Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> Importance of Proper Operation

● Selecting the Right Equipment

>> Material Selection

>> Design Considerations

>> Sieve Size and Mesh Type

● Implementing Effective Dust Control Measures

>> Enclosed Systems

>> Local Exhaust Ventilation

● Optimizing Sieving Processes

>> Adjusting Operating Parameters

>> Monitoring Performance

● Maintenance Best Practices

>> Regular Cleaning

>> Lubrication

>> Record Keeping

● Safety Measures

>> Personal Protective Equipment (PPE)

>> Emergency Procedures

>> Equipment Installation

● Conclusion

>> Frequently Asked Questions

Vibrating sieves are essential tools in powder processing, widely used across various industries to ensure the quality and consistency of powdered materials. Proper operation of these machines not only enhances efficiency but also prolongs their lifespan. This article outlines best practices for operating a vibrating sieve, focusing on equipment selection, maintenance, operational techniques, and safety measures.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

A vibrating sieve is a mechanical device that uses vibration to separate materials based on size. It consists of a screen or mesh that allows smaller particles to pass through while retaining larger ones. This process is crucial in industries such as food processing, pharmaceuticals, and chemicals, where particle size can significantly affect product quality.

Importance of Proper Operation

Operating a vibrating sieve correctly is vital for several reasons:

- Quality Control: Ensures uniform particle size, which is critical for product consistency.

- Efficiency: Reduces downtime and increases throughput.

- Equipment Longevity: Proper use and maintenance can extend the life of the sieve.

Selecting the Right Equipment

Material Selection

Choosing the right material for the sieve is crucial. Stainless steel is often preferred due to its durability, resistance to corrosion, and ease of cleaning. For specific applications, consider materials that can withstand the chemical properties of the powders being processed.

Design Considerations

Different designs of vibrating sieves cater to various applications:

- Rotary Vibrating Sieves: Ideal for fine powders and granules.

- Linear Vibrating Sieves: Best for dry powders, providing a horizontal screen surface.

- Electromagnetic Vibrating Sieves: Suitable for precise and high-frequency sieving, particularly for fine powders.

Sieve Size and Mesh Type

Selecting the appropriate mesh size is critical. A finer mesh is necessary for smaller particles, while a coarser mesh is suitable for larger materials. Additionally, consider using anti-blinding devices, such as rubber balls or ultrasonic units, to prevent clogging.

Implementing Effective Dust Control Measures

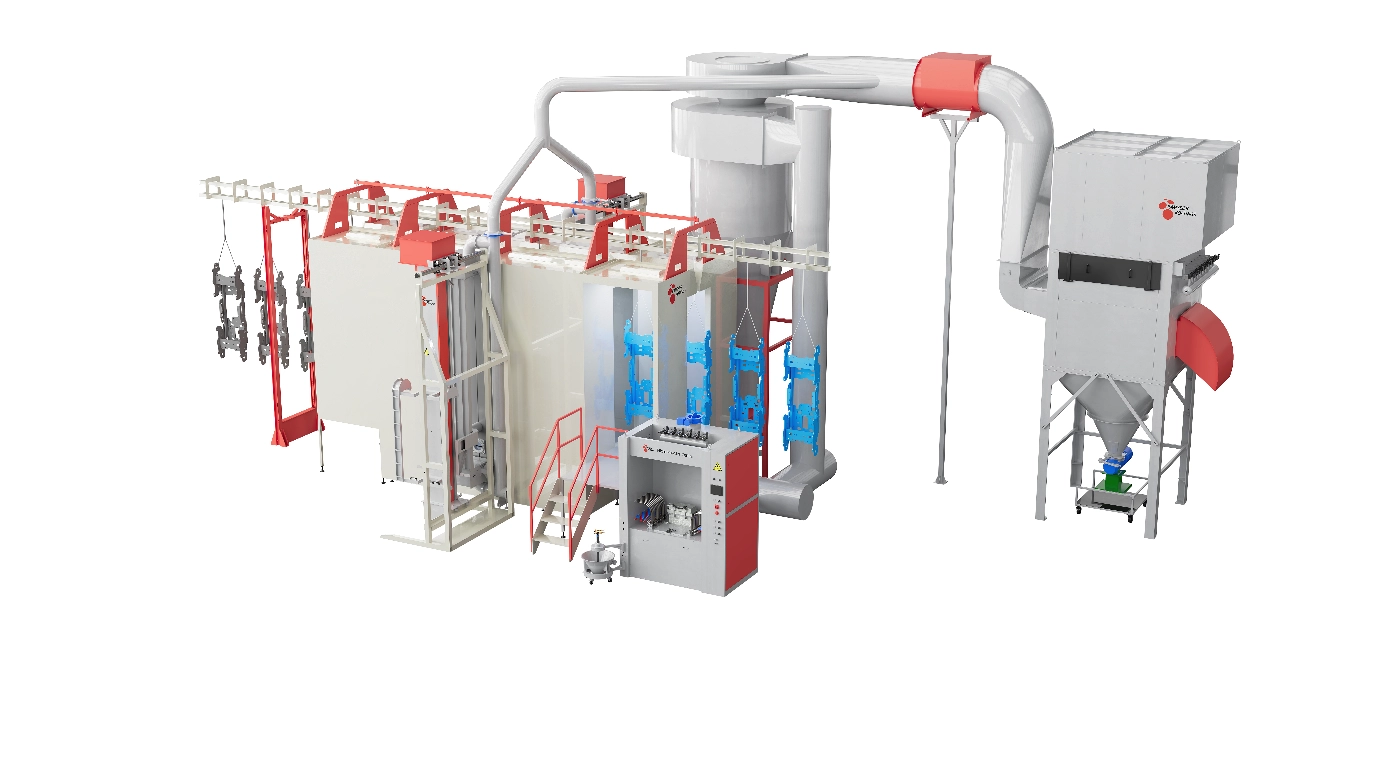

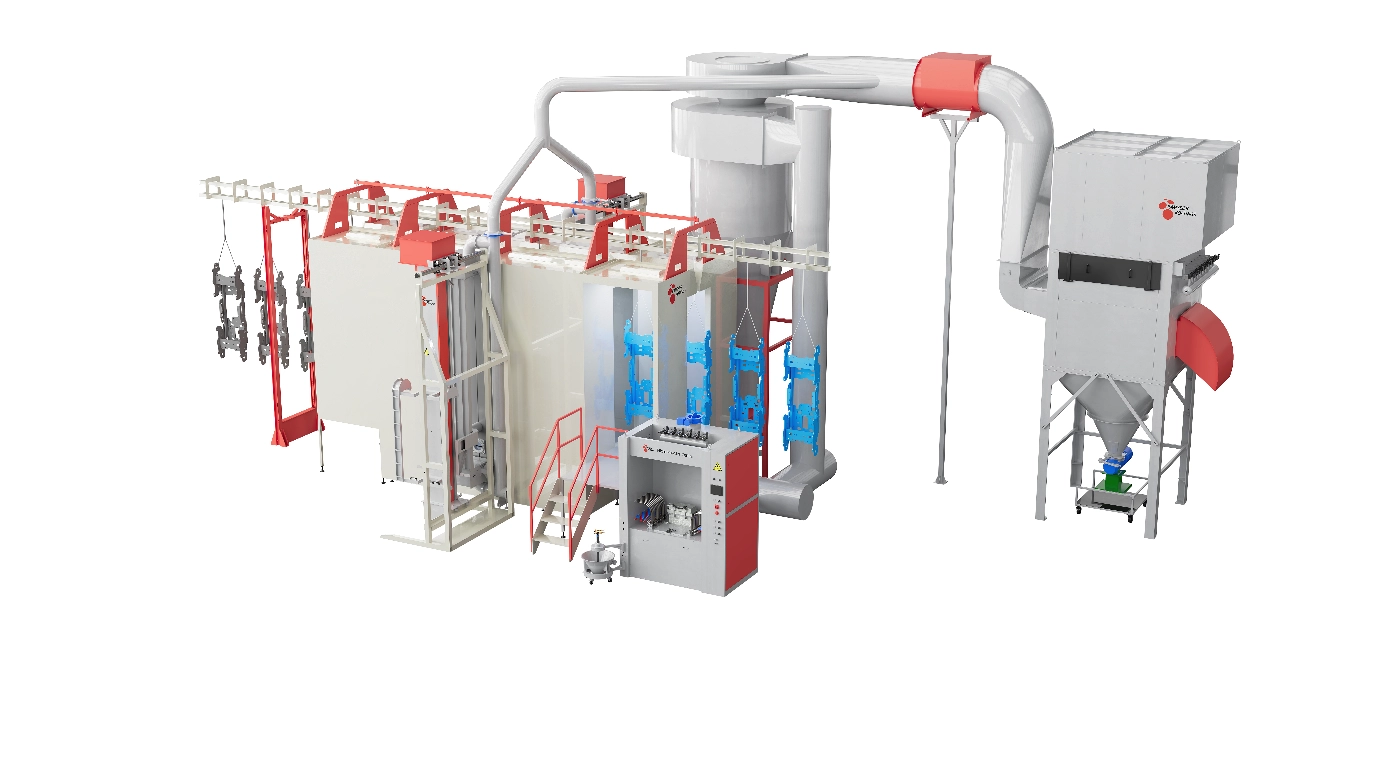

Enclosed Systems

To minimize dust exposure and maintain a clean working environment, use enclosed vibrating sieve systems. These systems help contain dust and prevent contamination of the surrounding area.

Local Exhaust Ventilation

Incorporating local exhaust ventilation systems can effectively capture airborne particles generated during the sieving process. This not only protects workers but also ensures compliance with health and safety regulations.

Optimizing Sieving Processes

Adjusting Operating Parameters

The efficiency of a vibrating sieve can be significantly affected by its operating parameters. Key factors include:

- Vibration Frequency: Adjusting the frequency can optimize the separation process. Higher frequencies may be suitable for fine powders, while lower frequencies can be effective for larger particles.

- Amplitude: The amplitude of vibration should be adjusted based on the material characteristics. A higher amplitude may be necessary for heavier materials.

Monitoring Performance

Regularly monitor the performance of the vibrating sieve. Check for signs of wear and tear, and ensure that the vibration levels are appropriate for the materials being processed. Implementing a routine inspection schedule can help identify issues before they lead to significant downtime.

Maintenance Best Practices

Regular Cleaning

Keeping the sieve clean is essential for maintaining its performance. Establish a cleaning schedule that includes:

- Daily Cleaning: Remove any residual powder after each use.

- Deep Cleaning: Conduct thorough cleaning at regular intervals to prevent contamination and buildup.

Lubrication

Proper lubrication of moving parts is crucial for smooth operation. Follow the manufacturer's guidelines for lubrication intervals and types of lubricants to use.

Record Keeping

Maintain a log of maintenance activities, including inspections, repairs, and cleaning. This documentation can help track the sieve's performance over time and identify patterns that may indicate underlying issues.

Safety Measures

Personal Protective Equipment (PPE)

Ensure that all operators wear appropriate PPE, including masks, gloves, and goggles, to protect against dust exposure. Training employees on the importance of PPE can enhance workplace safety.

Emergency Procedures

Establish clear emergency procedures in case of equipment failure or accidents. Regularly train staff on these procedures to ensure a quick and effective response.

Equipment Installation

Proper installation of the vibrating sieve is critical for safe operation. Ensure that the equipment is securely mounted and that all components are correctly aligned to prevent accidents.

Conclusion

Operating a vibrating sieve effectively requires a combination of proper equipment selection, regular maintenance, and adherence to safety protocols. By following these best practices, industries can enhance the efficiency of their powder processing operations, ensuring high-quality products and a safe working environment.

Frequently Asked Questions

1. What types of powders can vibrating sieves handle?

- Vibrating sieves can process a wide range of powders, including food-grade flours, spices, pharmaceuticals, and chemical powders.

2. How do I prevent screen clogging in powder sieving?

- Use sieves with ultrasonic or ball cleaning systems, select appropriate vibration frequency, and consider mesh materials designed to reduce blinding.

3. Can vibrating sieves handle wet powders?

- Yes, but it is essential to choose a sieve designed for wet materials, as they may require different operating parameters.

4. What maintenance is required for vibrating sieves?

- Regular cleaning, lubrication of moving parts, and routine inspections are necessary to maintain optimal performance.

5. How can I ensure the safety of operators when using vibrating sieves?

- Provide appropriate PPE, establish emergency procedures, and ensure proper installation and maintenance of the equipment.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.