Content Menu

● Understanding Ramseier Koatings Spray Gun Technology

>> What is a Ramseier Koatings Spray Gun?

>> How Does It Work?

● Key Benefits of Using Ramseier Koatings Spray Gun Units

>> 1. Enhanced Transfer Efficiency

>> 2. Improved Finish Quality

>> 3. Versatility in Coating Applications

>> 4. Reduced Overspray and Waste

>> 5. Cost-Effectiveness

● Applications of Ramseier Koatings Spray Guns

>> Automotive Industry

>> Furniture and Woodworking

>> Metal Manufacturing

>> Aerospace Industry

>> Custom Coating Jobs

● Maintenance and Care of Ramseier Koatings Spray Guns

>> Regular Cleaning

>> Inspection of Components

>> Calibration

● Conclusion

>> Frequently Asked Questions

In the realm of industrial coating, the choice of equipment can significantly influence the quality, efficiency, and cost-effectiveness of the coating process. Among the various options available, the Ramseier Koatings spray gun unit stands out for its advanced technology and numerous benefits. This article delves into the advantages of using a Ramseier Koatings spray gun unit in industrial coating applications, exploring its features, operational benefits, and the impact it has on various industries.

Understanding Ramseier Koatings Spray Gun Technology

What is a Ramseier Koatings Spray Gun?

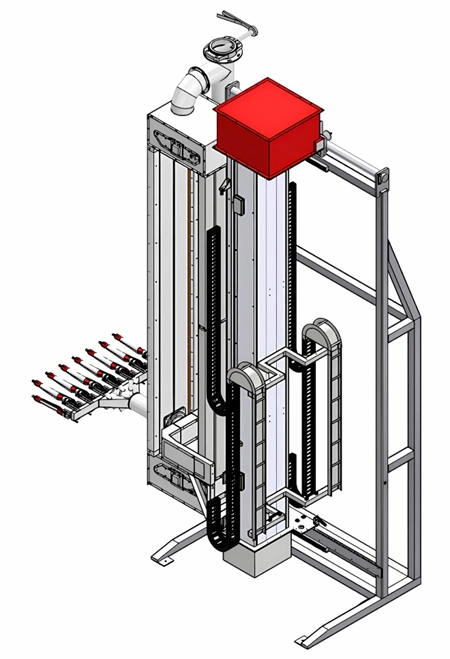

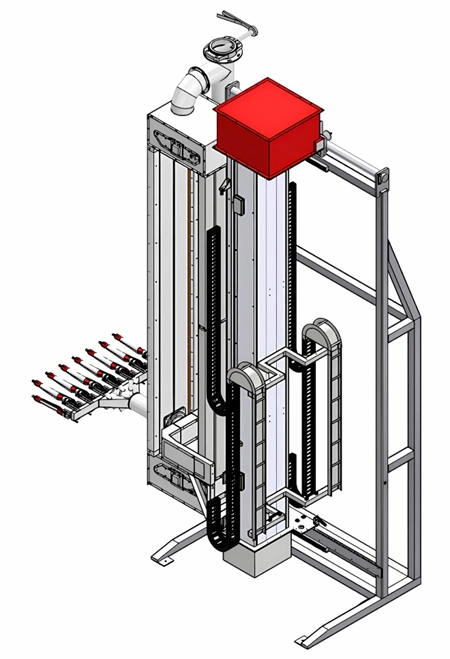

A Ramseier Koatings spray gun is a specialized tool designed for applying coatings, particularly powder coatings, in industrial settings. These spray guns utilize electrostatic technology, which charges the coating particles, allowing them to adhere more effectively to the surface being coated. This technology not only enhances the quality of the finish but also improves transfer efficiency, reducing waste.

How Does It Work?

The operation of a Ramseier Koatings spray gun involves several key components:

1. Electrostatic Charging: The spray gun generates a high voltage that charges the coating particles negatively.

2. Spraying Mechanism: The charged particles are propelled through the nozzle of the gun and directed towards the grounded workpiece.

3. Adhesion: The electrostatic attraction between the charged particles and the grounded surface ensures an even and consistent coating.

This process results in a superior finish with minimal overspray, making it an ideal choice for various industrial applications.

Key Benefits of Using Ramseier Koatings Spray Gun Units

1. Enhanced Transfer Efficiency

One of the most significant advantages of using a Ramseier Koatings spray gun is its high transfer efficiency. Traditional spray methods often result in a considerable amount of paint being wasted due to overspray. In contrast, the electrostatic technology used in Ramseier guns allows for a more efficient application, ensuring that a higher percentage of the coating reaches the intended surface. This not only reduces material costs but also minimizes environmental impact.

2. Improved Finish Quality

The precision offered by Ramseier Koatings spray guns leads to a superior finish quality. The electrostatic attraction ensures that the coating is applied evenly, resulting in a smooth and consistent surface. This is particularly important in industries where aesthetics and durability are paramount, such as automotive and furniture manufacturing.

3. Versatility in Coating Applications

Ramseier Koatings spray guns are versatile and can be used with a wide range of coating materials, including various types of powders and paints. This adaptability makes them suitable for different industries, from automotive to aerospace, where specific coating requirements may vary. The ability to switch between different coatings without significant downtime enhances productivity.

4. Reduced Overspray and Waste

The design of the Ramseier Koatings spray gun minimizes overspray, which is a common issue in traditional spray applications. By ensuring that more coating material adheres to the surface rather than being lost to the environment, companies can achieve significant cost savings. Additionally, reduced overspray contributes to a cleaner working environment, enhancing safety and compliance with environmental regulations.

5. Cost-Effectiveness

While the initial investment in a Ramseier Koatings spray gun unit may be higher than traditional spray equipment, the long-term savings are substantial. The combination of reduced material waste, improved efficiency, and enhanced finish quality leads to lower overall operational costs. Companies can expect a quicker return on investment as they save on both materials and labor.

Applications of Ramseier Koatings Spray Guns

Automotive Industry

In the automotive sector, the need for high-quality finishes that can withstand harsh conditions is critical. Ramseier Koatings spray guns provide the durability and aesthetic appeal required for automotive coatings. The electrostatic application ensures that every part is coated evenly, enhancing both appearance and protection against corrosion.

Furniture and Woodworking

The furniture industry benefits significantly from the precision and quality that Ramseier Koatings spray guns offer. Whether applying a clear coat or a colored finish, these guns ensure that every piece is coated evenly, enhancing the product's durability and appearance. The versatility of the spray gun allows for various finishes, catering to different design preferences.

Metal Manufacturing

Metal components often require robust coatings to protect against corrosion and wear. The high transfer efficiency of Ramseier Koatings spray guns ensures that coatings are applied evenly and with minimal waste, making them ideal for metal manufacturing applications. This is crucial in industries where metal components are exposed to harsh environmental conditions.

Aerospace Industry

In aerospace, the requirements for coatings are stringent, with a focus on weight reduction and durability. Ramseier Koatings spray guns can apply lightweight coatings that meet these specifications while providing excellent protection against environmental factors. The precision of the application process is vital in ensuring the safety and performance of aerospace components.

Custom Coating Jobs

For businesses that require custom coating solutions, Ramseier Koatings spray guns offer the flexibility needed to adapt to various projects. The ability to switch between different coatings and adjust application settings allows for tailored solutions that meet specific customer needs.

Maintenance and Care of Ramseier Koatings Spray Guns

Regular Cleaning

To maintain the performance of a Ramseier Koatings spray gun, regular cleaning is essential. After each use, the gun should be thoroughly cleaned to prevent any buildup of coating material that could affect its operation. This includes disassembling the gun and cleaning all components, including the nozzle and fluid passages.

Inspection of Components

Routine inspections of the spray gun components are crucial to ensure optimal performance. This includes checking for wear and tear on the nozzle, seals, and other parts. Any damaged components should be replaced promptly to avoid compromising the quality of the coating application.

Calibration

Regular calibration of the spray gun is necessary to maintain its efficiency and accuracy. This involves adjusting the settings to ensure that the electrostatic charge and spray pattern are optimized for the specific coating being used. Proper calibration helps in achieving consistent results across different applications.

Conclusion

The Ramseier Koatings spray gun unit represents a significant advancement in industrial coating technology. Its benefits, including enhanced transfer efficiency, improved finish quality, and versatility in applications, make it an invaluable tool for various industries. By investing in this technology, companies can achieve cost savings, reduce waste, and improve the overall quality of their coatings. As industries continue to evolve, the adoption of advanced coating technologies like those offered by Ramseier Koatings will be essential for maintaining competitiveness and meeting customer demands.

Frequently Asked Questions

1. What is the primary benefit of using a Ramseier Koatings spray gun?

- The primary benefit is improved transfer efficiency, which reduces paint waste and enhances finish quality.

2. How does electrostatic technology improve coating applications?

- Electrostatic technology charges the coating particles, allowing them to adhere better to the surface, resulting in a more even application and less overspray.

3. Can Ramseier Koatings spray guns be used with different types of coatings?

- Yes, they are versatile and can be used with various powder and paint types, making them suitable for multiple industries.

4. What maintenance is required for Ramseier Koatings spray guns?

- Regular cleaning, inspection of components, and calibration are essential to maintain optimal performance.

5. Are Ramseier Koatings spray guns cost-effective in the long run?

- Yes, while the initial investment may be higher, the long-term savings from reduced waste and improved efficiency lead to lower operational costs.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.