Content Menu

● Introduction to Automated Spray Booths

● Challenges Solved by Automated Spray Booths

>> Safety Risks

>> Material Waste and Cost Efficiency

>> Inconsistent Quality

>> High Labor Costs

● Benefits of Automated Spray Booth Systems

>> Speed and Efficiency

>> Enhanced Worker Safety

● Implementing Automated Spray Booth Systems

● Conclusion

● Frequently Asked Questions

● Citations:

Automatic spray booth systems have revolutionized the manufacturing industry by addressing several key challenges that traditional manual spray painting processes face. These challenges include safety risks, material waste, inconsistent quality, and high labor costs. In this article, we will explore how automated spray booths solve these issues and enhance overall efficiency and productivity.

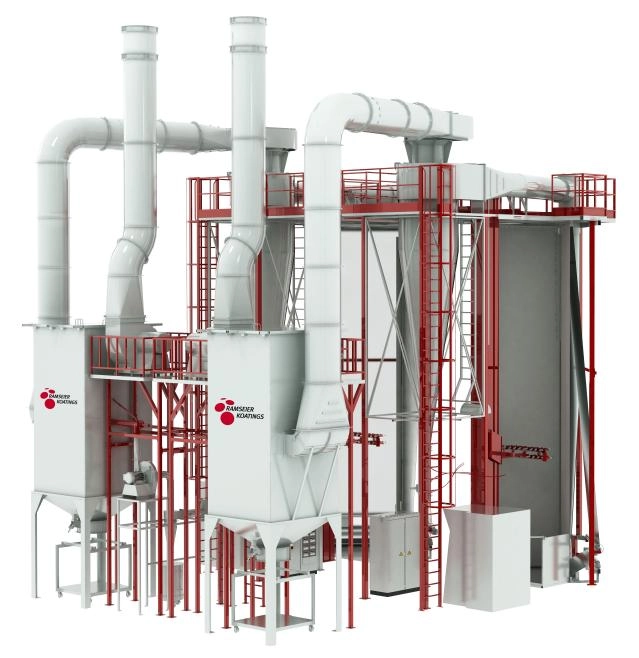

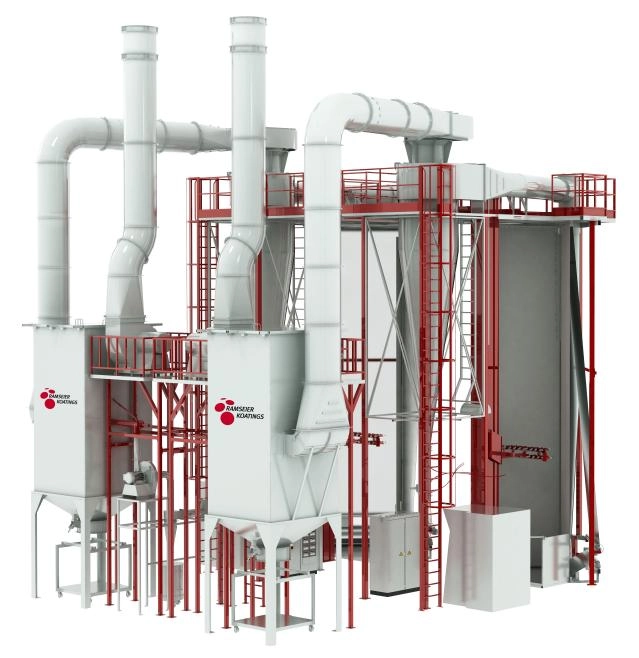

Introduction to Automated Spray Booths

Automated spray booths utilize advanced technology to control various aspects of the painting process, from airflow and temperature to paint application and curing times. These systems can be programmed to handle specific tasks, ensuring precision and repeatability. By automating the painting process, businesses can achieve greater efficiency, reduce errors, and improve overall productivity.

Challenges Solved by Automated Spray Booths

Safety Risks

Manual spray painting involves several health risks due to exposure to harmful chemicals and fumes. Workers are often required to wear protective gear, but even with precautions, there is still a risk of accidents and health issues. Automated spray booths significantly reduce these risks by containing the painting process within a controlled environment. Workers can monitor and control operations from a distance, minimizing exposure to hazardous substances.

Material Waste and Cost Efficiency

One of the major advantages of automatic spray booths is their ability to reduce waste. Transfer efficiency, or the amount of paint that actually adheres to the surface versus what is lost to overspray, is much higher in automated systems. This translates into less paint used per part, lowering material costs and reducing environmental impact. By optimizing paint usage, companies can save on materials and reduce cleanup time.

Inconsistent Quality

Manual spray painting relies heavily on operator skill, leading to variability in the finish quality. With automated spray booths, the process is controlled by robotics, which guarantees that each part receives an identical finish. Sensors and AI technology ensure that the spray pattern is adjusted in real-time, eliminating defects such as runs, drips, or uneven layers. This consistency is particularly important in industries where high-quality finishes are crucial, such as automotive or aerospace manufacturing.

High Labor Costs

Substantial operator time spent on initial spray setup and subsequent changeovers contributes to high labor expenses. Personnel need to readjust multiple settings when switching between part types manually. Automated systems can automate these adjustments with programmable controllers, cutting operator labor needs and simplifying changeovers between product variants.

Benefits of Automated Spray Booth Systems

Speed and Efficiency

An automatic spray booth can operate at speeds far beyond what manual operators can achieve. The conveyor systems used in automatic booths allow continuous painting, where parts move through the booth without stopping, ensuring a steady production rate. This leads to significant time savings, especially for high-volume operations such as automotive or electronics manufacturing.

Enhanced Worker Safety

Paint and coating materials often contain hazardous chemicals that can pose health risks to workers. Automatic spray booths significantly reduce human exposure to these harmful substances. Workers are not directly involved in the spray painting process, as the machinery does all the work inside a contained environment with proper ventilation.

Implementing Automated Spray Booth Systems

Implementing automated spray booth systems requires careful planning and investment. While the initial costs of purchasing and integrating automated booths can be high, they can quickly lead to notable savings for operators. These systems can be optimized for specific production demands, ensuring efficient paint application and reducing waste compared to conventional units.

Conclusion

In conclusion, automated spray booth systems offer a comprehensive solution to several challenges faced by traditional spray painting processes. By enhancing safety, reducing material waste, ensuring consistent quality, and lowering labor costs, these systems can significantly improve manufacturing efficiency and productivity. As technology continues to evolve, the benefits of automation in spray booth operations will only continue to grow.

---

Frequently Asked Questions

1. What are the primary benefits of using automated spray booths?

- The primary benefits include improved safety, reduced material waste, consistent quality, and enhanced efficiency.

2. How do automated spray booths reduce material waste?

- Automated spray booths reduce material waste by optimizing paint usage and minimizing overspray through higher transfer efficiency.

3. What safety risks are mitigated by automated spray booths?

- Automated spray booths mitigate safety risks by reducing worker exposure to harmful chemicals and fumes, and minimizing the risk of accidents.

4. How do automated systems improve the consistency of paint finishes?

- Automated systems improve consistency by using robotics and AI to ensure that each part receives an identical finish, eliminating variability caused by human error.

5. What are the initial costs associated with implementing automated spray booths?

- The initial costs include the purchase and integration of the automated system, which can be high but lead to long-term savings.

Citations:

[1] https://pfsspraybooths.com/common-spray-booth-mistakes-and-how-to-avoid-them

[2] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[3] https://arnoldmachine.com/resources/adhesive-spraying-equipment-problems-and-solutions/

[4] https://www.truteksystems.co.in/blogDetail/Common-Car-Paint-Booth-Problems-Solved-with-Trutek-Systems

[5] https://www.cxhuarui.com/The-Benefits-of-Using-an-Automatic-Spray-Booth-in-Manufacturing-id45271556.html

[6] https://macquarieairfiltration.com.au/common-spray-booth-problems-caused-by-poor-air-filtration/

[7] https://www.graco.com/gb/en/in-plant-manufacturing/solutions/articles/most-common-challenges-when-spraying-waterborne-materials-using-electrostatics.html

[8] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[9] https://www.accudraftpaintbooths.com/blog/3-common-paint-booth-problems-and-solutions/

[10] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/common-paint-booth-problems-and-how-to-fix-them

[11] https://www.hppneumatics.com/spray-booth-benefits/

[12] https://jmcautomotiveequipment.com/blog/common-issues-with-car-paint-booths-and-how-to-fix-them/

[13] https://www.paint-booths.com/blog/top-5-paint-booth-safety-measures/

[14] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/why-you-should-automate-your-paint-booth.html

[15] https://jmcautomotiveequipment.com/blog/car-spray-booth-solutions-for-the-most-common-challenges/

[16] https://www.duboisequipment.com/benefits-of-automated-spray-coating-systems/

[17] https://www.eng-tips.com/threads/spray-booths.237143/

[18] https://www.ramseierkoatings.com/automatic-vs-semi-automatic-spray-booth-systems-which-is-better.html

[19] https://chassislinersupply.com/blogs/news/make-the-most-of-your-automotive-spray-booth-with-our-top-6-maintenance-tips

[20] https://www.junair-spraybooths.co.uk/the-health-benefits-of-automated-spray-booths-and-how-they-can-help-your-business-reduce-occupational-health-risks/

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.