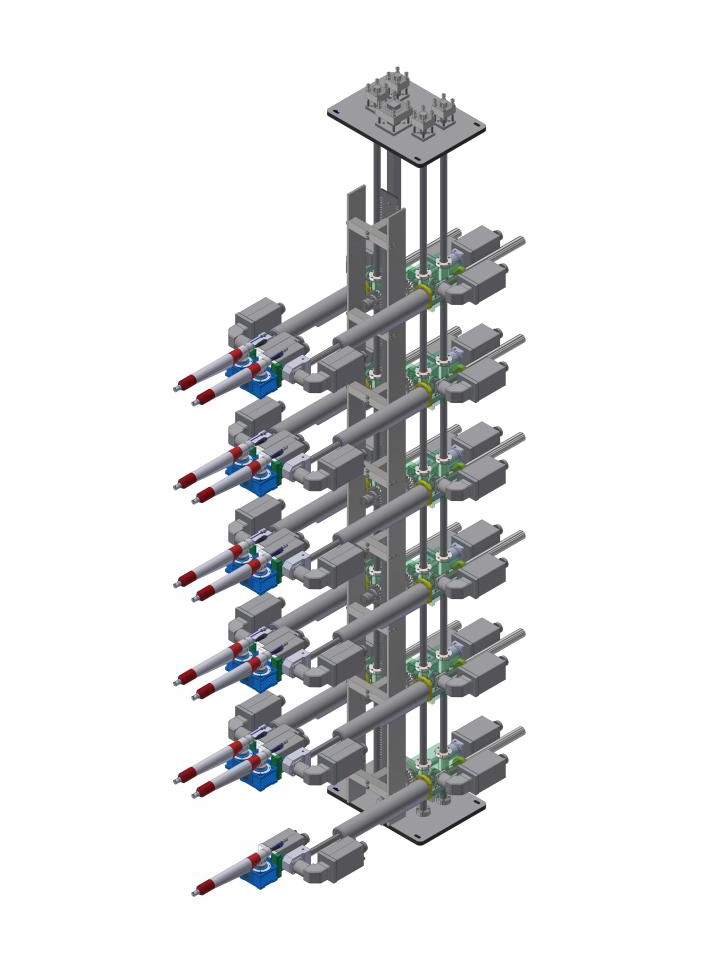

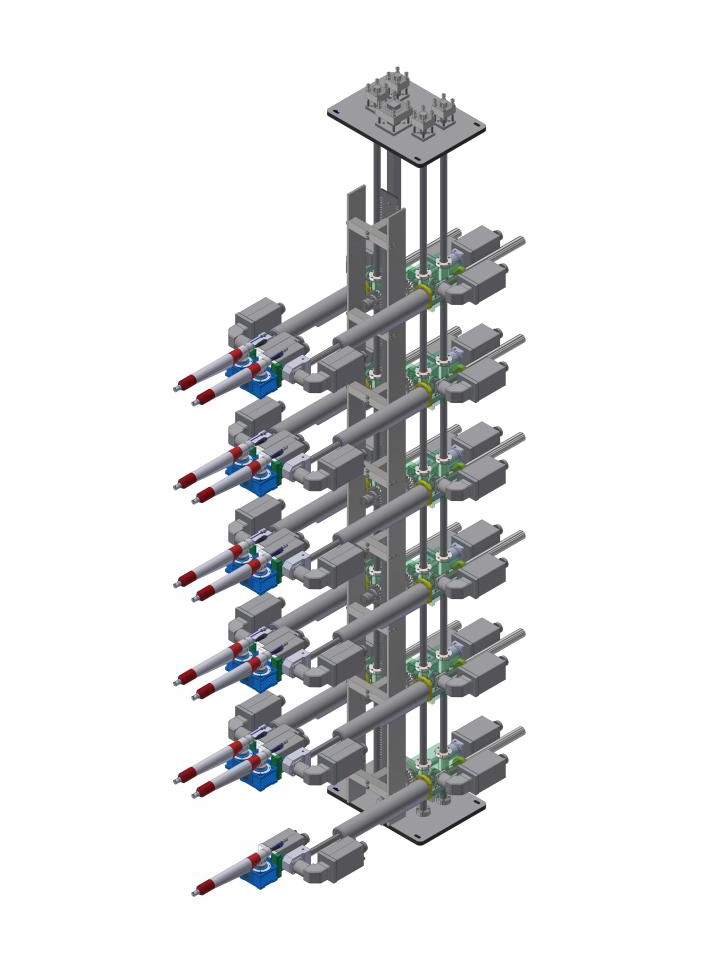

Advanced spray gun units incorporate sophisticated control systems to enhance multi-color applications.

- Programmable Controllers: Set and automate color change sequences with precise timing.

- Color Switching Mechanisms: Minimize contamination and enable sharp color separations.

- Integration with Robotic Arms: Improves repeatability and handling of complex shapes.

- Real-Time Monitoring: Tracks powder flow, voltage, and coverage for quality assurance.

Types of Spray Gun Units Suitable for Multi-Color Powder Coating

Manual Spray Guns

Manual units are favored for small-scale or prototype work where flexibility and operator skill are paramount.

- Advantages: Low cost, easy setup, and direct control.

- Limitations: Slower application for multiple colors, operator-dependent quality, increased risk of color blending.

Automatic Spray Guns

Automatic guns are integral for mass production environments requiring consistency and speed.

- Advantages: Precise control over multiple colors, faster cycle times, less operator dependency.

- Limitations: Higher initial investment, requires programming and maintenance.

Hybrid Systems

Hybrid spray gun units combine manual and automatic elements to accommodate diverse production needs.

- Advantages: Flexibility to operate in different modes, adjustable for batch sizes.

- Limitations: May involve complex controls and calibration.

Factors to Consider When Choosing the Best Spray Gun Unit

Powder Compatibility

Not all guns are suitable for every type of powder. Consider:

- Particle Size: The equipment must accommodate the powder size range.

- Material Type: Some powders have special handling requirements such as metal powders versus polymer-based powders.

- Color Complexity: More intricate powder types may require enhanced control precision.

Substrate and Surface Geometry

The shape and material of the parts being coated affect the choice of spray gun.

- Flat vs. Complex Surfaces: Guns with adjustable nozzles or robotic integration help achieve uniform coverage.

- Conductive vs. Non-Conductive: Electrostatic charging efficiency depends on substrate conductivity.

Transfer Efficiency and Overspray Reduction

Higher transfer efficiency reduces powder waste and environmental impact.

- Look for guns offering precise electrostatic charging and powder flow control.

- Minimizing overspray lowers cleanup time and costs.

Maintenance and Durability

Powder coating environments can be harsh; equipment should be robust.

- Choose units with easy disassembly for cleaning.

- Durable materials resist corrosion and abrasion.

- Availability of spare parts and service support is crucial.

Cost and Return on Investment

Consider not just upfront costs but also operational expenses.

- Evaluate powder consumption rates and energy use.

- Factor in labor costs based on ergonomics and automation level.

- Assess potential for improved product quality and reduced rework.

Steps to Implement Multi-Color Powder Coating with the Selected Unit

Pre-Installation Preparation

- Define Production Goals: Determine batch sizes, color combinations, and throughput.

- Assess Plant Environment: Check for ventilation, powder recovery systems, and workspace layout.

Installation and Commissioning

- Set up the powder feeding systems with appropriate hoppers for each color.

- Calibrate spray guns for powder type, voltage, and spray pattern.

- Train operators and technicians on handling and maintenance.

Production and Quality Control

- Monitor powder feed rates, cross-contamination, and color transitions.

- Perform regular inspections of coating thickness and adhesion.

- Adjust parameters based on feedback for continuous improvement.

Troubleshooting Common Issues

Color Blending and Contamination

- Ensure separate powder lines are thoroughly cleaned between colors.

- Use purging sequences to clear residual powder.

Uneven Coverage

- Adjust spray parameters such as voltage, powder flow rate, and gun distance.

- Check for clogs or worn nozzles.

Low Transfer Efficiency

- Improve grounding and ensure proper electrostatic settings.

- Inspect gun components for damage affecting charging.

Equipment Downtime

- Maintain regular cleaning schedules.

- Stock critical replacement parts to minimize repair delays.

Future Trends in Spray Gun Technology for Multi-Color Powder Coating

Smart Spray Guns with AI Integration

Emerging guns leverage artificial intelligence to optimize coating parameters dynamically.

Enhanced Automation and Robotics

Greater integration with robotic systems improves precision and repeatability.

Eco-Friendly Innovations

Development focuses on powders and guns that reduce waste and energy consumption further.

Frequently Asked Questions (FAQs)

What makes a spray gun suitable for multi-color powder coating?

A suitable spray gun must support multiple powder hoppers, allow rapid color changes with minimal contamination, provide adjustable electrostatic charging, and feature precise control to handle different powder types effectively.

How can cross-contamination between colors be minimized?

Using separate, dedicated powder feed lines for each color, performing thorough cleaning between runs, and employing automated purging systems during color changes are effective ways to reduce cross-contamination.

Is manual spraying viable for multi-color powder coating in production?

While manual spraying offers flexibility for small batches or prototypes, it is generally less efficient and consistent than automated systems, especially for complex or high-volume multi-color jobs.

How important is electrostatic charging in powder coating?

Electrostatic charging is crucial as it increases transfer efficiency by attracting charged powder particles to grounded parts, reducing powder waste and improving coating quality.

What maintenance practices extend spray gun lifespan?

Regular cleaning, inspection of nozzles and electrodes, timely replacement of worn parts, and proper storage when not in use all help maintain spray gun functionality and lifespan.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.