Content Menu

● Understanding Electrostatic Spray Guns

>> How Electrostatic Spray Guns Work

>> The Science Behind the Efficiency

● Key Advantages of Electrostatic Spray Guns Over Traditional Painting Tools

>> 1. Superior Transfer Efficiency

>> 2. Enhanced Coating Quality and Coverage

>> 3. Reduced Overspray and Environmental Impact

>> 4. Improved Operator Safety and Working Conditions

>> 5. Cost Savings and Return on Investment

● Technical Considerations and Limitations

>> Addressing the Faraday Cage Effect

>> Material Compatibility

● Practical Applications of Electrostatic Spray Guns

>> Industrial and Commercial Use

>> Manual vs. Automated Electrostatic Spraying

● Conclusion

● Frequently Asked Questions (FAQs)

Painting technology has evolved significantly over the years, with electrostatic spray guns emerging as a leading innovation in industrial and commercial coating applications. Compared to traditional painting tools such as conventional spray guns, brushes, and rollers, electrostatic spray guns offer superior efficiency, quality, and environmental benefits. This article explores the fundamental reasons why electrostatic spray guns are more efficient, how they work, and the advantages they bring to various painting operations.

Understanding Electrostatic Spray Guns

How Electrostatic Spray Guns Work

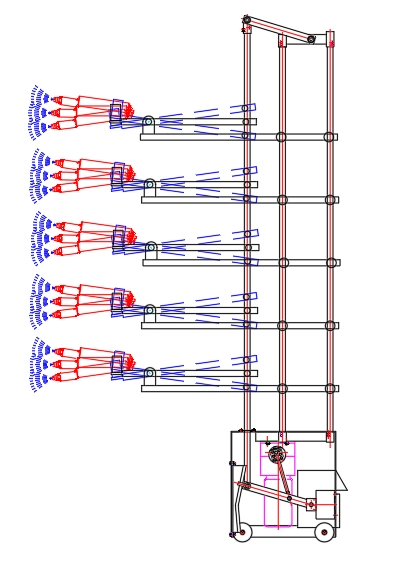

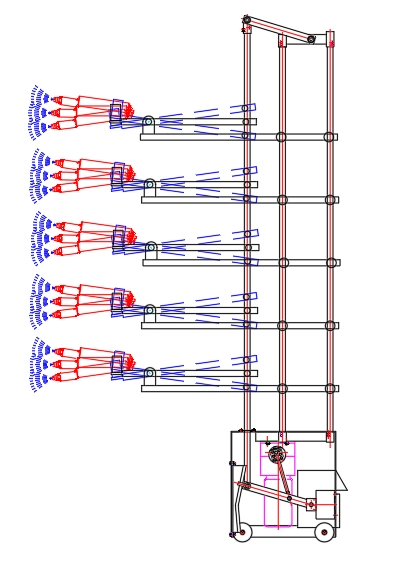

Electrostatic spray guns operate on the principle of electrostatic attraction. The paint particles are given a positive electrical charge as they exit the spray gun, while the object to be painted is grounded or negatively charged. This opposite charge creates a strong magnetic-like pull that attracts the paint particles directly to the surface, ensuring a more precise and uniform coating.

This process contrasts with conventional spray guns, which rely solely on air pressure to atomize and propel paint particles toward the surface without any electrical charge. As a result, conventional spraying often leads to significant paint overspray and wastage.

The Science Behind the Efficiency

The charged paint particles repel each other, creating a fine, even mist that wraps around the object being painted. This "wrap-around" effect allows paint to reach difficult areas such as corners, crevices, and the backside of tubular or irregularly shaped objects, which traditional spray guns often miss.

The magnetic attraction between the charged paint and the grounded surface minimizes overspray, reducing paint loss and environmental contamination. This mechanism is a key factor in the high transfer efficiency of electrostatic spray guns, which can reach up to 90-95%, compared to 40-50% for conventional spray guns.

Key Advantages of Electrostatic Spray Guns Over Traditional Painting Tools

1. Superior Transfer Efficiency

One of the most significant advantages of electrostatic spray guns is their exceptional transfer efficiency. Transfer efficiency refers to the percentage of paint that actually adheres to the target surface rather than becoming airborne or wasted.

- Electrostatic spray guns achieve transfer efficiencies of up to 90-95%, meaning nearly all the paint applied sticks to the object.

- Conventional spray guns typically have transfer efficiencies around 40-50%, resulting in substantial paint wastage.

This high efficiency translates into less paint consumption, lower material costs, and reduced environmental impact due to less volatile organic compound (VOC) emissions.

2. Enhanced Coating Quality and Coverage

Electrostatic spray guns produce a smooth, even finish that is difficult to replicate with traditional methods. The electrostatic charge causes paint particles to distribute evenly and wrap around objects, ensuring complete coverage.

- This is especially beneficial for complex shapes and tubular products where conventional spray guns may leave uncoated spots.

- The finish is not only more uniform but also more durable, with improved resistance to abrasion, corrosion, and environmental damage.

3. Reduced Overspray and Environmental Impact

Overspray is a common problem with traditional spray painting, where a large portion of paint misses the target and becomes airborne, creating health and environmental hazards.

- Electrostatic spray guns drastically reduce overspray by attracting paint particles directly to the grounded surface.

- This reduction in overspray lowers VOC emissions, which are harmful chemicals released during painting.

- Reduced VOCs contribute to better air quality and help facilities comply with environmental regulations such as COSHH and VOC emission standards.

4. Improved Operator Safety and Working Conditions

Because electrostatic spray guns minimize paint mist and overspray, they create a safer and cleaner working environment for operators.

- Less airborne paint means reduced risk of inhalation and exposure to harmful chemicals.

- Operators benefit from better visibility and less contamination, which also reduces cleanup time and costs.

5. Cost Savings and Return on Investment

Although electrostatic spray guns may have a higher upfront cost than conventional spray guns, their efficiency leads to significant long-term savings.

- Less paint consumption reduces material costs.

- Faster application times and less rework improve production throughput.

- Lower VOC emissions can reduce regulatory compliance costs and environmental fees.

- The combination of these factors results in a strong return on investment (ROI) for businesses adopting electrostatic technology.

Technical Considerations and Limitations

Addressing the Faraday Cage Effect

One challenge with electrostatic spraying is the Faraday cage effect, where paint particles are attracted to the nearest grounded surface, often coating edges but missing recessed or shadowed areas.

- To overcome this, painters may use a combination of electrostatic and conventional spray guns.

- Adjusting voltage and air pressure settings can also help direct paint into difficult areas.

Material Compatibility

Electrostatic spray guns work best with conductive materials because the electrostatic charge requires a grounded surface.

- For non-conductive materials like plastic or wood, a conductive primer may be necessary to optimize paint adhesion.

- Waterborne paints may require additional equipment such as isolation systems or external charging applicators.

Practical Applications of Electrostatic Spray Guns

Industrial and Commercial Use

Electrostatic spray guns are widely used in industries where high-quality finishes and efficiency are critical, such as automotive manufacturing, aerospace, furniture production, and metal fabrication.

- They are ideal for coating tubular parts, machinery, and complex assemblies.

- The technology is also favored in facilities aiming to reduce environmental impact and comply with strict VOC regulations.

Manual vs. Automated Electrostatic Spraying

Electrostatic spray guns can be used manually or integrated into automated painting systems.

- Manual electrostatic guns provide flexibility for small batches and touch-up work.

- Automated systems deliver consistent, high-volume coating for mass production.

Conclusion

Electrostatic spray guns represent a significant advancement over traditional painting tools by combining scientific principles with practical benefits. Their ability to charge paint particles and attract them magnetically to the target surface results in superior transfer efficiency, reduced waste, enhanced finish quality, and improved environmental and operator safety. While the initial investment may be higher, the long-term savings and performance gains make electrostatic spray guns a more efficient and cost-effective choice for many painting applications.

Frequently Asked Questions (FAQs)

Q1: What is transfer efficiency in painting, and why is it important?

A1: Transfer efficiency is the percentage of paint that adheres to the target surface during application. Higher transfer efficiency means less paint wastage, lower costs, and reduced environmental impact.

Q2: Can electrostatic spray guns be used on non-metal surfaces?

A2: Yes, but non-conductive surfaces like plastic or wood often require a conductive primer to enable the electrostatic effect for optimal paint adhesion.

Q3: How does electrostatic spraying reduce VOC emissions?

A3: By minimizing overspray and ensuring more paint reaches the surface, electrostatic spraying reduces the amount of volatile organic compounds released into the air.

Q4: What is the Faraday cage effect, and how does it affect electrostatic painting?

A4: The Faraday cage effect occurs when paint particles coat edges but fail to reach recessed areas due to electrostatic attraction. It can be mitigated by using conventional spray guns for those areas or adjusting spray parameters.

Q5: Are electrostatic spray guns more expensive than traditional spray guns?

A5: Electrostatic spray guns generally have a higher upfront cost but offer significant savings over time through reduced paint usage, faster application, and lower environmental compliance costs.

[1] https://elmbridgeuk.com/learning-hub/7-reasons-to-use-an-electrostatic-spray-gun/

[2] https://www.scribd.com/document/10317685/%E5%A4%A7%E5%AD%A6%E7%A7%91%E6%8A%80%E8%8B%B1%E8%AF%AD

[3] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/conventional-vs-electrostatic-spray-guns.html

[4] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/how-electrostatic-guns-can-benefit-your-facility.html

[5] https://indukote.ca/blog/benefits-of-electrostatic-painting-vs-traditional-painting/

[6] https://www.ultrimaxstore.com/blogs/news/the-advantages-of-electrostatic-spray-painting

[7] https://www.durr.com/en/media/news/news-detail/view/less-paint-consumption-new-electrostatic-spray-gun-for-a-more-efficient-painting-process-89612

[8] https://www.codinter.com/en/electrostatic-vs-conventional-painting-which-process-is-better/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.