Content Menu

● Introduction

● What is a Custom Manual Spray Booth System?

>> Key Components

● Advantages of Custom Manual Spray Booth Systems

>> Precision and Flexibility

>> Customization for Unique Needs

>> Cost-Effectiveness

>> Enhanced Safety and Compliance

● Essential Features to Look For

>> Effective Ventilation System

>> Advanced Filtration

>> Superior Lighting

>> User-Friendly Controls

>> Robust Safety Systems

● Customization Options for International OEMs and Brands

>> Size and Layout

>> Airflow Patterns

>> Specialized Filtration

>> Integration with Existing Lines

>> Branding and Aesthetics

● Maintenance and Best Practices

>> Routine Maintenance

>> Operator Training

>> Regulatory Compliance

● Comparing Manual vs. Modular Spray Booths

● Applications Across Industries

● Frequently Asked Questions

● Citations:

Introduction

In the rapidly evolving world of industrial finishing, the Custom Manual Spray Booth System stands out as an essential solution for businesses seeking precision, flexibility, and superior coating quality. Whether you are an OEM, a brand owner, a wholesaler, or a manufacturer catering to international markets, understanding the advantages and technical nuances of custom manual spray booths is crucial for maintaining a competitive edge. This comprehensive guide explores the features, benefits, customization options, and best practices for integrating a custom manual spray booth system into your production line, ensuring both operational efficiency and compliance with global standards.

---

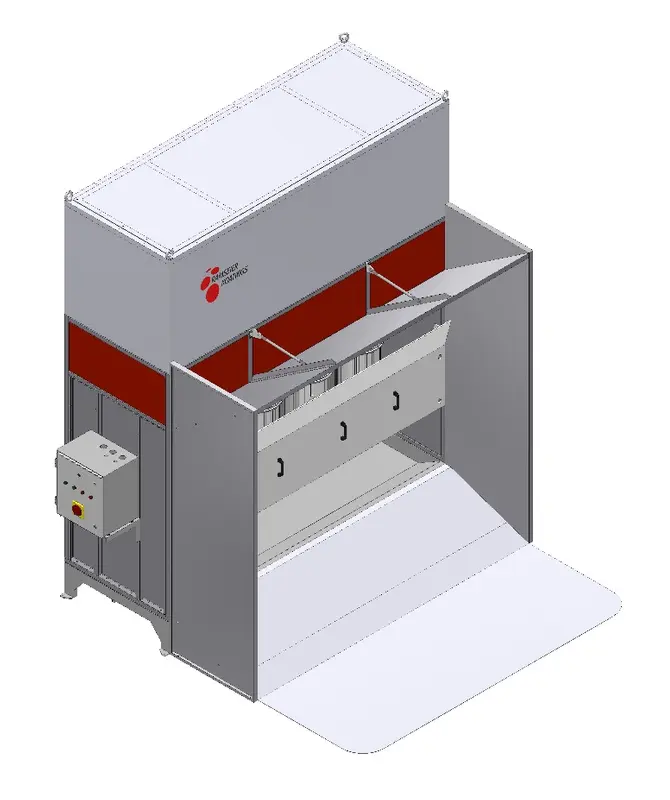

What is a Custom Manual Spray Booth System?

A Custom Manual Spray Booth System is a specialized enclosure designed for the manual application of paints, coatings, or finishes to various products. Unlike automated spray booths, these systems are operated by skilled technicians who control the spray equipment, allowing for greater adaptability and precision-especially valuable for low-volume, complex, or highly detailed projects[1].

Key Components

- Enclosure: Provides a controlled environment to prevent contamination.

- Ventilation and Filtration: Removes overspray, fumes, and airborne particles for safety and quality.

- Lighting: Ensures optimal visibility for accurate application.

- Control Panel: Allows operators to manage airflow, lighting, and other parameters[2].

- Safety Features: Includes fire suppression, explosion-proof fixtures, and emergency stops.

---

Advantages of Custom Manual Spray Booth Systems

Precision and Flexibility

Manual spray booths offer unmatched control, making them ideal for applications that demand high-quality finishes or involve intricate parts. Operators can adjust techniques in real-time, ensuring consistent results across diverse product types[1].

Customization for Unique Needs

Every industry and product has distinct coating requirements. Custom manual spray booth systems can be tailored in size, airflow design, filtration, and safety features to meet specific operational and regulatory demands[4][11].

Cost-Effectiveness

Compared to fully automated systems, manual spray booths typically have lower upfront costs and are easier to maintain. Modular and custom designs also allow for future expansion or relocation, providing long-term value[3][5].

Enhanced Safety and Compliance

A well-designed spray booth system helps control hazardous materials, maintain air quality, and comply with OSHA, NFPA, and EPA standards, reducing the risk of workplace incidents and regulatory penalties[11][12].

---

Essential Features to Look For

Effective Ventilation System

Proper airflow is critical for removing hazardous fumes and overspray, protecting both operators and products. Look for booths with adjustable fans and high-capacity exhaust systems[2][7].

Advanced Filtration

High-efficiency filters capture particulates and ensure clean air is recirculated or safely exhausted. Cartridge recovery systems are especially effective for powder coating applications[5].

Superior Lighting

Bright, shadow-free lighting enables precise application and inspection of finishes, reducing the risk of defects[2].

User-Friendly Controls

Intuitive control panels allow operators to preset parameters such as airflow, temperature, and spray patterns, boosting productivity and consistency[1][2].

Robust Safety Systems

Explosion-proof lighting, fire suppression, and emergency shutoffs are essential for safe operation, especially when handling flammable materials[2][12].

---

Customization Options for International OEMs and Brands

Size and Layout

Custom manual spray booth systems can be designed to fit any workspace, from compact batch booths to large conveyorized lines. Modular designs facilitate easy installation and future scalability[3][5].

Airflow Patterns

Choose from crossdraft, downdraft, or side-draft configurations based on the required finish quality and product type. Downdraft booths, for example, offer superior overspray removal for high-end finishes[7][9].

Specialized Filtration

Select filter types and recovery systems based on the coating material-liquid, powder, or multi-coat operations-to optimize both performance and compliance[5][9].

Integration with Existing Lines

Custom booths can be engineered to integrate seamlessly with conveyors, robotic arms, or manual workstations, enhancing workflow efficiency[4][5].

Branding and Aesthetics

For international OEMs and brand owners, booth exteriors can be customized with logos, colors, and finishes to reinforce corporate identity.

---

Maintenance and Best Practices

Routine Maintenance

- Weekly: Check and replace exhaust filters, clean floors, and inspect lighting[8].

- Quarterly: Inspect and replace intake filters, clean air chambers, and check compressed air filters[8].

- Semi-Annually: Deep clean all components, inspect safety systems, and recalibrate controls.

Operator Training

Proper training ensures safe operation, optimal results, and extended equipment lifespan. Operators should be familiar with PPE requirements, spray gun settings, and emergency procedures[7].

Regulatory Compliance

Adhering to local and international safety codes (OSHA, NFPA, ATEX) is essential for legal operation and export eligibility[11][12].

---

Comparing Manual vs. Modular Spray Booths

| Feature | Custom Manual Spray Booth System | Modular Spray Booth System |

| Installation | Tailored to site, may take longer | Fast, off-site assembly |

| Customization | High (size, airflow, features) | Moderate to high |

| Scalability | Custom expansion possible | Easily scalable/relocatable |

| Upfront Cost | Moderate | Often lower |

| Maintenance | Simple, part replacement | Easy, panel-based |

| Compliance | Designed to meet standards | Often pre-certified |

---

Applications Across Industries

- Automotive: Precision painting for parts and custom vehicles.

- Furniture: High-quality finishes on wood and metal pieces.

- Aerospace: Coating complex assemblies with strict quality controls.

- Electronics: Protective and decorative coatings for casings.

- OEM Manufacturing: Flexible solutions for diverse product lines.

---

Frequently Asked Questions

Q1: What makes a custom manual spray booth system ideal for OEMs and international brands?

A1: Its adaptability, precision, and ability to be tailored for specific products and regulatory requirements make it ideal for diverse and evolving production needs[1][4][11].

Q2: How do I choose the right size and configuration for my spray booth?

A2: Assess your product dimensions, production volume, available space, and required finish quality. Consult with a supplier who can design a system based on these factors[4][5].

Q3: What are the key safety features to include?

A3: Explosion-proof lighting, fire suppression systems, emergency stops, and compliant ventilation/filtration are essential for safe operation[2][12].

Q4: How often should maintenance be performed?

A4: Follow a schedule of weekly, quarterly, and semi-annual checks, focusing on filters, airflow, safety systems, and cleanliness to ensure optimal performance[8].

Q5: Can a custom manual spray booth system be integrated with automated lines?

A5: Yes, custom booths can be engineered for seamless integration with conveyors, robotics, or manual workstations, enhancing workflow and flexibility[4][5].

---

Citations:

[1] https://www.ramseierkoatings.com/news/Best-Manual-Spray-Booth-Features.html

[2] https://www.ramseierkoatings.com/what-are-the-top-features-to-look-for-in-a-manual-spray-booth-system.html

[3] https://www.paintbooth.com/what-are-the-pros-and-cons-of-modular-paint-booths/

[4] https://www.hppneumatics.com/spray-booths/

[5] https://www.nordson.com/en/products/industrial-coating-systems-products/manual-powder-coating-booth

[6] https://globalfinishing.com/2011/02/24/paint-booth-faqs-part-1/

[7] https://www.codinter.com/en/spray-booths-a-complete-guide/

[8] https://www.finishsystems.com/blogs/news/what-maintenance-do-you-recommend-for-our-spray-booth

[9] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-coatings-involved-in-the-finishing-process/

[10] https://www.paint-booths.com/FAQS.html

[11] https://www.hppneumatics.com/spray-booth-benefits/

[12] https://globalfinishing.com/2011/03/31/paint-booth-faqs-part-ii/

[13] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-coatings-involved-in-the-finishing-process/

[14] https://www.spraysystems.com/spray-booth-lighting-a-guide-to-finish-quality-safety-and-operational-costs/

[15] https://globalfinishing.com/2019/09/26/custom-paint-booths-what-to-look-for-beyond-the-equipment-specs-price/

[16] https://relyonusa.com/6h-rule-compliance-for-spray-booths/

[17] https://pfsspraybooths.com/custom-paint-booth-tailored-solutions-for-your-unique-needs

[18] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[19] https://pfsspraybooths.com/the-ultimate-paint-booth-usage-guide-for-perfect-results

[20] https://www.ramseierkoatings.com/news/Advantages-of-Manual-Spray-Booths-Over-Automation.html

[21] https://jmcautomotiveequipment.com/automotive-paint-booth-equipment/automotive-spray-booth/

[22] https://www.ramseierkoatings.com/manual-spray-booth-system-distributor-the-ultimate-guide-for-industrial-coating-solutions.html

[23] https://gsbindustries.com/the-evolution-of-paint-booth-technology/

[24] https://www.scribd.com/document/753572775/Spray-Booth-Technology-A-Comprehensive-Guide

[25] https://rttsolutions.com/wp-content/uploads/2020/09/Spray-Booth-Manual-2020.pdf

[26] https://gsbindustries.com/paint-booth-design-and-functionality/

[27] https://www.rohnerspraybooths.com/blog/benefits-of-custom-paint-booth

[28] https://marathonspraybooths.com

[29] https://www.johnbakersales.com/service/

[30] https://www.codinter.com/en/spray-booths-a-complete-guide/

[31] https://globalfinishing.com/2019/06/12/understanding-key-components-of-paint-booth-design/

[32] https://alliedcleanrooms.com/paint-booths-types-and-benefits/

[33] https://productionsystems-usa.com

[34] https://www.rohnerspraybooths.com

[35] https://www.youtube.com/watch?v=Pav4BD0gUcw&ab_channel=Media1WrapThis

[36] https://giffininc.com/products-systems/spraybooths/

[37] https://www.spraysystems.com/questions-to-address-when-purchasing-a-spray-booth/

[38] https://www.usius.com/essential-questions-to-ask-your-paint-booth-supplier/

[39] https://360zolutions.com/need-spraybooth-questions-to-answer/

[40] https://www.youtube.com/watch?v=IQodfZvcX7Y

[41] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/a-complete-guide-to-keeping-a-paint-booth-clean

[42] https://globalfinishing.com/2011/11/15/your-questions-answered-part-1/

[43] https://woodweb.com/cgi-bin/forums/finishing.pl?read=852919

[44] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/common-paint-booth-problems-and-how-to-fix-them

[45] https://pfsspraybooths.com/importance-of-regular-maintenance-for-spray-paint-booths

[46] https://forum.finescale.com/t/spray-booth-questions/199272

[47] https://www.spraysystems.com/nfpa-33-a-guide-to-fire-safety-compliance-for-paint-spray-booths/

[48] https://www.spraysystems.com/nfpa-33/

[49] https://www.asminternational.org/tss/wp-content/uploads/sites/38/files/content/safety5.pdf

[50] https://www.spraysystems.com

[51] https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=2000NT9X.TXT

[52] https://www.purchasing.com/automotive/spray-paint-booths/purchasing-guide/index.html

[53] https://www.spraysystems.com/news-blog/

[54] https://www.ramseierkoatings.com/what-is-the-best-manual-spray-booth-system-for-small-batch-production.html

[55] https://www.duroair.com/blog/questions-qualifying-industrial-paint-booth-manufacturers

[56] https://p2infohouse.org/ref/30/29081.pdf

[57] https://globalfinishing.com/wp-content/uploads/2022/01/General_Purpose_Downdraft_Service_and_Maintenance_Manual.pdf

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.