Content Menu

● How Automatic Electrostatic Spray Guns Work

● Industries Benefiting from Automatic Electrostatic Spray Guns

>> Automotive Industry

>> Aerospace Industry

>> Furniture Manufacturing

>> Marine Industry

>> Manufacturing and Industrial Equipment

>> Medical Equipment Industry

>> Electronics and Electrical Equipment

>> Construction and Infrastructure

>> Consumer Appliances and Retail Fixtures

>> Sporting Goods and Bicycles

● Advantages of Automatic Electrostatic Spray Guns Across Industries

● Future Trends and Market Outlook

● Common Questions and Answers

>> 1. What makes electrostatic spray guns more efficient than conventional spray guns?

>> 2. Can electrostatic spray guns be used on non-metal surfaces?

>> 3. Are electrostatic spray guns environmentally friendly?

>> 4. What types of coatings can be applied using automatic electrostatic spray guns?

>> 5. How does automation enhance the use of electrostatic spray guns?

Automatic electrostatic spray guns are advanced coating tools that use electrostatic charge to ensure uniform application of paints, coatings, or other fluids onto surfaces. This technology offers high transfer efficiency, reducing overspray and material waste, while providing superior finish quality. Various industries utilize automatic electrostatic spray guns to enhance product durability, aesthetics, and production efficiency. This article explores the industries that benefit the most from this technology, examining how it improves processes and outcomes in each sector.

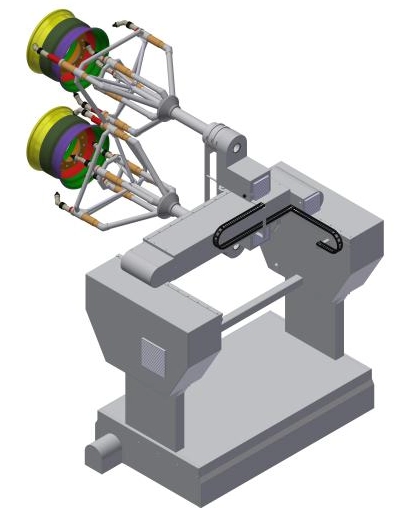

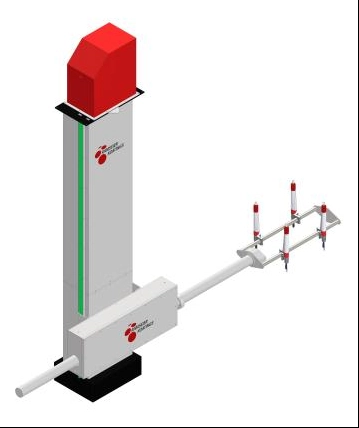

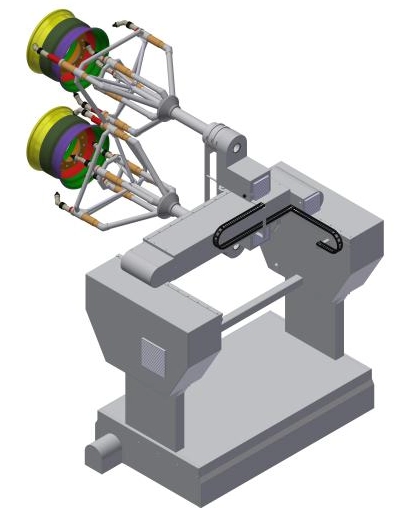

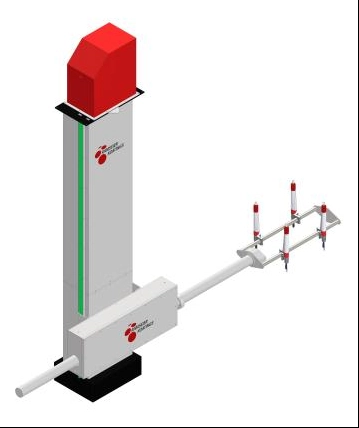

How Automatic Electrostatic Spray Guns Work

Automatic electrostatic spray guns operate by charging the paint particles electrically as they are sprayed toward a grounded target surface. Because opposite charges attract, the paint particles wrap around the object, providing an even and complete coating—even on complex geometries. This wraparound effect significantly reduces paint wastage and VOC (volatile organic compound) emissions, making it an environmentally friendly and cost-effective solution.

Industries Benefiting from Automatic Electrostatic Spray Guns

Automotive Industry

The automotive sector is one of the largest users of automatic electrostatic spray guns. Cars, trucks, buses, and motorcycles require coatings that offer aesthetic appeal, corrosion resistance, and durability. Electrostatic spray technology ensures:

- Uniform coverage on intricate and curved surfaces.

- Superior adhesion that protects metal parts from rust and wear.

- Reduced overspray and paint waste, lowering production costs.

- Faster drying times due to efficient paint particle transfer.

This technology helps manufacturers achieve high-quality finishes with minimal environmental impact and improved production efficiency.

Aerospace Industry

Aerospace components, including airplanes, helicopters, and satellites, demand coatings that can withstand harsh environments, such as high altitude conditions and temperature fluctuations. The precise, consistent coating application of electrostatic spray guns provides:

- Enhanced protection against corrosion and wear.

- Uniform coating on complex components like turbine blades and fuselage parts.

- Improved performance and longevity of aerospace equipment.

- Compliance with strict regulations governing aerospace manufacturing.

Electrostatic coating is critical in ensuring that aircraft meet safety and durability standards while maintaining lightweight structures.

Furniture Manufacturing

Furniture finishing benefits greatly from electrostatic spray technology. Wooden and metal furniture pieces often have complex shapes with hard-to-reach areas. Electrostatic spray guns enable:

- Even coating on all surfaces, including inside corners and recesses.

- High-quality, smooth finishes that enhance appearance.

- Reduced paint consumption and environmental impact.

- Faster production cycles with automated application.

This ensures that furniture has a consistent protective and decorative finish that lasts.

Marine Industry

Ships, boats, and yachts require coatings that resist saltwater corrosion, UV damage, and mechanical wear. Electrostatic spray guns provide:

- Uniform and thick coating layers that protect against harsh marine conditions.

- Efficient application on large and irregularly shaped surfaces.

- Reduced paint wastage and VOC emissions.

- Long-lasting finishes that minimize maintenance needs.

This technology is vital in marine manufacturing and repair to ensure vessel safety and longevity.

Manufacturing and Industrial Equipment

In general manufacturing, electrostatic spray guns are used to coat machinery, metal structures, tanks, and appliances. Key benefits include:

- Consistent protective coatings that prevent rust and extend equipment life.

- Reduced paint and material costs due to high transfer efficiency.

- Enhanced surface quality and durability.

- Automation compatibility for mass production efficiency.

This helps industrial facilities maintain equipment reliability and appearance with minimal waste.

Medical Equipment Industry

Coatings on medical devices such as MRI machines, surgical tools, and diagnostic equipment must be hygienic and durable. Electrostatic spraying ensures:

- Precise application of coatings for sterilization and corrosion resistance.

- Uniform surfaces to reduce contamination risk.

- Long-lasting finishes that withstand frequent cleaning.

- Compliance with strict health and safety standards.

This industry demands quality finishes that protect both patients and devices.

Electronics and Electrical Equipment

Components like transformers, switchgear, and electronic housings require insulated and protective coatings. Electrostatic spray guns provide:

- Uniform dielectric coatings that improve safety and performance.

- Efficient application on complex electronic components.

- Reduced environmental impact through less overspray.

- Better quality control for sensitive devices.

This enhances reliability and lifespan of electrical equipment.

Construction and Infrastructure

Electrostatic spray coatings are applied to structural steel, bridges, towers, and building components to:

- Protect against corrosion, weather, and environmental damage.

- Ensure long-term durability of infrastructure.

- Minimize paint use and VOC emissions in large-scale projects.

- Provide fast, uniform coverage on large surfaces.

These coatings help reduce maintenance costs and extend the life of critical infrastructure.

Consumer Appliances and Retail Fixtures

Household appliances like refrigerators, ovens, and retail displays benefit from electrostatic coatings that provide:

- Attractive, uniform finishes resilient to wear and fingerprints.

- Increased production speed with automated spraying.

- Lower paint costs due to efficient material usage.

- Environmentally sustainable manufacturing processes.

This results in better product appearance and durability.

Sporting Goods and Bicycles

Sports equipment and bicycle frames require robust coatings to withstand impact, abrasion, and outdoor exposure. Electrostatic spray guns deliver:

- Durable, consistent finishes that maintain appearance.

- Efficient coverage even on tubular and complex shapes.

- Reduced paint consumption and waste.

- Enhanced product longevity.

This supports performance equipment manufacturers aiming for quality and sustainability.

Advantages of Automatic Electrostatic Spray Guns Across Industries

- High Transfer Efficiency: Up to 90% paint utilization reduces costs significantly.

- Reduced Overspray: Less paint lost in the air decreases environmental pollution.

- Uniform Coating: Even coverage on complex shapes improves product quality.

- Faster Production: Automation integration speeds up manufacturing.

- Lower VOC Emissions: Safer workplace and compliance with environmental regulations.

Future Trends and Market Outlook

The market for automatic electrostatic spray guns is growing steadily due to increasing demand for efficient, eco-friendly coating solutions across industries. Key trends include:

- Integration with IoT for process monitoring and control.

- Development of nozzles for finer atomization and greater surface coverage.

- Rising use in electric vehicle manufacturing.

- Expansion in emerging economies with industrial growth.

- Continuous innovation to reduce VOC emissions and enhance ergonomics.

Common Questions and Answers

1. What makes electrostatic spray guns more efficient than conventional spray guns?

Electrostatic spray guns charge the paint particles so they are attracted to the grounded surface, ensuring most paint adheres to the target. This reduces overspray and paint waste compared to conventional guns that spray paint in a direct stream without electrical charge.

2. Can electrostatic spray guns be used on non-metal surfaces?

Yes, while electrostatic spray coating is most effective on conductive surfaces like metal, advances have enabled its use on certain non-metal surfaces by using conductive primers or specialized formulations that build an electrostatic field.

3. Are electrostatic spray guns environmentally friendly?

Yes, these spray guns reduce paint waste and VOC emissions, contributing to lower environmental pollution. This aligns with global regulations aiming to reduce the ecological impact of industrial coatings.

4. What types of coatings can be applied using automatic electrostatic spray guns?

A wide variety of coatings can be applied, including paints, powders, primers, lacquers, and protective finishes tailored to the specific needs of automotive, aerospace, marine, and other industries.

5. How does automation enhance the use of electrostatic spray guns?

Automation ensures precise, repeatable coating application with minimal human error. It increases throughput, reduces labor costs, and improves safety in industrial painting processes.

[1] https://www.codinter.com/en/electrostatic-vs-conventional-painting-which-process-is-better/

[2] https://www.linkedin.com/pulse/global-electrostatic-spray-guns-market-future-j9sdf/

[3] https://ai.otson.com/electrostatic-painting-the-process-and-benefits/

[4] https://patents.google.com/patent/WO2022027736A1/en

[5] https://elmbridgeuk.com/learning-hub/7-reasons-to-use-an-electrostatic-spray-gun/

[6] https://patents.google.com/patent/CN1006447B/zh

[7] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/how-electrostatic-guns-can-benefit-your-facility.html

[8] https://pubchem.ncbi.nlm.nih.gov/patent/CN-213669935-U

[9] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/advantages-of-spraying-with-electrostatic-guns.html

[10] https://patents.google.com/patent/CN101184555B/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.