Content Menu

● What Is an Automatic Electrostatic Spray Gun System?

>> Understanding Electrostatic Spraying Technology

>> The Addition of Automation

● Key Benefits of Upgrading to an Automatic Electrostatic Spray Gun System

>> Improved Production Speed and Capacity

>> Enhanced Coating Efficiency and Reduced Waste

>> Consistently Superior Coating Quality

>> Versatility to Handle Diverse Coatings and Complex Shapes

>> Environmental and Safety Advantages

>> Ease of Use and Maintenance

● How Does an Automatic Electrostatic Spray Gun System Work?

>> Electrostatic Charging and Spray Atomization

>> Robotic or Automated Movement Control

>> Digital Control and Monitoring

● Industrial Applications Benefiting from the Upgrade

>> Automotive and Aerospace Industries

>> Industrial Equipment and Machinery

>> Marine Industry

● Economic Impact of Upgrading

>> Return on Investment (ROI)

>> Long-Term Cost Savings

● Common Questions About Automatic Electrostatic Spray Gun Systems

>> 1. What types of coatings can be used with automatic electrostatic spray guns?

>> 2. How much paint savings can I expect compared to manual spraying?

>> 3. Are these systems difficult to operate?

>> 4. Can automatic electrostatic spray guns paint complex shapes effectively?

>> 5. What maintenance is required for these systems?

Electrostatic spray technology has revolutionized the way coatings and paints are applied across many industries. Upgrading from manual or conventional spray guns to an automatic electrostatic spray gun system offers numerous benefits that enhance productivity, quality, and environmental sustainability. This article explores the comprehensive advantages of adopting automatic electrostatic spray gun systems, explaining how these advancements positively impact production efficiency, coating quality, cost savings, and operator safety.

What Is an Automatic Electrostatic Spray Gun System?

Understanding Electrostatic Spraying Technology

Electrostatic spraying uses a device that charges paint or coating particles as they leave the spray gun. These positively charged particles are attracted to the grounded or negatively charged surface of the object being coated. This charge difference creates a magnetic effect that pulls the particles toward the surface, resulting in more uniform coverage and better adhesion compared to traditional spray methods that lack electrical charge.

The Addition of Automation

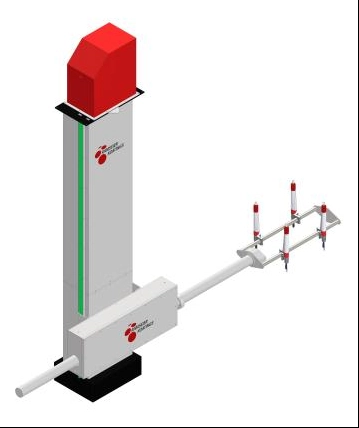

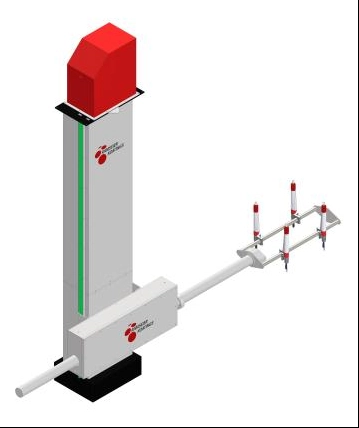

An automatic electrostatic spray gun system integrates this electrostatic technology with robotic or automated control mechanisms. The system often includes sensors, programmable logic controllers, and automated robotic arms or linear applicators that precisely control the spray gun's movements, spray patterns, and fluid flow rates. This eliminates operator variability and allows consistent, repeatable performance over long production runs.

Key Benefits of Upgrading to an Automatic Electrostatic Spray Gun System

Improved Production Speed and Capacity

One of the most significant advantages of automatic electrostatic spray gun systems is the dramatic increase in production speed. Automated systems move swiftly and accurately over parts, applying coatings much faster than manual spraying. Because robotic systems can operate continuously without fatigue or breaks, they maximize throughput in manufacturing lines, boosting overall production capacity.

Enhanced Coating Efficiency and Reduced Waste

Electrostatic attraction ensures that more coating particles reach and adhere to the target surface and that less paint is lost as overspray. Automatic systems optimize spray paths, flow rates, and spray angles to minimize waste further. This efficient use of coating materials leads to substantial cost savings on expensive paints and reduces the volume of hazardous volatile organic compounds (VOCs) released into the environment.

Consistently Superior Coating Quality

Automation removes human inconsistency from the spraying process. Programmable settings ensure tight control over critical parameters like spray pressure, coating thickness, and deposition patterns. The result is uniform, high-quality finishes with fewer defects such as runs, sags, or dry spots. This reliability is particularly important for long production runs or applications demanding precise coating thickness and excellent aesthetics.

Versatility to Handle Diverse Coatings and Complex Shapes

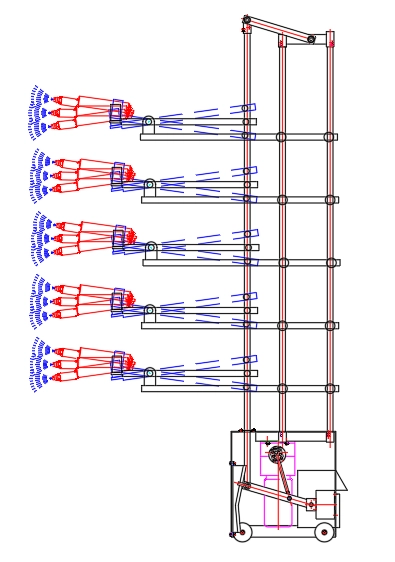

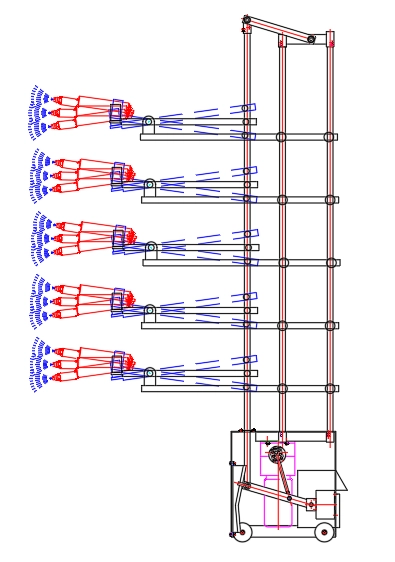

Automatic electrostatic spray systems can be programmed to accommodate various types of coatings, including two-component (2K) systems and water-based paints. Additionally, the electrostatic charge helps coatings wrap around complex geometries, such as tubular or irregular-shaped objects, providing uniform coverage on all surfaces, including hard-to-reach areas. This versatility is vital in industries like automotive, industrial equipment, aerospace, and marine applications.

Environmental and Safety Advantages

By reducing overspray and improving transfer efficiency, these systems generate less airborne paint and fewer VOC emissions, which helps meet increasingly stringent environmental regulations. Automatic systems also reduce operator exposure to potentially hazardous chemicals by minimizing manual handling of spray guns, enhancing workplace safety. Furthermore, many systems are built with safety certifications for operation in potentially explosive atmospheres.

Ease of Use and Maintenance

Modern automatic electrostatic spray systems come with user-friendly control panels that allow operators to customize and store multiple coating parameters for different parts or batches. This flexibility facilitates quick changeovers and consistent results. The systems are typically designed for straightforward maintenance with features that minimize downtime and keep operations running smoothly.

How Does an Automatic Electrostatic Spray Gun System Work?

Electrostatic Charging and Spray Atomization

The spray gun charges liquid coating particles electrostatically as they pass through or near a charged electrode inside the nozzle. This charging process is often combined with advanced atomization techniques, such as rotary atomizers or induction electrostatic spray heads, to create finely dispersed droplets that enhance surface coverage.

Robotic or Automated Movement Control

Robotic arms, linear tracks, or rotary indexers automate the physical movement of the spray gun. Sensors and vision systems may be included to scan part geometries and adjust spraying parameters dynamically. These systems ensure every part is coated evenly while optimizing the spray path for minimal waste.

Digital Control and Monitoring

Integrated control panels enable real-time adjustment of spray parameters such as voltage, flow rate, rotation speed of atomizers, and gun movement speed. Some systems record and store multiple settings for easy recall, ensuring process stability across different product types or production runs.

Industrial Applications Benefiting from the Upgrade

Automotive and Aerospace Industries

The automotive sector widely uses automated electrostatic spray guns for applying primers, base coats, and clear coats in car manufacturing. The precision and efficiency of these systems improve finish quality and reduce paint consumption. Aerospace component manufacturers also benefit by achieving flawless coatings critical for performance and protection.

Industrial Equipment and Machinery

Heavy equipment and industrial machinery often involve large surface areas and complex shapes. Automated electrostatic spray systems speed coating applications while providing corrosion resistance and durable finishes crucial for harsh operating environments.

Marine Industry

Coatings applied in marine environments must resist saltwater corrosion and mechanical wear. Automatic electrostatic systems ensure consistent, thick layers of protective paints on hulls and equipment, enhancing longevity and reducing maintenance costs.

Economic Impact of Upgrading

Return on Investment (ROI)

Although the initial cost of installing an automatic electrostatic spray system can be substantial, businesses often see a quick ROI through:

- Significant reductions in paint usage due to higher transfer efficiency.

- Lower labor costs because fewer operators are needed and production speeds increase.

- Reduced waste disposal and environmental compliance costs.

- Decreased rework and quality assurance expenses due to improved finish quality.

Long-Term Cost Savings

The durable design, easier maintenance, and higher reliability of automatic systems reduce downtime and replacement costs. Simultaneously, energy-efficient components and lower VOC emissions can save money and bolster corporate sustainability initiatives.

Common Questions About Automatic Electrostatic Spray Gun Systems

1. What types of coatings can be used with automatic electrostatic spray guns?

They can handle a wide range of coatings, including solvent-based paints, water-based paints, 2K systems, and powder coatings, depending on the specific system design.

2. How much paint savings can I expect compared to manual spraying?

Typically, automatic electrostatic systems can reduce paint usage by 30% to 50% or more through optimized transfer efficiency and reduced overspray.

3. Are these systems difficult to operate?

Modern automatic electrostatic spray systems are designed with intuitive control panels and programmable settings, making them easy to operate with proper training.

4. Can automatic electrostatic spray guns paint complex shapes effectively?

Yes, the electrostatic charge helps wrap paint around irregular shapes, enhancing coverage on complex geometries, which is difficult for conventional spray guns.

5. What maintenance is required for these systems?

Maintenance typically includes cleaning nozzles, checking electrode conditions, and periodic calibration of spray parameters. Many systems have built-in cleaning and diagnostic routines to simplify upkeep.

[1] https://ai.otson.com/coating-electrostatic-spray/ots-8000-auto-electrostatic-spray-gun-system/

[2] https://www.linkedin.com/pulse/future-spray-guns-electrostatic-spraying-technology-ruehf

[3] https://www.codinter.com/en/automatic-spray-guns-a-complete-guide/

[4] https://patents.google.com/patent/CN1006447B/zh

[5] https://elmbridgeuk.com/learning-hub/7-reasons-to-use-an-electrostatic-spray-gun/

[6] https://pubchem.ncbi.nlm.nih.gov/patent/CN-213669935-U

[7] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/advantages-of-spraying-with-electrostatic-guns.html

[8] https://patents.google.com/patent/WO2021012778A1/zh

[9] https://www.graco.com/gb/en/in-plant-manufacturing/solutions/articles/advantages-of-spraying-with-electrostatic-guns.html

[10] https://patents.google.com/patent/CN101351273B/en

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.