Content Menu

● Understanding Electrostatic Spray Technology

>> What is an Electrostatic Spray Gun?

>> How Does an Automatic Electrostatic Spray Gun Work?

● Advantages of Using Automatic Electrostatic Spray Guns in Plants

>> Improved Transfer Efficiency Saves Material and Costs

>> Better Surface Coverage and Coating Quality

>> Reduced Volatile Organic Compound (VOC) Emissions

>> Enhanced Production Speeds and Automation Benefits

● Practical Considerations Before Investing

>> Cost of Equipment and Maintenance

>> The Faraday Cage Effect and Application Limitations

>> Compatibility With Materials and Environmental Conditions

● Economic and Environmental Impact Analysis

>> Material Savings and Cost Reduction

>> Reducing Environmental Impact and Regulatory Compliance

● Case Studies and Applications

>> Industrial Manufacturing

>> Agricultural Use

● Final Verdict: Is It Worth the Investment?

● Frequently Asked Questions (FAQs)

Electrostatic spraying technology has become a game changer in industrial and agricultural coating and spraying applications. As businesses and plants look to improve efficiency, cut costs, and reduce environmental impact, the question arises: Is investing in an automatic electrostatic spray gun really worth it for your plant? This article delves into the working principles, benefits, potential drawbacks, and financial considerations of adopting this innovative technology.

Understanding Electrostatic Spray Technology

What is an Electrostatic Spray Gun?

An electrostatic spray gun applies paint, coatings, pesticides, or other liquids by electrically charging the spray particles. These charged particles are then attracted to the oppositely charged target surface, which results in a uniform and efficient coating.

Traditional spray methods rely mostly on air pressure to atomize and direct spray, often leading to overspray and uneven coverage. In contrast, the electrostatic effect causes the particles to wrap around complex shapes and surfaces.

How Does an Automatic Electrostatic Spray Gun Work?

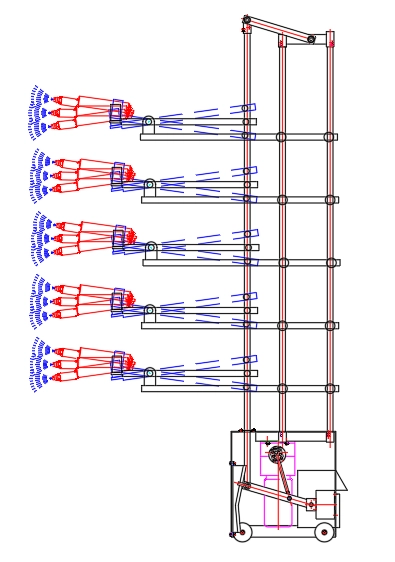

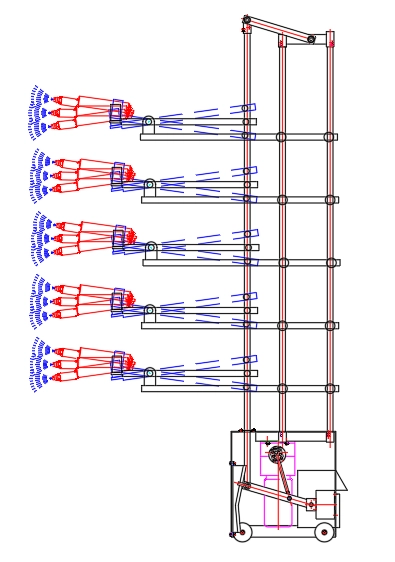

An automatic electrostatic spray gun integrates electrostatic technology with automation controls. This means the device operates through programmable controls that regulate spray parameters such as voltage, pressure, and spray duration. Typically, a Programmable Logic Controller (PLC) manages the system, allowing operators to achieve precision and repeatability in the spraying process.

Advantages of Using Automatic Electrostatic Spray Guns in Plants

Improved Transfer Efficiency Saves Material and Costs

One of the standout advantages is the high transfer efficiency—often over 90%—meaning most of the sprayed material ends up on the target surface rather than being lost to overspray. Traditional spray methods may have transfer efficiencies as low as 25-65%. This efficiency translates into material savings and reduces the need for frequent coating purchases.

Better Surface Coverage and Coating Quality

Electrostatically charged particles are drawn toward the substrate, enabling better coverage, especially on irregular or hard-to-reach surfaces. This wrapping effect reduces uncoated spots and offers a smoother, more consistent finish.

Reduced Volatile Organic Compound (VOC) Emissions

Because less coating material is wasted, fewer VOCs are emitted into the environment. This is especially crucial for plants needing to meet strict environmental regulations and aiming to reduce their carbon footprint.

Enhanced Production Speeds and Automation Benefits

Automatic electrostatic spray guns can be programmed for consistent spray patterns and rates, improving throughput while minimizing human error. Automated control systems also facilitate precise application, reducing rework and downtime.

Practical Considerations Before Investing

Cost of Equipment and Maintenance

Electrostatic spray systems generally involve a higher initial purchase price compared to conventional spray guns. Complete automatic setups with controllers and pumps typically range from several thousand to over ten thousand dollars. However, this upfront cost can be offset by long-term savings on materials and labor, providing a strong return on investment (ROI).

Maintenance costs include regular checks and upkeep of charging systems, pumps, and controllers. While these maintenance tasks are not significantly more complex than traditional spray equipment, they do require some specialized knowledge.

The Faraday Cage Effect and Application Limitations

Electrostatic spraying struggles with deep cavities or recessed corners due to the Faraday Cage Effect. The charged particles tend to accumulate on the outermost surfaces, making it difficult for the coating to reach into hidden or shadowed areas. This may require supplemental use of conventional spraying techniques to ensure full coverage.

Compatibility With Materials and Environmental Conditions

Electrostatic systems work best with conductive or semi-conductive materials. Spraying non-conductive substrates like certain plastics may need a conductive primer coat to maximize efficiency. Additionally, environmental factors such as humidity, temperature, and airflow can influence performance and must be considered during setup and operation.

Economic and Environmental Impact Analysis

Material Savings and Cost Reduction

Due to the higher transfer efficiency, plants can experience up to 20% or more savings in coating or paint materials compared to HVLP or air-assisted spray methods. The reduction in overspray also means less frequent filter changes in spray booths, reducing maintenance downtime and costs.

Reducing Environmental Impact and Regulatory Compliance

With lower VOC emissions, plants can more easily meet environmental standards and reduce their ecological footprint. This can also improve workplace air quality for employees, contributing to a safer working environment.

Case Studies and Applications

Industrial Manufacturing

Electrostatic spray guns are widely used in automotive, appliance, and metal fabrication industries. The precise application reduces material costs and improves the finish quality, essential for maintaining high standards in production.

Agricultural Use

Automatic electrostatic sprayers have been designed for agricultural applications to enhance pesticide deposition on crops, increasing efficacy while minimizing chemical waste. The ability to precisely control spray volumes and coverage makes these systems invaluable for modern farming practices.

Final Verdict: Is It Worth the Investment?

The decision to invest in an automatic electrostatic spray gun depends on multiple factors:

- Scale of operations and volume of spraying required

- Types of materials or coatings used

- Substrate shapes and complexity

- Environmental regulations and sustainability goals

- Capital availability and cost-benefit timelines

For plants dealing with large volumes, complex shapes, or stringent material cost controls, the advantages of automatic electrostatic spraying offer compelling value. The technology's ability to improve coating efficiency, reduce waste, and speed production provides a strong case for adoption.

Plants with simpler needs or budget constraints might find conventional spraying sufficient but could consider electrostatic systems as a future upgrade.

Frequently Asked Questions (FAQs)

1. What kind of materials can be sprayed using electrostatic spray guns?

Electrostatic spray guns can handle paints, coatings, pesticides, and herbicides. They work best with conductive materials but can be adapted for non-conductive substrates using primers.

2. How much can I expect to save on paint or coating materials?

Savings vary but typically range from 20% to over 50% compared to conventional spraying methods due to higher transfer efficiency.

3. Are there environmental benefits to using electrostatic spray guns?

Yes, they reduce VOC emissions and overspray waste, contributing to better air quality and regulatory compliance.

4. Does electrostatic spraying require special training to operate?

Operators need training on safety and system controls, especially to handle high-voltage components and ensure proper spray settings.

5. Can an electrostatic spray gun reach difficult areas and corners?

There are limitations due to the Faraday Cage Effect, which can prevent coating on recessed areas. Supplemental conventional spraying may be needed for full coverage.

[1] https://www.cetinc.com/should-i-be-using-electrostatic-spray/

[2] https://pdfs.semanticscholar.org/1522/1b278d1e06014c7b275e0beaa10a43ee28f7.pdf

[3] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/advantages-of-spraying-with-electrostatic-guns.html

[4] https://www.alibaba.com/showroom/electrostatic-spray-gun-price.html

[5] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/conventional-vs-electrostatic-spray-guns.html

[6] https://patents.google.com/patent/CN1006447B/zh

[7] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/electrostatic-spray-gun-frequently-asked-questions-faqs

[8] https://pubchem.ncbi.nlm.nih.gov/patent/CN-213669935-U

[9] https://www.youtube.com/watch?v=OYQpxpHvDjE

[10] https://patents.google.com/patent/CN101351273B/en

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.