Content Menu

● Understanding Electrostatic Spray Gun Systems

>> What Is an Electrostatic Spray Gun?

>> Why Automate Electrostatic Spraying?

● Key Automation Components for Electrostatic Spray Gun Systems

>> Robotic Arms and Motion Control

>> Automated Spray Controllers

>> Vision Systems and Sensors

>> Material Delivery Integration

● Leading Automation Solutions Applicable to Electrostatic Spray Systems

>> Collaborative Robots (Cobots)

>> Fully Integrated Robotic Spray Booths

>> Automated Turntables and Positioners

>> AI-Driven Spray Optimization

● Benefits of Automating Electrostatic Spray Gun Systems

>> Enhanced Coating Quality and Consistency

>> Increased Production Efficiency

>> Material Savings and Environmental Impact

>> Worker Safety and Ergonomics

● Industry Applications Leveraging Automated Electrostatic Spray Systems

>> Automotive Manufacturing

>> Electronics and Appliances

>> Aerospace and Defense

>> Food Packaging Industry

● Implementation Considerations for Automation

>> System Compatibility and Integration

>> Training and Workforce Adaptation

>> Maintenance and Support Infrastructure

>> Cost-Benefit Analysis

● Best Practices for Optimizing Automated Electrostatic Spray Gun Systems

>> Regular Calibration and Validation

>> Environmental Control Management

>> Continuous Data Monitoring

● Frequently Asked Questions about Automation in Electrostatic Spray Gun Systems

Electrostatic spray guns are transformative in industrial coating and painting applications, providing excellent finish quality, higher transfer efficiency, and reduced waste. Integrating automation with electrostatic spray gun systems further enhances performance, consistency, and operational efficiency. In this article, we explore the best automation solutions tailored for electrostatic spray gun systems, presenting cutting-edge technologies, system components, benefits, and practical considerations for various industries.

Understanding Electrostatic Spray Gun Systems

What Is an Electrostatic Spray Gun?

An electrostatic spray gun applies charged particles of paint or coating material to a grounded surface. The gun imparts an electrical charge to the spray droplets, creating an attractive force between the droplets and the object. This results in uniform coverage and less overspray.

Why Automate Electrostatic Spraying?

Manual operation of electrostatic spray guns limits efficiency and consistency, especially in large-scale or high-volume applications. Automation brings precision, repeatability, and speed, drastically improving productivity while maintaining high-quality finishes.

Key Automation Components for Electrostatic Spray Gun Systems

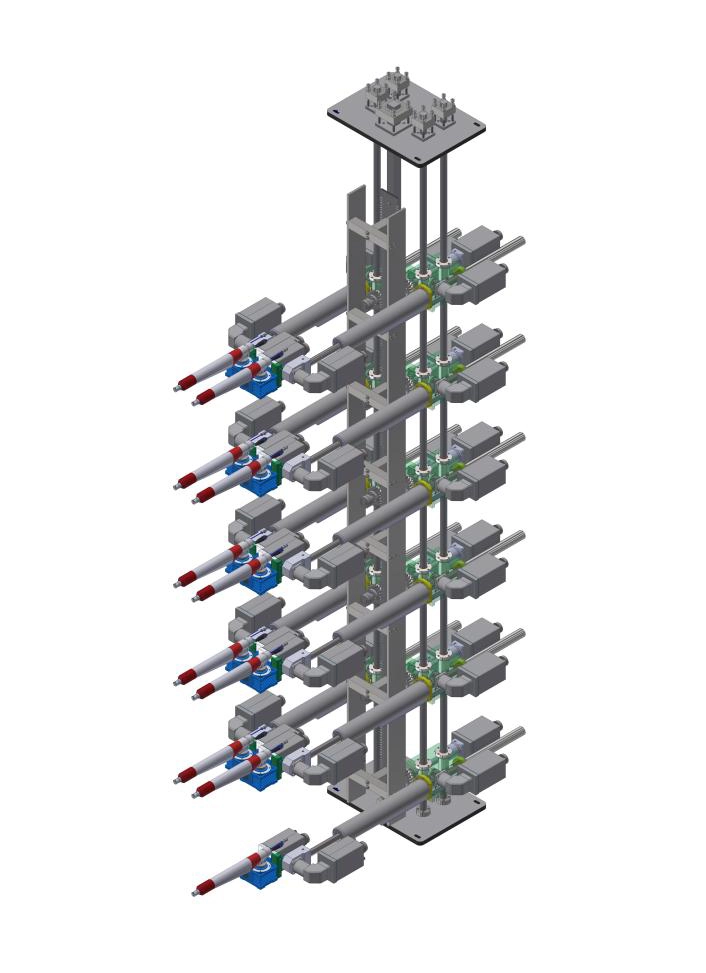

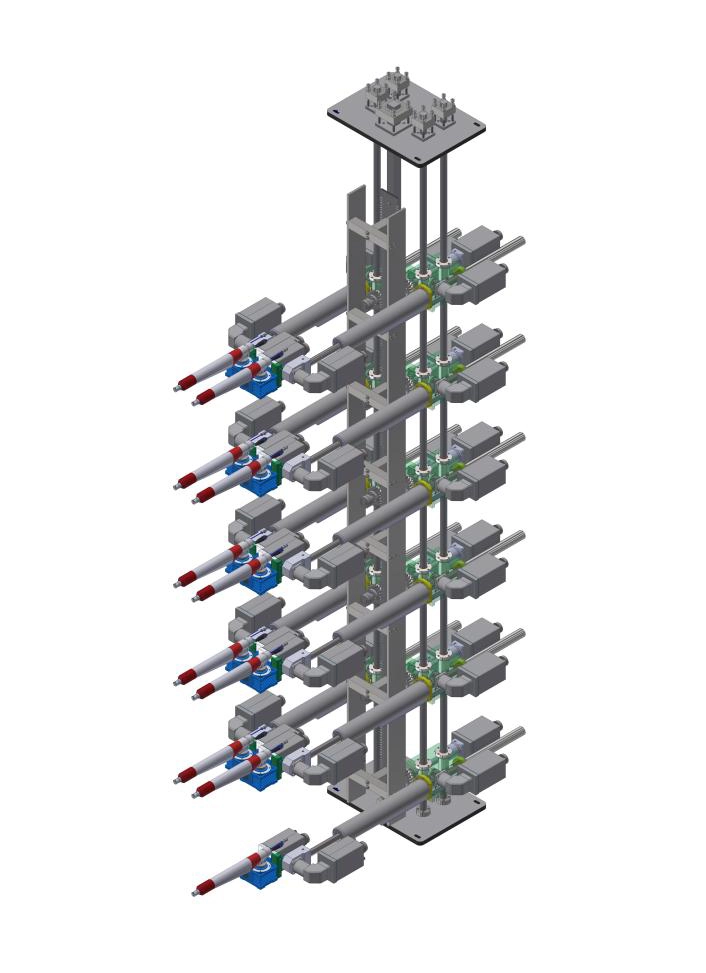

Robotic Arms and Motion Control

Robotic arms provide precise control over the spray gun movement. With programmable motion sequences, they can navigate complex geometries and maintain consistent spray distances and angles for optimal coating.

- Multi-axis robots enable movement in 3D space.

- Synchronization with conveyor systems ensures seamless part handling.

- Advanced motion controllers facilitate adaptive speed and path adjustments.

Automated Spray Controllers

Spray controllers regulate parameters such as voltage, current, material flow rate, and spray pattern automatically. These controllers adapt to changing conditions or part variations, optimizing spray quality.

- Real-time monitoring of electrostatic charge levels.

- Feedback loops to maintain consistent atomization.

- Programmable settings for different materials or coatings.

Vision Systems and Sensors

Vision systems equipped with cameras and laser scanners enable the robot to detect part position, shape, and surface condition for precise spraying.

- 3D scanning maps the target surface.

- Optical sensors detect defects or missed areas.

- Integration with AI enables dynamic path correction.

Material Delivery Integration

Automated supply systems ensure uninterrupted flow of coating material to the spray guns, reducing manual intervention.

- Automated pumps controlling flow rates.

- Filtration and mixing units ensuring material consistency.

- Scheduled maintenance alerts to avoid downtime.

Leading Automation Solutions Applicable to Electrostatic Spray Systems

Collaborative Robots (Cobots)

Cobots are designed to work alongside human operators safely. Their ease of programming and flexibility make them ideal for smaller operations or those transitioning into automation.

- Easy setup without requiring extensive programming knowledge.

- Adapted with electrostatic spray gun mounts.

- Ability to quickly change paint colors or coating types.

Fully Integrated Robotic Spray Booths

These booths combine robotics, automation controls, filtration, and environmental controls into a turnkey solution.

- Controlled atmosphere to optimize paint curing.

- Dust and overspray containment.

- Integrated quality control systems.

Automated Turntables and Positioners

For parts requiring multi-angle spraying, automated turntables rotate the object to expose all surfaces uniformly.

- Synchronization with robotic arms.

- Programmable rotation speeds and angles.

- Compact footprint for space efficiency.

AI-Driven Spray Optimization

Artificial intelligence systems analyze spray patterns, environmental factors, and material properties to fine-tune settings in real-time.

- Machine learning detects paint waste and corrects overspray.

- Predictive maintenance scheduling.

- Reports and analytics for process improvement.

Benefits of Automating Electrostatic Spray Gun Systems

Enhanced Coating Quality and Consistency

Automated systems eliminate human error, maintaining consistent voltage, distance, and movement speed, resulting in uniform and defect-free coatings.

Increased Production Efficiency

Robotic spray units operate continuously with minimal downtime and can handle high throughput, increasing overall output.

Material Savings and Environmental Impact

Improved transfer efficiency reduces wasted paint and solvent emissions, lowering costs and environmental footprint.

Worker Safety and Ergonomics

Automation removes operators from exposure to hazardous chemicals and repetitive strain tasks, improving workplace safety.

Industry Applications Leveraging Automated Electrostatic Spray Systems

Automotive Manufacturing

High volumes of car bodies and parts undergo electrostatic painting with robotic spray systems to ensure uniform finish and fast cycle times.

Electronics and Appliances

Compact components requiring precise coating benefit from automated micro-spray electrostatics integrated with inspection cameras.

Aerospace and Defense

Strict quality standards and complex geometries make automated electrostatic spray ideal for aircraft components and defense equipment.

Food Packaging Industry

Electrostatic spray guns apply coatings on packaging with automation ensuring sanitary standards and minimal contamination.

Implementation Considerations for Automation

System Compatibility and Integration

Automated electrostatic spray solutions should be compatible with existing manufacturing lines and support integration with ERP and MES systems for monitoring and control.

Training and Workforce Adaptation

Employees need training on new automated equipment for operation, maintenance, and troubleshooting to maximize ROI.

Maintenance and Support Infrastructure

Plans for preventive maintenance, spare parts availability, and supplier support are crucial for continuous uptime.

Cost-Benefit Analysis

Though upfront costs can be high, long-term savings on materials, labor, and enhanced productivity justify investment.

Best Practices for Optimizing Automated Electrostatic Spray Gun Systems

Regular Calibration and Validation

Routine checks on voltage output, spray pattern, and robot precision help maintain system accuracy.

Environmental Control Management

Controlling temperature, humidity, and airflow in the spray booth improves coating adhesion and finish quality.

Continuous Data Monitoring

Use of IoT sensors and data analytics allows proactive adjustments and early detection of process deviations.

Frequently Asked Questions about Automation in Electrostatic Spray Gun Systems

Q1: How does automation improve electrostatic spray gun efficiency?

Automation ensures precise control over spray parameters and movement, reducing paint waste and increasing coating uniformity, which boosts overall efficiency.

Q2: Can automated electrostatic spray systems handle different coating materials?

Yes, advanced automation solutions can be programmed to accommodate a variety of coatings by adjusting spray parameters automatically.

Q3: What safety advantages does automation provide in electrostatic spraying?

Automating spraying reduces human exposure to toxic fumes and chemicals, minimizes repetitive strain injuries, and improves workplace safety through controlled environments.

Q4: How difficult is it to integrate automation into existing electrostatic spray applications?

Integration complexity varies but can be streamlined with modular robotic systems, compatible software, and expert consultation to retrofit current lines.

Q5: What maintenance is required for automated electrostatic spray systems?

Maintenance includes regular calibration of spray guns and robots, inspection of electrical components, cleaning of nozzles, and software updates for control systems.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.