Content Menu

● Understanding Electrostatic Spray Technology

>> What is Electrostatic Spray Painting?

>> How Does It Work?

● Advantages of Manual Electrostatic Spray Guns

>> Increased Transfer Efficiency

>> Reduced Overspray and Waste

>> Improved Finish Quality

>> Versatility in Coating Applications

● Applications of Manual Electrostatic Spray Guns

>> Automotive Industry

>> Furniture and Woodworking

>> Industrial Coatings

>> Custom Coating Jobs

● Best Practices for Using Manual Electrostatic Spray Guns

>> Proper Setup and Maintenance

>> Training Operators

>> Environmental Considerations

● Conclusion

>> Frequently Asked Questions

In the world of custom coating jobs, efficiency and precision are paramount. Manual electrostatic spray guns have emerged as a game-changer in this field, offering significant advantages over traditional spray methods. This article delves into the workings, benefits, and applications of manual electrostatic spray guns, highlighting how they can enhance productivity and quality in custom coating jobs.

Understanding Electrostatic Spray Technology

What is Electrostatic Spray Painting?

Electrostatic spray painting is a process that uses an electric charge to attract paint particles to a surface. This method significantly improves transfer efficiency, meaning more paint adheres to the intended surface while reducing overspray. The basic principle involves charging the paint particles as they exit the spray gun, which are then attracted to the grounded object being coated.

How Does It Work?

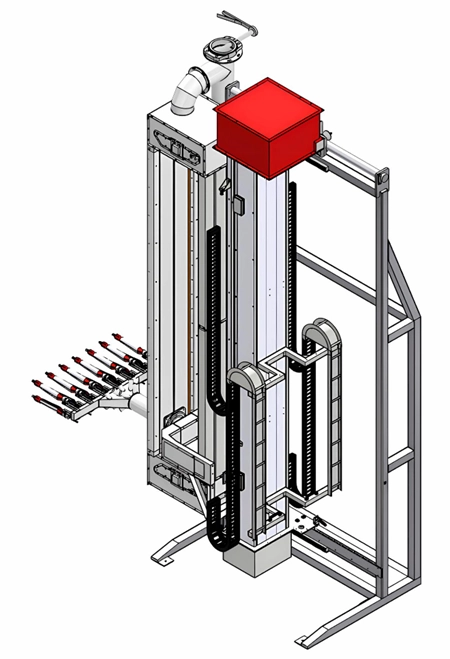

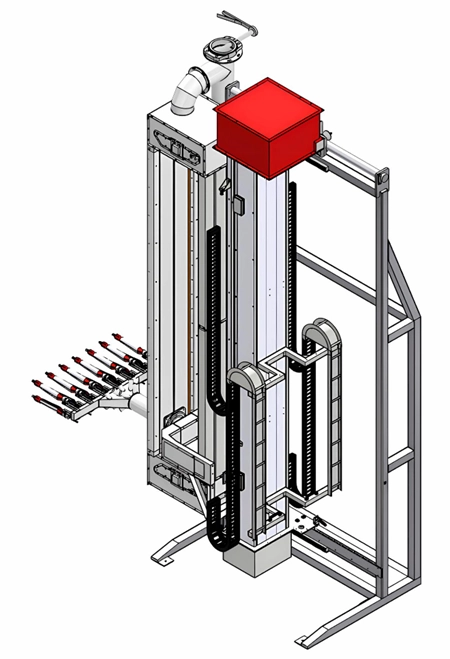

The operation of an electrostatic spray gun involves several key components:

1. Power Supply: This generates a high voltage (typically between 40 kV to 100 kV) that charges the paint particles.

2. Spray Gun: The gun atomizes the paint into fine droplets, which are then charged as they pass through the nozzle.

3. Grounded Object: The object being coated is grounded, creating a magnetic-like attraction between the charged paint and the surface.

This process not only enhances the efficiency of paint application but also ensures a more uniform coating.

Advantages of Manual Electrostatic Spray Guns

Increased Transfer Efficiency

One of the most significant benefits of using manual electrostatic spray guns is their high transfer efficiency. Traditional spray methods often result in a considerable amount of paint being wasted due to overspray. In contrast, electrostatic guns can achieve transfer efficiencies of up to 90% or more, meaning that nearly all the paint applied ends up on the surface.

Reduced Overspray and Waste

With the electrostatic attraction, paint particles are drawn to the surface, minimizing overspray. This not only conserves materials but also reduces the need for extensive cleanup after the coating process. The reduction in waste translates to cost savings, making electrostatic spray guns a more economical choice for businesses.

Improved Finish Quality

The electrostatic process allows for a more even application of paint, resulting in a smoother finish. This is particularly important in custom coating jobs where aesthetics are crucial. The ability to achieve a consistent layer of paint enhances the overall quality of the finished product.

Versatility in Coating Applications

Manual electrostatic spray guns are versatile and can be used with various types of coatings, including waterborne, solvent-based, and specialty paints. This adaptability makes them suitable for a wide range of industries, from automotive to furniture manufacturing.

Applications of Manual Electrostatic Spray Guns

Automotive Industry

In the automotive sector, manual electrostatic spray guns are used for painting car bodies and parts. The high transfer efficiency and quality finish are essential for meeting industry standards and customer expectations. Additionally, the reduced waste helps manufacturers lower their operational costs.

Furniture and Woodworking

The furniture industry benefits from the precision and quality that electrostatic spray guns provide. Whether applying a clear coat or a colored finish, these guns ensure that every piece is coated evenly, enhancing the product's durability and appearance.

Industrial Coatings

Manual electrostatic spray guns are also widely used in industrial applications, such as coating machinery and equipment. The ability to apply a thick, even layer of paint helps protect against corrosion and wear, extending the lifespan of industrial assets.

Custom Coating Jobs

For businesses that specialize in custom coatings, the flexibility of manual electrostatic spray guns allows for tailored solutions. Whether it's a unique color or finish, these guns can adapt to various requirements, ensuring customer satisfaction.

Best Practices for Using Manual Electrostatic Spray Guns

Proper Setup and Maintenance

To maximize the efficiency of manual electrostatic spray guns, proper setup and maintenance are crucial. This includes ensuring that the power supply is correctly calibrated and that the spray gun is clean and free of clogs. Regular maintenance checks can prevent issues that may affect performance.

Training Operators

Operators should be trained in the specific techniques required for using electrostatic spray guns. Understanding how to adjust settings for different materials and conditions can significantly impact the quality of the finish and the efficiency of the application.

Environmental Considerations

When using electrostatic spray guns, it's essential to consider environmental factors. Proper ventilation is necessary to manage fumes and ensure a safe working environment. Additionally, using low-VOC (volatile organic compounds) paints can further reduce environmental impact.

Conclusion

Manual electrostatic spray guns represent a significant advancement in the field of custom coating jobs. Their ability to boost efficiency, reduce waste, and improve finish quality makes them an invaluable tool for various industries. By adopting this technology, businesses can enhance their productivity and deliver superior results to their customers.

Frequently Asked Questions

1. What is the main advantage of using electrostatic spray guns?

- The main advantage is their high transfer efficiency, which reduces paint waste and improves coating quality.

2. Can electrostatic spray guns be used with all types of paint?

- Yes, they can be used with a variety of coatings, including waterborne, solvent-based, and specialty paints.

3. How do I maintain my electrostatic spray gun?

- Regular cleaning, checking for clogs, and ensuring proper calibration of the power supply are essential for maintenance.

4. What industries benefit the most from electrostatic spray technology?

- Industries such as automotive, furniture manufacturing, and industrial coatings benefit significantly from this technology.

5. Is training necessary for operators using electrostatic spray guns?

- Yes, training is crucial to ensure operators understand how to use the equipment effectively and safely.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.