Content Menu

● Understanding Spray Gun Technology

>> What is a Spray Gun?

>> Types of Spray Guns

● Key Features to Look for in a Spray Gun Unit

>> Transfer Efficiency

>> Adjustability

>> Durability

>> Ease of Cleaning

>> Compatibility with Coatings

● Top Spray Gun Units for High-Throughput Manufacturing

>> 1. 3M Performance Spray Gun

>> 2. Graco XTR 7+ Airless Spray Gun

>> 3. DeVilbiss JGA Spray Gun

>> 4. Wagner GM 4700AC AirCoat Spray Gun

>> 5. Binks 2100 Conventional Spray Gun

● Choosing the Right Spray Gun for Your Needs

>> Assess Your Production Requirements

>> Evaluate Your Budget

>> Test Before You Buy

● Maintenance Tips for Spray Guns

>> Regular Cleaning

>> Inspect for Wear

>> Store Properly

● Conclusion

>> Frequently Asked Questions

In the fast-paced world of manufacturing, efficiency and quality are paramount. One of the critical tools that can significantly impact both is the spray gun unit. This article explores the best spray gun units for high-throughput manufacturing lines, focusing on their features, benefits, and how to choose the right one for your needs.

Understanding Spray Gun Technology

What is a Spray Gun?

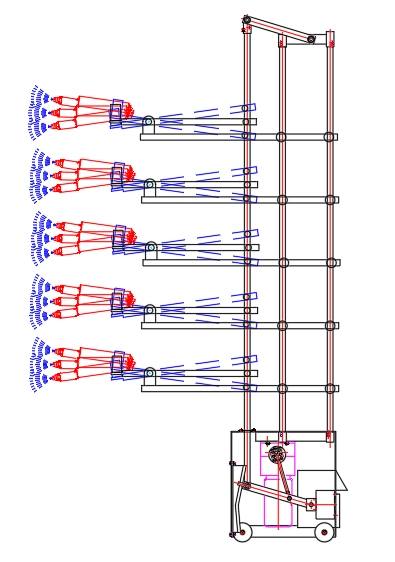

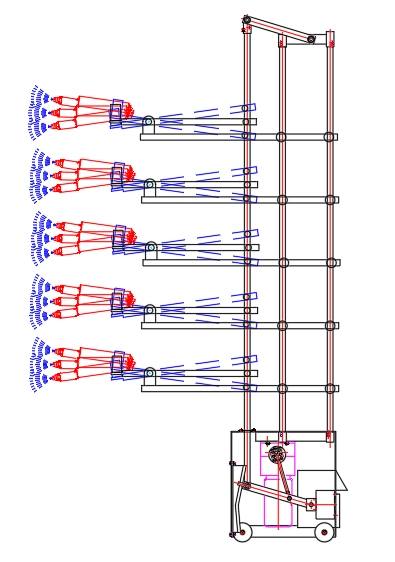

A spray gun is a device that atomizes liquid coatings, allowing for an even application on various surfaces. These guns are essential in industries such as automotive, aerospace, and furniture manufacturing, where high-quality finishes are required.

Types of Spray Guns

1. Airless Spray Guns: These guns use high pressure to force paint through a nozzle, creating a fine mist. They are ideal for large surfaces and can handle thicker materials.

2. HVLP (High Volume Low Pressure) Spray Guns: These guns use a high volume of air at low pressure, reducing overspray and improving transfer efficiency. They are perfect for detailed work and provide a smooth finish.

3. Electrostatic Spray Guns: These guns charge the paint particles, allowing them to adhere better to the surface. This technology is particularly useful for metal surfaces and can significantly reduce waste.

4. Conventional Spray Guns: These are the traditional spray guns that use compressed air to atomize the paint. They are versatile but can produce more overspray compared to HVLP and airless options.

Key Features to Look for in a Spray Gun Unit

Transfer Efficiency

Transfer efficiency refers to the amount of paint that actually adheres to the surface compared to what is wasted in overspray. High transfer efficiency means less paint is wasted, which is crucial for cost savings in high-throughput environments.

Adjustability

The ability to adjust the spray pattern, fluid flow, and air pressure is vital for achieving the desired finish. Look for guns that offer easy adjustments to accommodate different materials and applications.

Durability

In a manufacturing setting, equipment must withstand rigorous use. Choose spray guns made from high-quality materials that can endure wear and tear over time.

Ease of Cleaning

A spray gun that is easy to disassemble and clean will save time and reduce downtime in production. Look for models that allow for quick maintenance.

Compatibility with Coatings

Ensure that the spray gun is compatible with the types of coatings you plan to use, whether they are water-based, solvent-based, or specialty coatings.

Top Spray Gun Units for High-Throughput Manufacturing

1. 3M Performance Spray Gun

The 3M Performance Spray Gun is designed for high efficiency and precision. It features a lightweight design and is compatible with the 3M PPS™ Series 2.0 Spray Cups, allowing for quick color changes and reduced waste. Its high transfer efficiency makes it ideal for automotive and industrial applications.

2. Graco XTR 7+ Airless Spray Gun

The Graco XTR 7+ is known for its high pressure and versatility. It can handle a wide range of coatings, making it suitable for various manufacturing processes. Its ergonomic design reduces fatigue, and the easy-to-clean filter system enhances maintenance efficiency.

3. DeVilbiss JGA Spray Gun

The DeVilbiss JGA is a conventional spray gun that offers excellent atomization and control. It is particularly effective for detailed work and provides a smooth finish. Its durable construction ensures longevity in demanding environments.

4. Wagner GM 4700AC AirCoat Spray Gun

This air-assisted airless spray gun combines the benefits of airless and conventional spraying. It provides a fine finish with reduced overspray, making it suitable for high-quality applications in furniture and automotive industries.

5. Binks 2100 Conventional Spray Gun

The Binks 2100 is a reliable choice for those needing a conventional spray gun. It offers excellent control and is suitable for a variety of coatings. Its robust design ensures it can withstand the rigors of high-throughput manufacturing.

Choosing the Right Spray Gun for Your Needs

Assess Your Production Requirements

Consider the volume of production and the types of coatings you will be using. High-throughput lines may benefit from airless or HVLP guns for speed and efficiency.

Evaluate Your Budget

While investing in high-quality spray guns can be costly, consider the long-term savings from reduced paint waste and improved efficiency. Balance your budget with the features that are most important for your operations.

Test Before You Buy

If possible, test different spray guns to see which one feels comfortable and meets your performance expectations. Many manufacturers offer demos or trial periods.

Maintenance Tips for Spray Guns

Regular Cleaning

Clean your spray gun after each use to prevent clogs and ensure optimal performance. Follow the manufacturer's instructions for disassembly and cleaning.

Inspect for Wear

Regularly check for signs of wear, especially on nozzles and seals. Replacing worn parts promptly can prevent larger issues down the line.

Store Properly

Store your spray gun in a clean, dry place to protect it from damage. Consider using a protective case to prevent accidental drops or impacts.

Conclusion

Choosing the best spray gun unit for high-throughput manufacturing lines involves understanding the technology, assessing your needs, and considering the features that will enhance your production efficiency. With the right equipment, you can achieve high-quality finishes while minimizing waste and maximizing productivity.

Frequently Asked Questions

1. What is the difference between HVLP and airless spray guns?

HVLP guns use high volume and low pressure to minimize overspray, while airless guns use high pressure to atomize paint, making them suitable for larger surfaces.

2. How do I maintain my spray gun?

Regular cleaning after each use, inspecting for wear, and proper storage are essential for maintaining your spray gun.

3. What is transfer efficiency?

Transfer efficiency is the percentage of paint that adheres to the surface compared to what is lost in overspray.

4. Can I use water-based paints with all spray guns?

Not all spray guns are compatible with water-based paints. Check the manufacturer's specifications to ensure compatibility.

5. What should I consider when choosing a spray gun?

Consider factors such as transfer efficiency, adjustability, durability, ease of cleaning, and compatibility with coatings.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.