Content Menu

● Introduction

● What is a Personalized Manual Spray Booth System?

● Why Choose a Personalized Manual Spray Booth System?

>> H2: Customization to Fit Your Unique Needs

>> H3: Enhanced Safety and Environmental Compliance

>> H3: Cost-Effectiveness and Efficiency

● Key Features of a Personalized Manual Spray Booth System

>> H2: Manual Operation with Precision Control

>> H3: Advanced Filtration Technology

>> H3: Flexible Configuration Options

● Applications of Personalized Manual Spray Booth Systems

>> H2: Automotive and Aerospace Industries

>> H2: Furniture and Industrial Equipment

>> H2: Powder Coating and Specialty Coatings

● How to Choose the Right Personalized Manual Spray Booth System

>> H2: Assess Your Production Needs

>> H3: Evaluate Space and Ventilation Requirements

>> H3: Consult with Experienced Manufacturers

● Maintenance and Operational Tips for Personalized Manual Spray Booth Systems

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

In the evolving world of surface finishing and coating, the demand for tailored solutions has never been higher. A Personalized Manual Spray Booth System offers manufacturers, brand owners, and wholesalers a unique advantage by delivering customizable, efficient, and safe environments for spray coating processes. This article explores the benefits, features, and applications of such systems, emphasizing their role in enhancing productivity and quality in various industries.

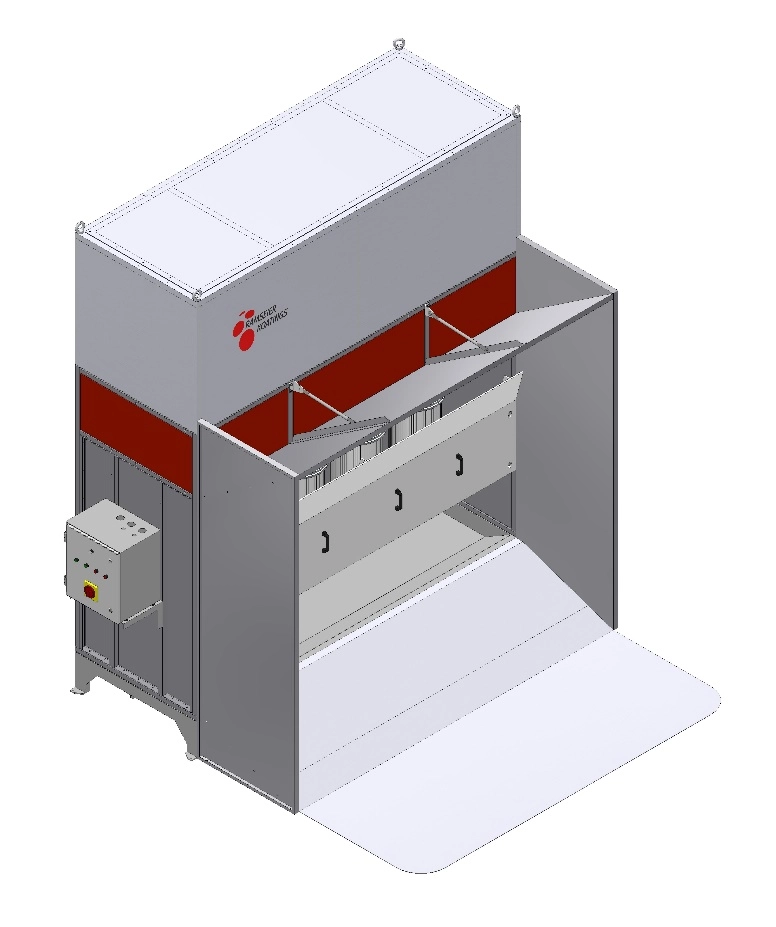

What is a Personalized Manual Spray Booth System?

A Personalized Manual Spray Booth System is a custom-designed spray booth tailored to the specific needs of a user or business. Unlike standard booths, these systems are manually operated and can be adapted in size, ventilation, filtration, and configuration to meet unique production requirements. They provide a controlled environment to contain overspray, reduce contamination, and protect operators and the environment during spray painting or coating operations.

Why Choose a Personalized Manual Spray Booth System?

H2: Customization to Fit Your Unique Needs

Every coating project has distinct requirements based on the size of parts, type of coating, and workspace limitations. A Personalized Manual Spray Booth System allows for:

- Adjustable dimensions to fit available floor space or specific product sizes.

- Custom ventilation and filtration tailored to the coating materials used.

- Integration of lighting and safety features based on operational needs.

This level of customization ensures optimal working conditions and superior finish quality.

H3: Enhanced Safety and Environmental Compliance

Spray booths are critical to maintaining safe working environments by controlling hazardous fumes and particles. A personalized system can be engineered to comply with local and international environmental regulations, ensuring:

- Proper containment of volatile organic compounds (VOCs).

- Efficient air filtration and exhaust systems.

- Safe operator exposure levels.

H3: Cost-Effectiveness and Efficiency

By designing a booth specifically for your process, you avoid paying for unnecessary features and maximize resource use. A Personalized Manual Spray Booth System can reduce:

- Material waste through better overspray control.

- Energy consumption with optimized airflow and lighting.

- Downtime by facilitating easier cleaning and maintenance.

Key Features of a Personalized Manual Spray Booth System

H2: Manual Operation with Precision Control

Manual spray booths allow operators to control the spray application directly, which is ideal for small to medium production runs or specialized finishes. Features include:

- Ergonomic design for operator comfort.

- Adjustable spray zones and airflow.

- Easy access for maintenance and cleaning.

H3: Advanced Filtration Technology

To ensure a clean working environment, these booths incorporate multi-stage filters that capture overspray and particulates effectively, protecting both the operator and the environment.

H3: Flexible Configuration Options

Depending on the application, booths can be configured with:

- Water curtain or dry filter systems.

- Explosion-proof lighting and electrical components.

- Optional powder coating compatibility.

Applications of Personalized Manual Spray Booth Systems

H2: Automotive and Aerospace Industries

These sectors require precise, high-quality finishes on parts ranging from small components to large panels. A personalized system ensures consistent coating thickness and finish quality while maintaining compliance with strict environmental standards.

H2: Furniture and Industrial Equipment

Custom spray booths accommodate varied sizes and shapes of furniture and machinery parts, improving finish durability and appearance.

H2: Powder Coating and Specialty Coatings

Manual booths can be adapted for powder coating processes, providing a contained environment that improves powder recovery and reduces contamination.

How to Choose the Right Personalized Manual Spray Booth System

H2: Assess Your Production Needs

Consider the size and volume of parts, types of coatings, and operator workflow.

H3: Evaluate Space and Ventilation Requirements

Ensure the booth fits your workspace and meets ventilation standards for safety.

H3: Consult with Experienced Manufacturers

Partner with OEM providers who understand your industry and can deliver tailored solutions with ongoing support.

Maintenance and Operational Tips for Personalized Manual Spray Booth Systems

- Regularly replace filters to maintain airflow and filtration efficiency.

- Clean spray booth surfaces to prevent contamination.

- Schedule periodic inspections for ventilation and electrical systems.

- Train operators on safe and effective booth usage.

Frequently Asked Questions (FAQs)

Q1: What advantages does a personalized manual spray booth system offer over standard booths?

A1: It provides tailored dimensions, ventilation, and features to match specific production needs, improving efficiency, safety, and finish quality.

Q2: Can a personalized manual spray booth system handle different types of coatings?

A2: Yes, these systems can be customized for various coatings including liquid paints, powder coatings, and specialty finishes.

Q3: How does a manual spray booth system ensure operator safety?

A3: By incorporating effective ventilation, filtration, and containment measures, it minimizes exposure to hazardous fumes and particulates.

Q4: What maintenance is required for a personalized manual spray booth?

A4: Regular filter changes, cleaning, and system inspections are essential to maintain optimal performance and safety.

Q5: How do I select the right OEM partner for a personalized manual spray booth system?

A5: Choose a manufacturer with proven experience, customization capabilities, quality certifications, and good after-sales support.

Conclusion

A Personalized Manual Spray Booth System is a vital investment for businesses seeking to enhance their coating operations with tailored solutions that improve safety, efficiency, and finish quality. By working with experienced OEM manufacturers, companies can achieve customized spray environments that meet their unique production demands and regulatory requirements.

[1] https://www.spraysystems.com

[2] https://www.hppneumatics.com/spray-booths/

[3] https://relyonusa.com/services/custom-spray-booths/

[4] https://www.rohnerspraybooths.com/paint-booths/

[5] https://www.paint-booths.com/custom-paint-booths.html

[6] https://patents.google.com/patent/CN107497620A/zh

[7] https://antspraybooth.en.made-in-china.com/product/bnmRMIFlhirj/China-Customized-Manual-Electrostatic-Powder-Coating-Spray-Booth.html

[8] https://patents.google.com/patent/CN219560066U/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.