Content Menu

● Understanding Electrostatic Powder Coating

>> What is Electrostatic Powder Coating?

>> Advantages of Electrostatic Spray Guns

● Top Electrostatic Spray Guns for Industrial Powder Coating in 2025

>> 1. Nordson Encore® Automatic Powder Coating Guns

>>> Key Features

>>> Benefits

>> 2. Gema OptiGun® Automatic Gun

>>> Key Features

>>> Benefits

>> 3. Dezhou Aohai AH-S500 Manual Electrostatic Powder Coating Spray Gun

>>> Key Features

>>> Benefits

● How to Choose the Right Electrostatic Spray Gun

>> Consider Your Application Needs

>> Transfer Efficiency and Voltage

>> Maintenance and Cleaning

● Latest Technological Trends in 2025 Electrostatic Spray Guns

>> Intelligent Control Systems

>> Enhanced Powder Delivery

>> Environmental Compliance

● Installation and Safety Considerations

>> Grounding and Electrical Safety

>> Operator Training

● Maintenance Tips for Longevity and Performance

● Frequently Asked Questions (FAQs)

Industrial powder coating continues to be a cornerstone technology for durable, high-quality finishes on metal and other substrates. Electrostatic spray guns, which use charged particles to improve coating efficiency and finish quality, are at the forefront of this technology. As we move through 2025, advancements in electrostatic spray guns offer manufacturers enhanced precision, efficiency, and ease of use. This article explores the best electrostatic spray guns available in 2025 for industrial powder coating, highlighting their features, benefits, and applications.

Understanding Electrostatic Powder Coating

What is Electrostatic Powder Coating?

Electrostatic powder coating involves applying a dry powder to a substrate using an electrostatic charge. The powder particles are electrically charged as they exit the spray gun and are attracted to the grounded workpiece. This method ensures a more uniform coating, reduces overspray, and improves transfer efficiency compared to traditional liquid painting methods.

Advantages of Electrostatic Spray Guns

- Higher Transfer Efficiency: More powder adheres to the part, reducing waste.

- Improved Coating Quality: Uniform coverage with fewer defects.

- Environmental Benefits: Less volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) released.

- Cost Savings: Reduced powder consumption and faster application processes.

Top Electrostatic Spray Guns for Industrial Powder Coating in 2025

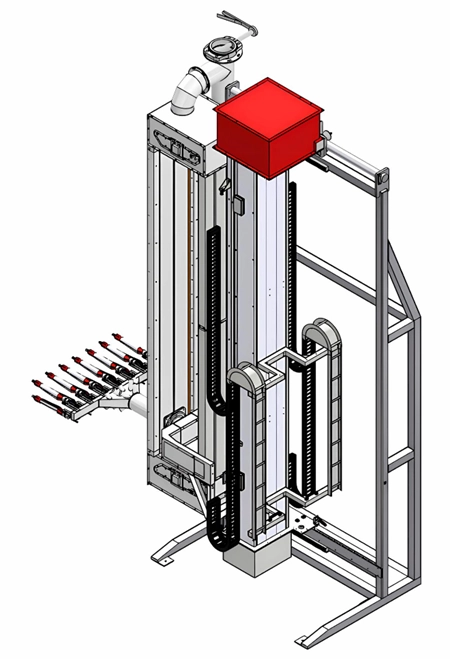

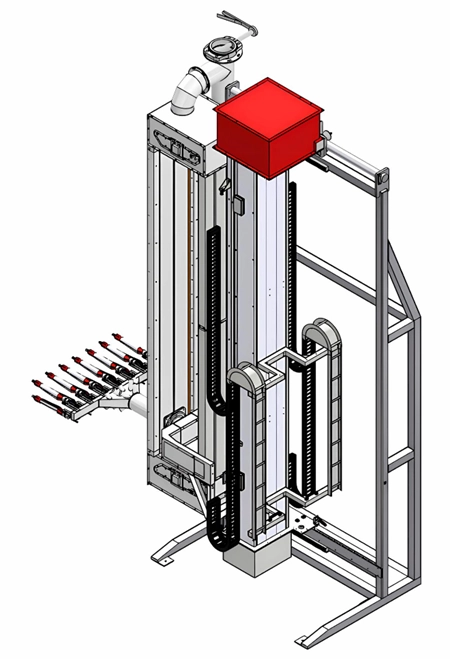

1. Nordson Encore® Automatic Powder Coating Guns

Nordson's Encore® series is renowned for its reliability and robust design. These guns produce up to 100 kV of electrostatic charge, delivering one of the highest transfer efficiencies on the market. The Encore® guns utilize Select Charge® technology, which ensures superior coating coverage and efficiency.

Key Features

- Lightweight and compact design for ease of use.

- Automatic Feedback Current (AFC) control for consistent transfer efficiency.

- Air-purge cleanable design allows quick cleaning without disassembly.

- Adjustable mounting brackets for versatile positioning.

- Specially engineered materials reduce wear and impact fusion.

- Optional ion collector device enhances finish appearance.

Benefits

The Encore® guns are ideal for high-volume industrial painting environments requiring fast color changes and superior finish quality. Their ergonomic design and easy maintenance make them a favorite among finishing professionals.

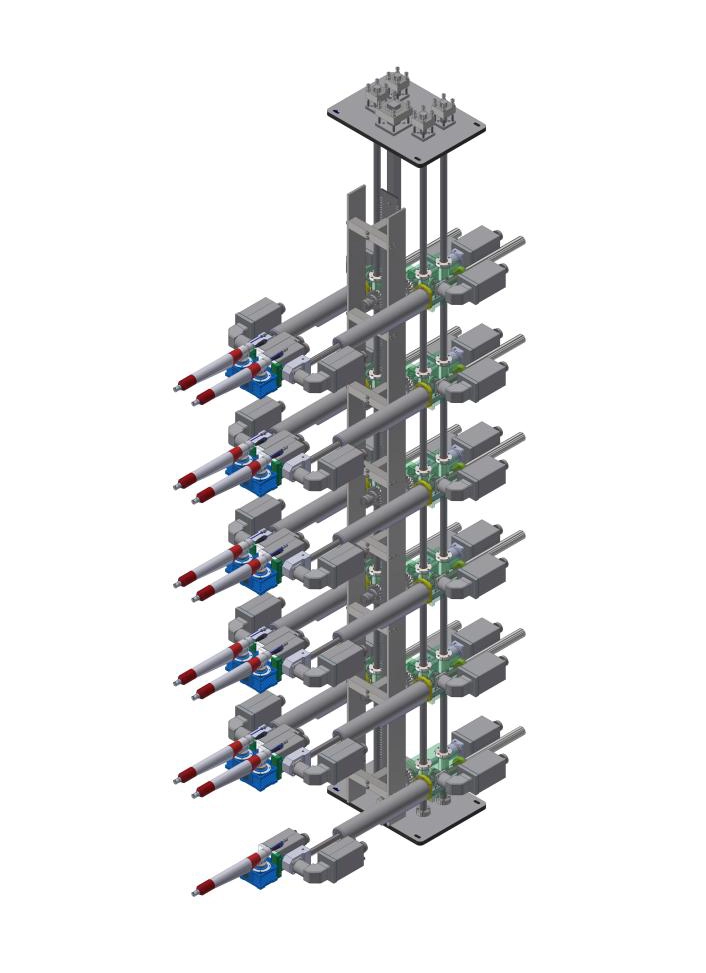

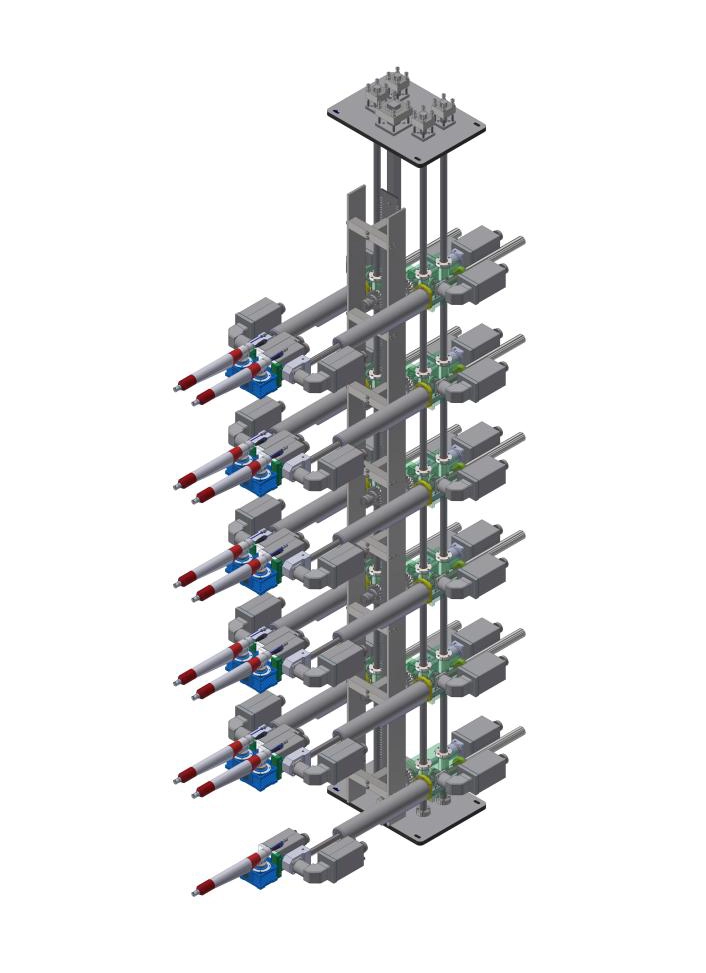

2. Gema OptiGun® Automatic Gun

Gema's OptiGun® is a robust automatic electrostatic spray gun featuring industry-leading PowerBoost® technology. This gun is designed for reliability and high-quality coating results across various industrial applications.

Key Features

- PowerBoost® high-performance technology for consistent voltage.

- OptiSpray All-in-One application pump technology for efficient powder management.

- Dynamic Contour Detection system for precise coating of complex shapes.

- Easy integration into automated production lines.

- Fast and efficient color change capabilities.

Benefits

The OptiGun® excels in coating complex parts with high precision and minimal powder waste. Its advanced automation capabilities make it suitable for manufacturers seeking to improve throughput and reduce manual intervention.

3. Dezhou Aohai AH-S500 Manual Electrostatic Powder Coating Spray Gun

For applications requiring manual operation, the AH-S500 from Dezhou Aohai offers an advanced solution with ergonomic design and intelligent control features.

Key Features

- Voltage output adjustable up to 100 kV.

- Built-in electrostatic injection molding technology compatible with imported parts.

- Ultra-high efficiency powder pump ensures uniform powder transmission.

- Intelligent voltage and current adjustment for complex shapes.

- Spray mode memory storage for consistent application.

- Lightweight (480g) and comfortable for handheld use.

Benefits

The AH-S500 is well-suited for smaller operations or touch-up work where manual precision is required. Its intelligent features reduce operator fatigue and improve coating consistency, making it a competitive choice for manual powder coating tasks.

How to Choose the Right Electrostatic Spray Gun

Consider Your Application Needs

- Volume of Production: Automatic guns like the Nordson Encore® and Gema OptiGun® are better for high-volume, automated lines.

- Part Complexity: Guns with contour detection and adjustable positioning handle complex shapes better.

- Manual vs. Automatic: Manual guns offer flexibility for small batches or repairs, while automatic guns improve speed and consistency in mass production.

Transfer Efficiency and Voltage

Higher voltage output (up to 100 kV) generally means better transfer efficiency, reducing powder waste and improving finish quality.

Maintenance and Cleaning

Look for guns with air-purge designs or easy disassembly to minimize downtime during color changes or maintenance.

Latest Technological Trends in 2025 Electrostatic Spray Guns

Intelligent Control Systems

Modern guns incorporate smart sensors and memory functions that adjust voltage and current automatically based on the shape and size of the workpiece.

Enhanced Powder Delivery

Advanced powder pumps and injection molding technologies ensure uniform powder flow, reducing clogging and overspray.

Environmental Compliance

Newer models focus on reducing VOC emissions and powder waste, helping manufacturers meet stricter environmental regulations.

Installation and Safety Considerations

Grounding and Electrical Safety

Proper grounding of the spray gun and workpiece is critical to avoid electrical hazards and maximize transfer efficiency.

Operator Training

Effective use of electrostatic spray guns requires trained operators who understand the equipment and safety protocols.

Maintenance Tips for Longevity and Performance

- Regularly clean powder pathways and nozzles.

- Inspect and replace worn parts promptly.

- Use air-purge features to reduce downtime.

- Calibrate voltage and current settings according to manufacturer recommendations.

Frequently Asked Questions (FAQs)

Q1: What is the maximum voltage output for industrial electrostatic spray guns in 2025?

A1: Most advanced industrial electrostatic spray guns, such as Nordson Encore® and Dezhou Aohai AH-S500, offer voltage outputs up to 100 kV to maximize transfer efficiency.

Q2: Can electrostatic spray guns be used for both manual and automatic powder coating?

A2: Yes, there are models designed specifically for manual operation and others optimized for automatic, high-volume production lines.

Q3: How does electrostatic powder coating reduce environmental impact?

A3: It reduces powder waste and VOC emissions by improving transfer efficiency, leading to less overspray and fewer hazardous emissions.

Q4: What maintenance is required for electrostatic spray guns?

A4: Regular cleaning of powder pathways, air-purge cleaning, and inspection of wear parts are essential to maintain performance.

Q5: Are there electrostatic spray guns suitable for complex-shaped parts?

A5: Yes, guns like the Gema OptiGun® feature contour detection and adjustable positioning to coat complex geometries effectively.

[1] https://www.nordson.com/en/products/industrial-coating-systems-products/automatic-powder-coating-guns

[2] https://www.made-in-china.com/manufacturers/electrostatic-spray-gun.html

[3] https://www.gemapowdercoating.com/en/home-north-america

[4] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/electrostatic-spray-gun-basics.html

[5] https://aohaicoasting.en.made-in-china.com/product/QEoRxqJdaBYw/China-Factory-Price-2025-Manual-Operation-Electrostatic-Powder-Coating-Spray-Gun-for-New-Starter-Test.html

[6] https://patents.google.com/patent/CN101014415A/zh

[7] https://www.youtube.com/watch?v=gAXx_O8ZVFo

[8] https://patents.google.com/patent/CN1171684C/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.