Content Menu

● Understanding Electrostatic Spray Guns

>> What Is an Electrostatic Spray Gun?

>> Benefits for Small to Medium Enterprises

● Criteria for Selecting Budget Electrostatic Spray Guns

>> Performance and Transfer Efficiency

>> Compatibility with Paint Types

>> Ease of Use and Maintenance

>> Durability and Build Quality

>> Price and Warranty

● Top Budget Electrostatic Spray Guns for SMEs

>> Wagner FinishPro 130 HVLP

>> TCP Global HVLP Electrostatic Spray Gun

>> Earlex HV5500 Electrostatic Spray System

>> Garmat Electrostatic Spray Gun

>> Campbell Hausfeld SAG5000 Electrostatic Sprayer

● How to Maximize the Use of Budget Electrostatic Spray Guns

>> Proper Setup and Grounding

>> Paint Preparation and Filtering

>> Regular Cleaning and Maintenance

>> Operator Training

● Common Challenges and Solutions

>> Uneven Coating or Poor Adhesion

>> Excessive Overspray

>> Nozzle Clogging

>> Paint Compatibility Issues

● Frequently Asked Questions (FAQ)

Electrostatic spray guns have become indispensable tools for many small to medium enterprises (SMEs) involved in painting and coating. These devices enable efficient, uniform, and cost-effective application of paints and finishes, reducing waste and enhancing quality. However, finding an affordable, reliable electrostatic spray gun suitable for SMEs can be challenging due to the wide variety of products on the market and their varying features. This article offers a deep dive into the best budget electrostatic spray guns, helping SMEs make informed purchasing decisions without compromising quality and performance.

Understanding Electrostatic Spray Guns

What Is an Electrostatic Spray Gun?

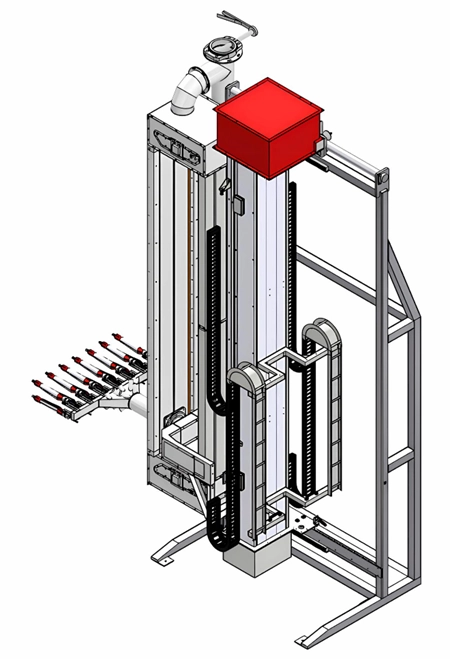

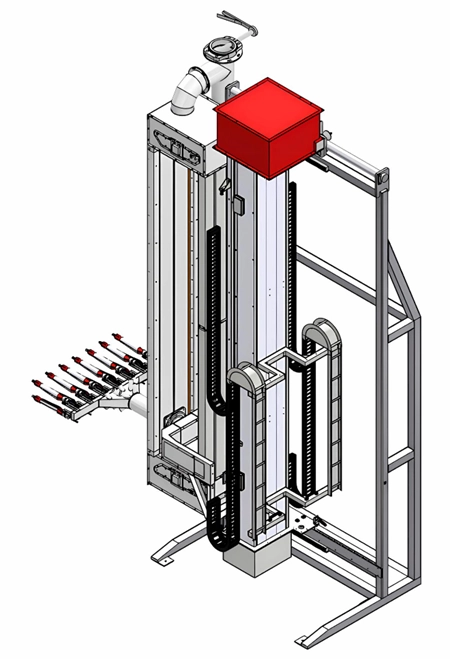

An electrostatic spray gun works by applying an electrostatic charge to the paint particles as they exit the nozzle. These charged particles are attracted to the grounded workpiece, resulting in superior coverage and minimal overspray. This technology increases transfer efficiency and reduces paint consumption compared to traditional spray guns.

Benefits for Small to Medium Enterprises

For SMEs, adopting electrostatic spray guns brings several benefits:

- Cost Savings: Reduced paint wastage lowers material costs.

- Improved Finish Quality: Enhanced paint adhesion results in smoother and more consistent surfaces.

- Increased Productivity: Faster application rates help meet production deadlines.

- Environmental Compliance: Lower volatile organic compounds (VOC) emissions support eco-friendly practices.

Criteria for Selecting Budget Electrostatic Spray Guns

When choosing electrostatic spray guns on a budget, SMEs should consider several important factors:

Performance and Transfer Efficiency

The primary purpose is to achieve excellent paint transfer rates. Higher efficiency means less paint is wasted, which directly influences running costs.

Compatibility with Paint Types

Verify compatibility with various coatings including water-based, solvent-based, and powder coatings to suit different projects.

Ease of Use and Maintenance

User-friendly designs with simple controls and straightforward cleaning procedures reduce downtime and training costs.

Durability and Build Quality

Even budget models should offer robust construction to withstand industrial environments and frequent use.

Price and Warranty

Ensure the purchase price aligns with the budget while the warranty offers reasonable protection against defects.

Top Budget Electrostatic Spray Guns for SMEs

Wagner FinishPro 130 HVLP

The Wagner FinishPro 130 HVLP spray gun is famous for its affordability and reliability. It supports electrostatic spraying with excellent atomization of water and solvent-based paints.

- Transfer efficiency reaches up to 80%, minimizing overspray.

- Lightweight and ergonomic design ease long-duration use.

- Quick-clean features help reduce production downtime.

- Ideal for wood, metal, and plastic applications.

TCP Global HVLP Electrostatic Spray Gun

TCP Global offers a quality electrostatic spray gun optimized for budget-conscious SMEs.

- Electrostatic charging improves paint coverage and reduces waste.

- Adjustable spray patterns enable versatile finishing options.

- Compatible with most commercial coatings.

- Robust stainless steel construction ensures durability.

- Suitable for automotive and industrial coatings.

Earlex HV5500 Electrostatic Spray System

The Earlex HV5500 is a compact electrostatic system designed for smaller operations with budget constraints.

- Affordable HVLP spray gun with electrostatic ionizer for enhanced coating transfer.

- Lightweight and portable for flexible application.

- Transparent paint cup allows easy monitoring.

- Ideal for furniture refinishing, cabinetry, and small machine parts.

Garmat Electrostatic Spray Gun

The Garmat spray gun provides an industrial-grade option at a lower cost compared to premium models.

- Offers adjustable charging voltage for precise control.

- Durable aluminum body with corrosion-resistant components.

- High-performance nozzle delivers fine atomization.

- Suitable for metal fabrication and equipment coatings.

- Easy maintenance extends lifespan.

Campbell Hausfeld SAG5000 Electrostatic Sprayer

The Campbell Hausfeld SAG5000 is a popular choice among SMEs for its balance of affordability and reliability.

- HVLP technology with electrostatic charging for efficient transfer.

- Variable flow control adjusts for different project requirements.

- Comes with multiple nozzles for varied spray patterns.

- Compact design optimal for workshops and smaller settings.

How to Maximize the Use of Budget Electrostatic Spray Guns

Proper Setup and Grounding

Ensuring proper grounding of the workpiece and spray gun is essential for effective electrostatic attraction and safety.

Paint Preparation and Filtering

Use well-mixed, properly thinned paints and strain to prevent nozzle clogging and ensure smooth finishes.

Regular Cleaning and Maintenance

Clean the gun components after each use to maintain spray quality and prolong gun life.

Operator Training

Train operators on electrostatic spray principles and equipment handling to improve outcomes and reduce mistakes.

Common Challenges and Solutions

Uneven Coating or Poor Adhesion

Often caused by weak or intermittent electrostatic charge; check grounding and gun settings.

Excessive Overspray

Optimize spray pressure, gun distance, and electrostatic voltage to minimize overspray.

Nozzle Clogging

Regularly clean nozzles and strain paints before use.

Paint Compatibility Issues

Always verify that the spray gun is suitable for the specific paint or coating you use.

Frequently Asked Questions (FAQ)

1. Can electrostatic spray guns work with all types of paint?

Most electrostatic spray guns can work with water-based, solvent-based, and powder coatings, but it is essential to check specific compatibility for each model.

2. Do budget electrostatic spray guns offer comparable quality to premium models?

While budget models may lack some advanced features of premium guns, many deliver excellent performance for SMEs if used correctly.

3. How much paint savings can I expect using an electrostatic spray gun?

Typically, electrostatic guns offer up to 30-50% paint savings compared to conventional spray methods.

4. Are electrostatic spray guns suitable for both indoor and outdoor applications?

Yes, but adequate ventilation and grounding measures must be maintained, especially indoors.

5. What maintenance is needed for electrostatic spray guns?

Regular cleaning of nozzles, checking for wear, and proper storage are crucial to maintaining optimal functionality.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.