Content Menu

● Understanding Electrostatic Spray Technology

>> What is Electrostatic Spraying?

>> How Does It Work?

● Key Components of Manual Electrostatic Spray Guns

>> The Spray Gun Design

>> The Electrostatic Charging Mechanism

● Advantages of Manual Electrostatic Spray Guns

>> Improved Transfer Efficiency

>> Reduced Environmental Impact

>> Versatility in Applications

● Challenges Facing Manual Electrostatic Spray Guns

>> Skill Dependency

>> Equipment Maintenance

>> Initial Cost

● Innovations in Electrostatic Spray Technology

>> Advancements in Nozzle Design

>> Smart Technology Integration

>> Eco-Friendly Coatings

● Conclusion

>> Frequently Asked Questions

Electrostatic spray guns have revolutionized the painting and coating industry by providing a more efficient and environmentally friendly method of applying coatings. This article explores the technology behind manual electrostatic spray guns, their components, advantages, and applications, as well as the challenges they face in modern manufacturing.

Understanding Electrostatic Spray Technology

What is Electrostatic Spraying?

Electrostatic spraying is a technique that uses electrical charges to improve the application of paint and coatings. In this process, the paint particles are given a positive charge as they exit the spray gun, while the object being painted is grounded or negatively charged. This creates an attractive force that helps the paint adhere to the surface, resulting in a more uniform coating with less overspray.

How Does It Work?

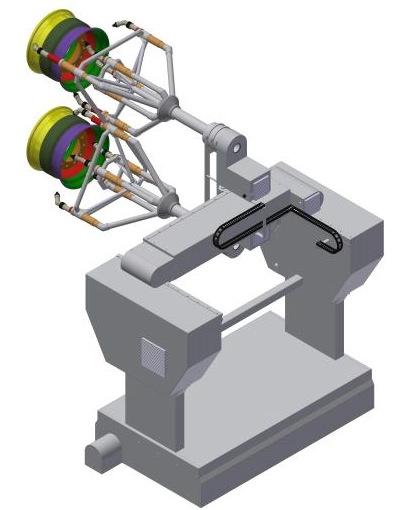

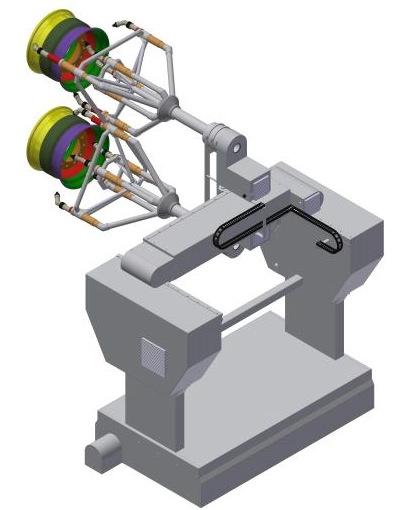

The operation of a manual electrostatic spray gun involves several key components:

1. Electrostatic Generator: This device generates the electrical charge needed to charge the paint particles. It typically operates at high voltages, often around 60 kV, to ensure effective charging.

2. Spray Gun: The spray gun itself is designed to atomize the paint into fine particles. It features a nozzle that controls the spray pattern and a trigger mechanism that allows the operator to control the flow of paint.

3. Air Supply: Compressed air is used to atomize the paint and propel it towards the surface. The combination of air pressure and electrostatic charge enhances the transfer efficiency of the paint.

4. Grounding System: The object being painted must be properly grounded to create the necessary electrical field. This grounding can be achieved through direct contact with the surface or by using conductive materials.

Key Components of Manual Electrostatic Spray Guns

The Spray Gun Design

Manual electrostatic spray guns are designed for ease of use and efficiency. They typically feature:

- Adjustable Nozzles: Different nozzle sizes and shapes allow for various spray patterns, accommodating different types of coatings and applications.

- Ergonomic Handles: Designed for comfort during extended use, these handles reduce operator fatigue.

- Easy Maintenance Features: Many models include removable parts for easy cleaning and maintenance, ensuring longevity and consistent performance.

The Electrostatic Charging Mechanism

The charging mechanism is crucial for the effectiveness of electrostatic spray guns. It works by:

- Ionization of Paint Particles: As the paint passes through the nozzle, it is ionized, gaining a positive charge.

- Attraction to the Substrate: The negatively charged surface of the object being painted attracts the positively charged paint particles, leading to a more efficient coating process.

Advantages of Manual Electrostatic Spray Guns

Improved Transfer Efficiency

One of the most significant benefits of using manual electrostatic spray guns is their high transfer efficiency. Traditional spray methods can result in significant overspray, leading to wasted materials and increased costs. In contrast, electrostatic guns can achieve transfer efficiencies of up to 90%, meaning more paint reaches the intended surface.

Reduced Environmental Impact

Electrostatic spraying is more environmentally friendly compared to conventional methods. The reduction in overspray not only conserves materials but also minimizes volatile organic compound (VOC) emissions, aligning with global sustainability goals.

Versatility in Applications

Manual electrostatic spray guns are suitable for a wide range of applications, including:

- Automotive Coatings: Ideal for achieving a smooth finish on vehicles.

- Industrial Equipment: Used for coating machinery and tools.

- Furniture Finishing: Provides a high-quality finish on wooden and metal furniture.

Challenges Facing Manual Electrostatic Spray Guns

Skill Dependency

While manual electrostatic spray guns offer many advantages, they also require skilled operators. The effectiveness of the spraying process can be significantly influenced by the operator's technique, including the distance from the surface, angle of application, and speed of movement.

Equipment Maintenance

Regular maintenance is essential to ensure optimal performance. This includes cleaning the spray gun after use, checking the electrostatic generator, and ensuring that the air supply is free of moisture and contaminants.

Initial Cost

The initial investment for manual electrostatic spray guns can be higher than traditional spray guns. However, the long-term savings from reduced material waste and improved efficiency often justify the upfront costs.

Innovations in Electrostatic Spray Technology

Advancements in Nozzle Design

Recent innovations in nozzle technology have led to the development of finer spray patterns, which enhance the quality of the finish and further improve transfer efficiency. These advancements allow for better control over the application process, making it easier to achieve desired results.

Smart Technology Integration

The integration of smart technology into electrostatic spray guns is on the rise. Features such as digital pressure gauges, automated flow control, and real-time monitoring systems are being incorporated to enhance user experience and improve application consistency.

Eco-Friendly Coatings

The demand for eco-friendly coatings is driving innovation in the electrostatic spray industry. Manufacturers are developing water-based and low-VOC coatings that work effectively with electrostatic spray technology, further reducing environmental impact.

Conclusion

Manual electrostatic spray guns represent a significant advancement in coating technology, offering numerous benefits over traditional methods. Their ability to improve transfer efficiency, reduce environmental impact, and provide versatility in applications makes them an essential tool in various industries. As technology continues to evolve, we can expect further innovations that will enhance the performance and usability of these spray guns.

Frequently Asked Questions

1. What is the main advantage of using an electrostatic spray gun?

- The main advantage is the high transfer efficiency, which reduces overspray and material waste.

2. How does the electrostatic charging process work?

- Paint particles are charged positively as they exit the gun, while the surface being painted is grounded, creating an attractive force.

3. What types of coatings can be used with manual electrostatic spray guns?

- They can be used with a variety of coatings, including water-based and solvent-based paints.

4. What maintenance is required for electrostatic spray guns?

- Regular cleaning, checking the electrostatic generator, and ensuring the air supply is clean are essential for optimal performance.

5. Are manual electrostatic spray guns suitable for all types of surfaces?

- Yes, they can be used on various surfaces, including metal, wood, and plastic, as long as the surface is properly prepared and grounded.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.