Content Menu

● Understanding Automatic Electrostatic Spray Guns

>> What is an Automatic Electrostatic Spray Gun?

>> How Does Electrostatic Spray Technology Work?

● Advantages of Using Automatic Electrostatic Spray Guns

>> Increased Transfer Efficiency

>> Superior Finish Quality

>> Environmental and Safety Benefits

● Applications Across Different Materials

>> Metal Coatings

>>> Automotive Industry

>>> Aerospace

>>> Industrial Equipment and Machinery

>> Plastic and Composite Materials

>> Wood Surfaces

>> Glass and Ceramics

>> Packaging Materials

● Challenges and Considerations for Different Materials

>> Surface Conductivity

>> Coating Viscosity and Thickness

>> Environmental Conditions

● Technologies Enhancing Automatic Electrostatic Spray Guns

>> High Voltage and High Current Guns

>> Robotic and Programmable Systems

>> Maintenance and Durability Features

● Industry Case Studies of Application

>> Automotive Manufacturing

>> Furniture Production

>> Aerospace Coatings

>> Packaging Industry

● Frequently Asked Questions (FAQs)

>> 1. What materials can be coated with an automatic electrostatic spray gun?

>> 2. How does electrostatic spraying reduce paint waste?

>> 3. Are electrostatic spray guns safe to use?

>> 4. Can electrostatic spray guns handle different paint viscosities?

>> 5. What industries benefit most from automatic electrostatic spray guns?

The rapid evolution of industrial finishing and coating technologies has made automatic electrostatic spray guns essential across many sectors. These advanced tools improve application efficiency, reduce material waste, and provide a superior finish on various substrates. This article explores the diverse applications of automatic electrostatic spray guns across different materials, highlights their advantages, and explains how this technology transforms manufacturing and finishing processes.

Understanding Automatic Electrostatic Spray Guns

What is an Automatic Electrostatic Spray Gun?

An automatic electrostatic spray gun is a mechanized device that applies coatings by electrically charging paint or other liquid particles. The charged particles are attracted to oppositely charged or grounded surfaces, ensuring even coating adhesion. Automation allows continuous and consistent application on production lines, enhancing throughput and quality.

How Does Electrostatic Spray Technology Work?

The core principle of electrostatic spraying involves charging paint particles positively while the target surface is grounded or negatively charged. This charge difference pulls the paint toward the object, dramatically reducing overspray and enhancing coverage quality. Paint particles can wrap around complex shapes for complete coverage, which conventional spraying methods cannot achieve.

Advantages of Using Automatic Electrostatic Spray Guns

Increased Transfer Efficiency

Automatic electrostatic spray guns typically achieve transfer efficiencies of up to 90-95%. This means a higher percentage of coating material adheres to the target surface compared to traditional methods, decreasing waste and lowering material costs.

Superior Finish Quality

Because charged particles repel each other, the spray mist becomes finer and more uniform, resulting in a smooth, even finish without runs or drips. The wrapping effect enhances coating coverage on complex geometries.

Environmental and Safety Benefits

Reduced overspray means less volatile organic compounds (VOC) are released into the environment, improving air quality and worker safety. Moreover, less cleaning and rework are required, minimizing hazardous waste generation.

Applications Across Different Materials

Automatic electrostatic spray guns are versatile tools used in a wide range of industries and for coating diverse materials. The technology adapts well to different surface properties, viscosities, and application requirements.

Metal Coatings

Automotive Industry

In automotive manufacturing and refinishing, electrostatic spray guns are paramount. Car bodies, frames, bumpers, and parts are coated with precision and speed, ensuring durable and aesthetically pleasing finishes. The technology supports frequent color changes while maintaining high quality across large production volumes.

Aerospace

Coatings applied via electrostatic spray guns protect aircraft components against corrosion and environmental wear. The ability to uniformly coat complex shapes such as wings and fuselage parts enhances durability and reduces maintenance costs.

Industrial Equipment and Machinery

Metal furniture, agricultural implements, construction equipment, and electrical housings benefit from electrostatic coatings that resist corrosion and abrasion, prolonging asset life and maintaining appearance.

Plastic and Composite Materials

Electrostatic spray technology has evolved to handle non-conductive surfaces such as plastics, composites, and fiberglass. Special conductive primers or pre-treatments enable effective charge adherence. This expands application possibilities in industries like automotive interiors, consumer electronics housings, and sports equipment.

Wood Surfaces

Wood products, including furniture and cabinetry, gain superior finish qualities when coated with electrostatic spray guns. The technology supports various coatings, including stains, lacquers, and paints, creating uniform coverage on porous surfaces with minimal waste.

Glass and Ceramics

Electrostatic spraying is also effective for glassware and ceramic coatings, such as decorative finishes or protective layers. The technology provides smooth, consistent layers even on fragile or intricate shapes.

Packaging Materials

In industries like food and beverage, electrostatic spray guns coat packaging materials to apply safety and protective films that extend shelf life and enhance product appeal. The precision coating aids in maintaining hygiene and product integrity.

Challenges and Considerations for Different Materials

Surface Conductivity

Electrostatic spraying requires the surface to be conductive or grounded to attract charged particles effectively. For non-conductive materials like plastics or glass, additional grounding or conductive coatings may be necessary.

Coating Viscosity and Thickness

Material viscosity impacts atomization and charge retention. Automatic electrostatic spray guns are often paired with pressure and flow controls to handle a range of viscosities from thin liquid paints to thicker coatings, ensuring optimal finish and adhesion.

Environmental Conditions

Humidity and temperature can affect electrostatic charging and spray behavior. Controlled environments or advanced equipment with adaptive controls help maintain consistent results.

Technologies Enhancing Automatic Electrostatic Spray Guns

High Voltage and High Current Guns

Modern spray guns combine high voltage and high current for optimal particle charge, ensuring efficient paint transportation and adherence, even under challenging conditions.

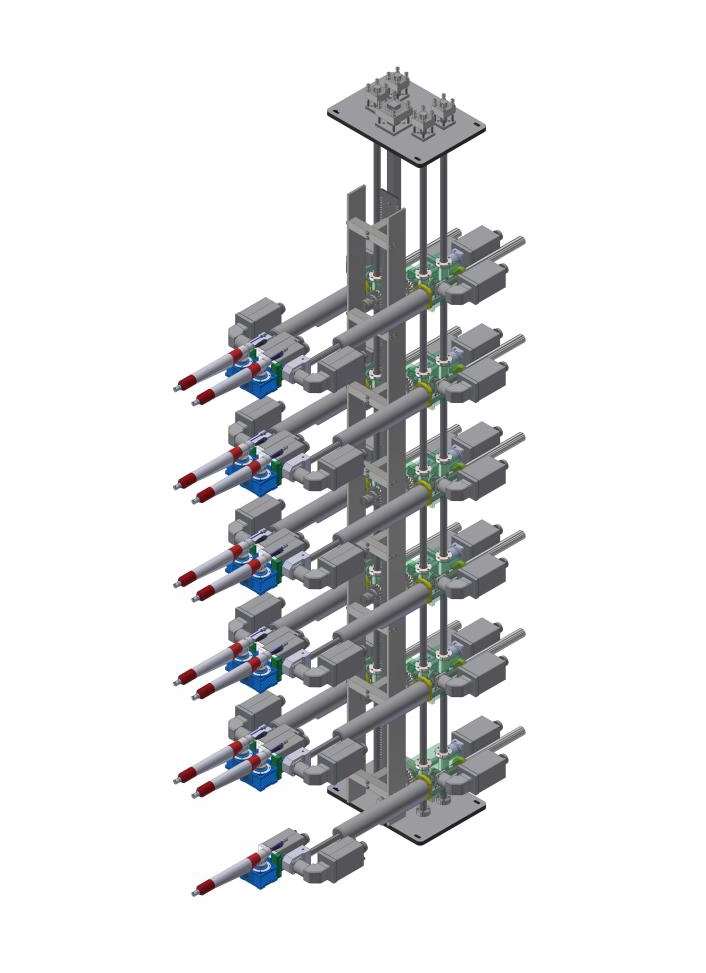

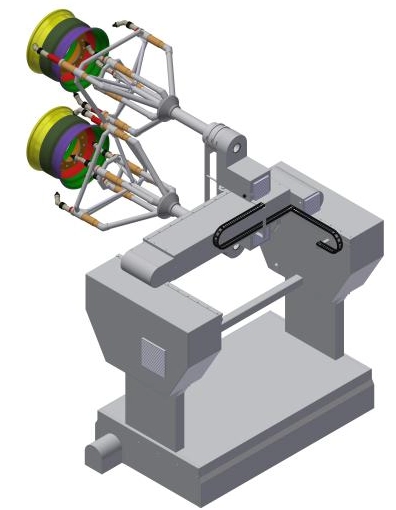

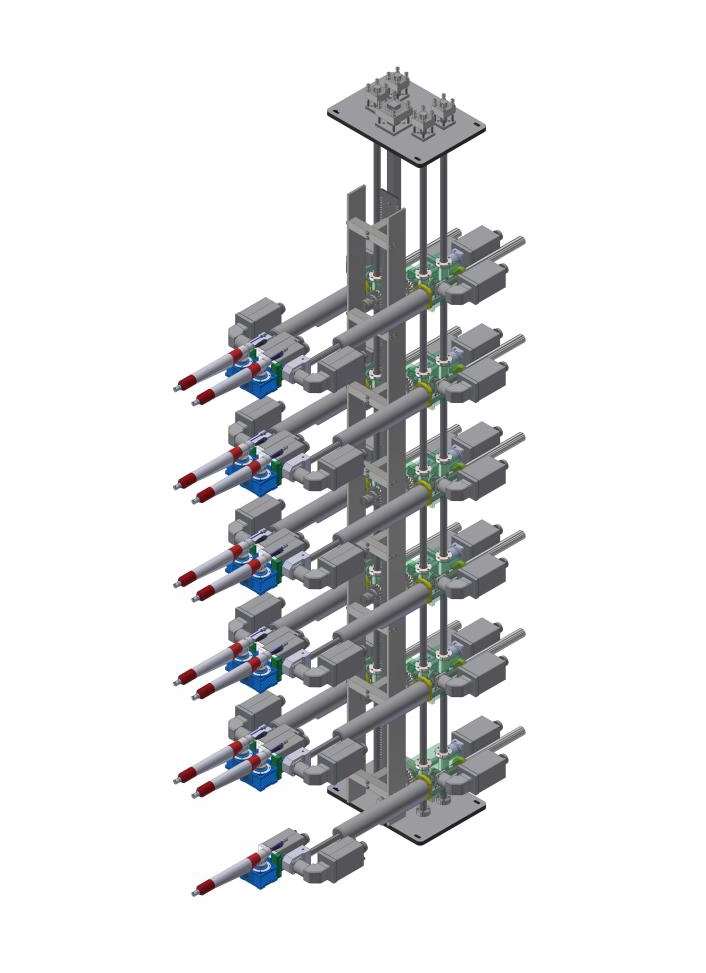

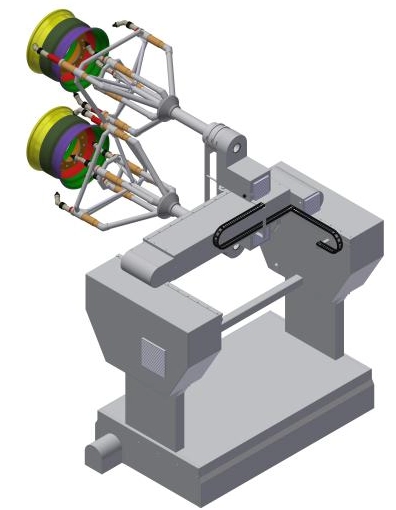

Robotic and Programmable Systems

Integration with robotic arms and PLC systems enables precise control of spray patterns, speeds, and coating thicknesses, improving efficiency and repeatability on production lines.

Maintenance and Durability Features

Design improvements focus on ease of disassembly for cleaning, durable parts resistant to solvents and wear, and built-in safety controls to prevent malfunction and ensure operator safety.

Industry Case Studies of Application

Automotive Manufacturing

Robotic electrostatic spray guns automate car painting lines providing fast cycles, reduced waste, and top-quality finishes in varied colors. These systems have revolutionized auto manufacturing with consistent and cost-effective coating solutions.

Furniture Production

Electrostatic spray guns in wood and metal furniture factories deliver uniform, durable finishes. The reduction in paint usage lowers costs, and improved coverage leads to fewer defects and rework.

Aerospace Coatings

Aerospace parts sprayed with electrostatic guns achieve corrosion resistance and meet strict aerospace quality standards. The technology supports protective coatings vital for aircraft longevity.

Packaging Industry

Food packaging coated with electrostatic spray films extends shelf life and adds protective barriers. Precision application reduces material usage and contamination risks.

Frequently Asked Questions (FAQs)

1. What materials can be coated with an automatic electrostatic spray gun?

Automatic electrostatic spray guns can coat metals, plastics, composites, wood, glass, ceramics, and packaging materials, provided the surface conductivity or grounding conditions are met.

2. How does electrostatic spraying reduce paint waste?

By charging paint particles and attracting them to the grounded surface, electrostatic spray guns minimize overspray and bounce-back, leading to up to 90-95% transfer efficiency and less material wasted.

3. Are electrostatic spray guns safe to use?

Yes, modern electrostatic spray guns include safety features and reduce inhalation risks by reducing overspray and VOC emissions, making workplaces safer compared to conventional spray methods.

4. Can electrostatic spray guns handle different paint viscosities?

Yes, these guns can be adjusted or paired with appropriate pumps to apply a wide range of coating viscosities, from thin liquid paints to thicker materials.

5. What industries benefit most from automatic electrostatic spray guns?

Automotive, aerospace, furniture, industrial equipment, packaging, and construction industries are primary beneficiaries, where high-quality, efficient, and eco-friendly coating is critical.

[1](https://www.graco.com/us/en/in-plant-manufacturing/products/liquid-coating/spray-booth/spray-guns-applicators/electrostatic-paint-spray-guns.html)

[2](https://www.sames.com/usa/en/solutions-airspray-electrostatic-solvent-based-for-one-painter.html)

[3](https://elmbridgeuk.com/learning-hub/7-reasons-to-use-an-electrostatic-spray-gun/)

[4](https://bfsales.com/what-is-an-electrostatic-spray-gun/)

[5](https://www.codinter.com/en/automatic-spray-guns-a-complete-guide/)

[6](https://ai.otson.com/coating-electrostatic-spray/ots-3000-manual-liquid-electrostatic-spray-gun-led-version/)

[7](https://www.chreed.com/electrostatic-spray-guns-what-are-the-benefits-2/)

[8](https://www.hdaspraygun.com/wap/news-detail-204.html)

[9](https://patvin.co.in/capabilities-overview/paint-application-system/applicators/guns/automatic-paint-guns/electrostatic-paint-gun/)

[10](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/electrostatic-spray-gun-basics.html)

[11](https://www.precisiondipcoating.com/blog/the-benefits-of-the-electrostatic-spraying-method)

[12](https://www.linkedin.com/pulse/electrostatic-paint-spray-gun-real-oeiuc)

[13](https://totalfinishingsupplies.com/blogs/dispelling-myths-about-electrostatic-sprayers-affordable-and-safe-solutions/dispelling-myths-about-electrostatic-sprayers-affordable-and-safe-solutions)

[14](https://www.finishingconsultants.com/electrostatic-painting.php)

[15](https://www.ghasterpaintinginc.com/blog/what-electrostatic-painting-is-and-why-it-works-so-well/)

[16](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/how-electrostatic-guns-can-benefit-your-facility.html)

[17](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/advantages-of-spraying-with-electrostatic-guns.html)

[18](https://www.youtube.com/watch?v=vcVYfVoXAC8)

[19](https://www.cetinc.com/should-i-be-using-electrostatic-spray/)

[20](https://ai.otson.com/aerospace-industry-liquid-electrostatic-spray-coating-technologies/)

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.