Content Menu

● Introduction

● Overview of Manual Spray Booths

>> Energy Efficiency in Manual Booths

● Overview of Automated Spray Booths

>> Energy Efficiency in Automated Booths

● Key Technologies for Energy Efficiency

>> LED Lighting

>> Variable Frequency Drives (VFDs)

>> Heat Recovery Systems

>> Direct-Fired Modulating Burners

>> Automated Controls

● Challenges and Considerations

>> Initial Investment

>> Maintenance and Upgrades

>> Training and Workforce Adaptation

● Conclusion

>> Frequently Asked Questions

● Citations:

Introduction

In the automotive and industrial sectors, spray booths play a crucial role in ensuring high-quality finishes for products. However, these booths are energy-intensive, primarily due to their ventilation, temperature control, and lighting requirements. As businesses strive to reduce operational costs and environmental impact, the debate between manual and automated spray booths has gained significant attention. This article explores the energy efficiency of both types, highlighting their features, benefits, and challenges.

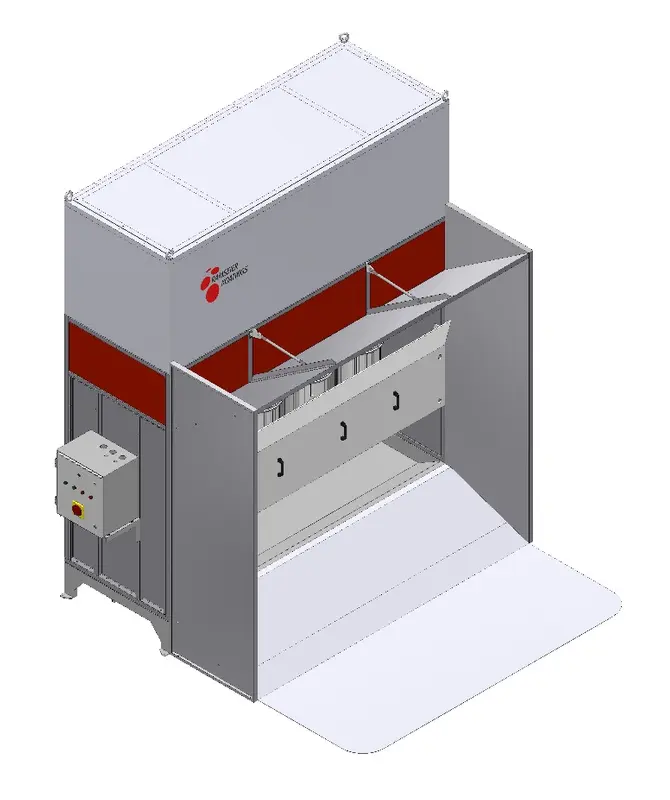

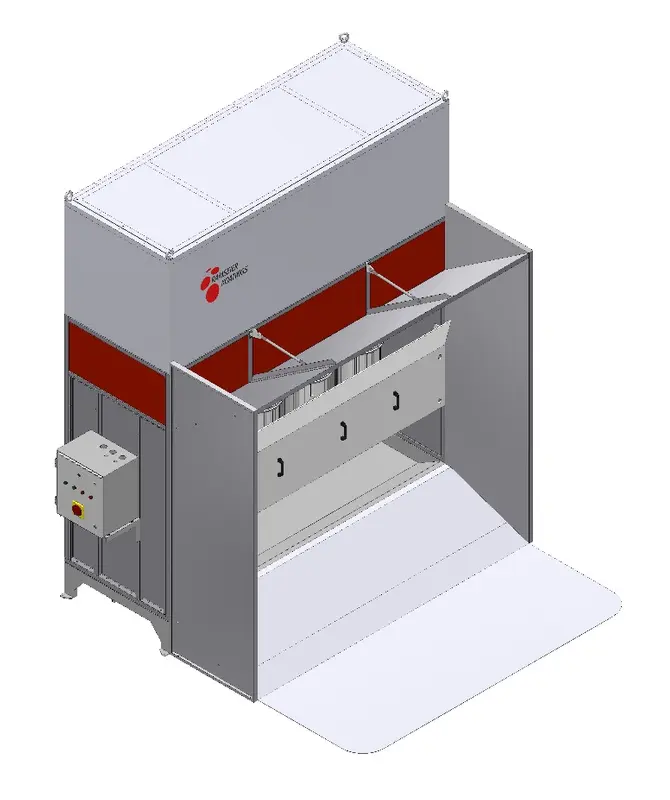

Overview of Manual Spray Booths

Manual spray booths are favored for their precision and control, making them ideal for custom jobs and small batches. These booths require skilled labor, which can increase labor costs and time per unit. Despite their adaptability, manual booths often lead to inconsistencies in application, affecting finish quality. Energy efficiency in manual booths largely depends on operator practices and equipment maintenance.

Energy Efficiency in Manual Booths

Improving energy efficiency in manual booths involves upgrading to energy-efficient lighting, such as LED lights, and optimizing airflow through regular maintenance. Ensuring that all components operate efficiently is crucial, as clogged filters or inefficient motors can significantly increase energy consumption. Additionally, implementing variable frequency drives (VFDs) on motor-driven equipment can reduce energy usage by allowing motors to operate at lower speeds when full power is not needed.

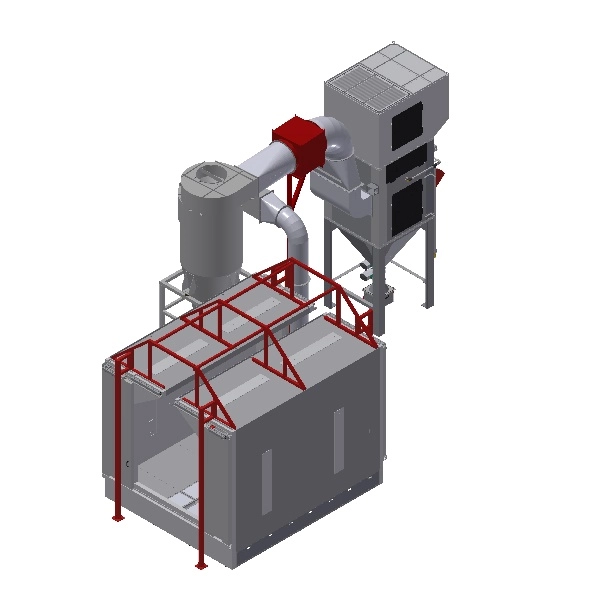

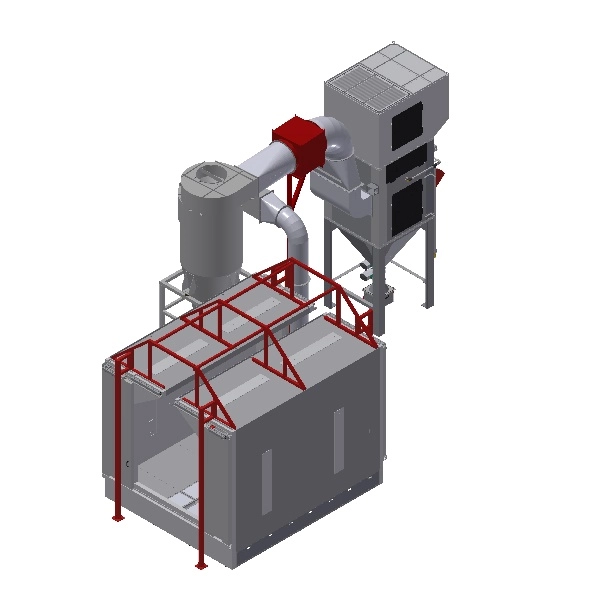

Overview of Automated Spray Booths

Automated spray booths excel in high-volume production settings, offering unparalleled consistency and efficiency. These systems ensure uniform application, reduce waste, and improve throughput. While the initial investment is higher, the return on investment is significant due to reduced labor costs and increased production speed. Automated booths are equipped with advanced features like precision nozzles and controlled environments, ensuring optimal spraying conditions.

Energy Efficiency in Automated Booths

Automated spray booths are generally more energy-efficient than manual ones due to their ability to optimize energy consumption through advanced technologies. Features such as smart control panels, heat recovery systems, and VFDs allow automated booths to adjust energy usage based on real-time needs. For instance, economy or standby modes can drop processes to idle when not in use, saving significant amounts of electrical and fuel energy. Additionally, automated systems can integrate AI and machine learning to predict maintenance needs and adjust settings for optimal performance.

Key Technologies for Energy Efficiency

Several technologies are crucial for enhancing energy efficiency in spray booths, whether manual or automated:

LED Lighting

Switching to LED lighting is one of the most straightforward upgrades for spray booths. LEDs use significantly less energy than traditional lighting solutions and produce less heat, which can indirectly reduce cooling costs. This transition not only saves energy directly but also enhances the working environment, leading to better productivity and outcomes.

Variable Frequency Drives (VFDs)

VFDs control the speed of motors in spray booths, allowing them to operate at lower speeds when full power is not needed. This reduces energy consumption and extends the lifespan of the motors. Implementing VFDs on exhaust fans and other motor-driven equipment is a cost-effective way to enhance energy efficiency without compromising safety or performance.

Heat Recovery Systems

Heat recovery systems capture waste heat generated during the painting process and reuse it to preheat incoming air. This significantly reduces the amount of energy required to heat the spray booth, offering long-term savings and environmental benefits.

Direct-Fired Modulating Burners

These burners provide precise temperature control while minimizing energy consumption and emissions. By directly heating the air, they improve heat transfer efficiency compared to traditional heat exchangers.

Automated Controls

Automated controls optimize the operation of spray booths by adjusting airflow, temperature, and lighting based on real-time needs. This ensures that the booth operates at peak efficiency without wasting energy. Advanced control systems can also provide real-time monitoring and adjustments, allowing for consistent operating conditions and reduced manual intervention.

Challenges and Considerations

Initial Investment

Automated spray booths require a higher initial investment compared to manual booths. This includes the cost of equipment, installation, and training. However, the long-term benefits of increased efficiency and reduced operational costs often outweigh these expenses.

Maintenance and Upgrades

Automated systems require regular maintenance to ensure optimal performance. Keeping up with technological advancements and upgrades is crucial for staying competitive in the industry.

Training and Workforce Adaptation

Introducing automated systems requires training for the workforce to manage and maintain the equipment properly. This transition can be challenging for companies with limited experience in automation.

Conclusion

In conclusion, while both manual and automated spray booths have their advantages, automated booths generally offer superior energy efficiency due to their ability to integrate advanced technologies that optimize energy consumption. As industries continue to prioritize sustainability and cost management, investing in energy-efficient technologies will become increasingly essential for competitive and responsible business practices.

---

Frequently Asked Questions

1. What are the primary energy consumers in a spray booth?

- The biggest energy users in a spray booth are process uses, lighting, VOC control, and HVAC systems.

2. How do variable frequency drives (VFDs) improve energy efficiency?

- VFDs control motor speed, allowing them to operate at lower speeds when full power is not needed, reducing energy consumption and extending motor lifespan.

3. What are the benefits of using LED lighting in spray booths?

- LED lighting reduces energy consumption, produces less heat, and offers better color accuracy, enhancing the working environment and productivity.

4. How do heat recovery systems contribute to energy efficiency?

- Heat recovery systems capture waste heat and reuse it to preheat incoming air, significantly reducing heating costs and environmental impact.

5. What role does automation play in improving energy efficiency?

- Automation optimizes energy consumption by adjusting airflow, temperature, and lighting based on real-time needs, ensuring peak efficiency without wasting energy.

---

Citations:

[1] https://pfsspraybooths.com/how-to-improve-energy-efficiency-in-your-spray-booth

[2] https://www.sdge.com/automotive-body-repair-paint-shop-energy-usage

[3] https://www.accudraftpaintbooths.com/accudrafts-news/new-or-used-paint-booth-energy-efficiency/

[4] https://www.betagroupltd.com/equipment/energy-saving-technologies/

[5] https://airblast.co.uk/resource-hub/blog/spray-booth-efficiency/

[6] https://www.cxhuarui.com/Maximizing-Efficiency-with-Automatic-Spray-Booths-id40271556.html

[7] https://www.pcimag.com/articles/94052-improving-booth-energy-efficiency

[8] https://www.pbmetalfinishingsystems.com/news/comparing-manual-vs-automated-spray-equipment-for-industrial-applications

[9] https://www.paintbooth.com/how-energy-efficient-are-modern-paint-booths/

[10] https://www.fenderbender.com/home/article/33035666/latest-paint-booths-expand-capabilities-improve-efficiency

[11] https://www.ramseierkoatings.com/automatic-vs-manual-spray-booths-which-offers-better-environmental-protection.html

[12] https://www.junair-spraybooths.co.uk/advantages-of-going-green-with-your-spray-booth/

[13] https://globalfinishing.com/2013/04/22/earth-day-energy-saving-5-pieces-of-paint-booth-tech-that-do-more-and-use-less/

[14] https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P100OZF5.txt

[15] https://globalfinishing.com/2019/09/20/how-to-save-energy-in-your-paint-booth-with-a-vfd/

[16] https://www.codinter.com/en/spray-booths-a-complete-guide/

[17] https://www.linkedin.com/pulse/exploring-heating-methods-spray-paint-booths-efficiency-gnadc

[18] https://www.junair-spraybooths.co.uk/how-to-make-your-spray-booth-more-energy-efficient/

[19] https://www.spraysystems.com/nfpa-33/

[20] https://www.ramseierkoatings.com/news/Energy-Efficiency-in-Automatic-Spray-Booths-Compared-to-Manual-Systems.html

[21] https://www.nordson.com/en/products/industrial-coating-systems-products/manual-powder-coating-booth

[22] https://www.fujielectric.fr/en/applications/paint-booths-how-reduce-energy-consumption-while-maintaning-optimum-quality/

[23] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[24] https://pfsspraybooths.com/how-to-improve-energy-efficiency-in-your-paint-booth

[25] https://www.usiitalia.com/en/category_prodotti/booths/high-efficiency-spray-booth/

[26] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/why-you-should-automate-your-paint-booth.html

[27] https://www.ramseierkoatings.com/what-are-the-advantages-of-automatic-spray-booth-systems-over-semi-automatic-ones.html

[28] https://reliantfinishingsystems.com/deciding-if-an-automated-coating-system-is-right-for-your-operation/

[29] https://www.ramseierkoatings.com/manual-spray-booths-vs-automated-systems-which-is-easier-to-maintain.html

[30] https://puretemac.com/Selection-Guide-for-Automatic-Spray-Painting-Machine-Systems.html

[31] https://gsbindustries.com/the-evolution-of-paint-booth-technology/

[32] https://archive.epa.gov/epa/sites/production/files/2015-06/documents/isocyanate_profile_chapter_5.pdf

[33] https://www.sdge.com/sites/default/files/energy-saving-cards/29_Automotive%20Body%20Repair%20Paint%20Shop%20Tips.pdf

[34] https://www.accudraftpaintbooths.com/accudraft-tips/how-can-i-save-energy-using-my-paint-booth/

[35] https://exhibitorsearch.messefrankfurt.com/images/original/document_downloads/10000007202401/309194/1714652573432_4049762436.pdf

[36] https://www.ceflafinishing.com/en/products/manual-spray-booths-for-finishing

[37] https://airknowledge.gov/ILT/TOXC220/Current/CI/04TOXC220_Handout_Innovative_Spray_Booth_Technology.pdf

[38] https://vocal.media/journal/the-future-is-here-the-exciting-developments-in-spray-booth-technology

[39] http://www.rammsteinair.com/index.php?id=164

[40] https://www.usius.com/spray-booth-gas-or-electric/

[41] https://www.spraysystems.com/energy-efficiency-that-doesnt-hinder-your-options/

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.