Content Menu

● Introduction

● Understanding Transfer Efficiency and Its Importance

>> What Is Transfer Efficiency?

>> Why Transfer Efficiency Matters

● How Electrostatic Spray Guns Work

>> Basics of Electrostatic Spraying

>> Automatic vs. Manual Electrostatic Guns

● Key Factors to Maximize Transfer Efficiency

>> Gun Voltage Settings

>> Gun-to-Part Distance

>> Powder or Paint Particle Velocity

>> Part Grounding and Orientation

● Proper Equipment Setup

>> Selecting the Right Spray Gun and Nozzle

>> Air Pressure and Fluid Pressure Settings

>> Gun Motion and Speed

● Environmental and Operational Considerations

>> Spray Booth Airflow and Balance

>> Operator Training and Monitoring

>> Maintenance and Calibration

● Advanced Techniques for Transfer Efficiency Improvement

>> Multi-Gun Coordination in Automated Lines

>> Use of Pattern Adjustment Knobs

>> Supplemental Grounding Methods

● Common Challenges and Solutions

>> Electrostatic Rejection and Faraday Cage Effects

>> Managing Environmental Conditions

>> Overcoming Operator Fatigue in Semi-Automatic Lines

● FAQ Section

>> 1. What is the ideal distance between an electrostatic spray gun and the part?

>> 2. How does part grounding affect transfer efficiency?

>> 3. Can automatic electrostatic spray guns be used on complex-shaped parts?

>> 4. How often should spray guns be cleaned and calibrated?

>> 5. What operator practices help maximize transfer efficiency?

● Conclusion

Introduction

Automatic electrostatic spray guns are widely used in industrial painting and coating processes due to their ability to improve transfer efficiency—the percentage of coating material that actually adheres to the target surface. Maximizing transfer efficiency not only reduces material waste but also lowers costs and environmental impact. This article explores practical techniques, equipment settings, and operational strategies to achieve peak transfer efficiency with automatic electrostatic spray guns.

Understanding Transfer Efficiency and Its Importance

What Is Transfer Efficiency?

Transfer efficiency (TE) measures how much coating material reaches and sticks to the part compared to how much material is sprayed and wasted as overspray. For example, a 60% TE means 60% of the sprayed paint coats the part, while 40% is lost.

Why Transfer Efficiency Matters

Improving TE can lead to significant savings in paint or powder costs, reduce hazardous emissions, and improve coating quality and consistency. Efficient coating also reduces cleanup and environmental compliance costs.

How Electrostatic Spray Guns Work

Basics of Electrostatic Spraying

Electrostatic spray guns charge coating particles electrically, typically via corona charging or triboelectric charging. The charged particles are attracted to the grounded part surface due to opposite electrical charges, enabling better material adherence and reduced overspray.

Automatic vs. Manual Electrostatic Guns

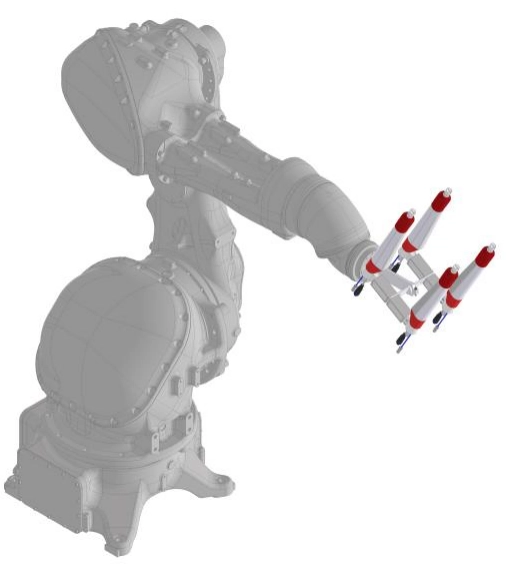

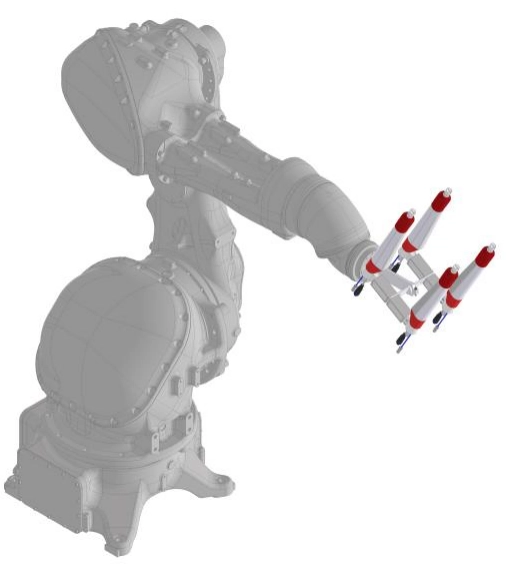

Automatic guns are integrated into production lines, offering consistent spray patterns and motion control. They enable precise application, repeatability, and often higher transfer efficiency compared to manual spraying.

Key Factors to Maximize Transfer Efficiency

Gun Voltage Settings

Start with the highest voltage your gun can safely handle to maximize the charge on coating particles, which improves attraction to the part surface. Adjust voltage to balance against issues like electrostatic rejection (“starring”) or Faraday cage effects in recessed areas.

Gun-to-Part Distance

Maintain an optimal distance of about 6 to 12 inches between the spray gun and the part surface. Closer distances may disrupt electrostatic fields and cause inefficiencies, while too far distances reduce particle charge effectiveness.

Powder or Paint Particle Velocity

Slower particle velocity increases the time particles spend in the electrostatic field, enhancing transfer efficiency. Reducing powder flow velocity and slowing gun motion helps particles better adhere to surfaces.

Part Grounding and Orientation

Ensure the part is properly grounded with resistance less than or equal to 1 megohm to facilitate the electrostatic attraction. Orient parts so the primary surfaces face the spray guns to minimize coating waste and maximize efficiency.

Proper Equipment Setup

Selecting the Right Spray Gun and Nozzle

Choose electrostatic spray guns designed for automatic application with appropriate nozzle sizes for part geometry. Larger nozzles for bigger surfaces and smaller nozzles for intricate parts optimize distribution and reduce bounce-back.

Air Pressure and Fluid Pressure Settings

Use balanced air and fluid pressure to minimize overspray and maximize coating transfer. Too much air pressure disrupts the coating pattern and causes waste, while too little reduces atomization quality.

Gun Motion and Speed

Program consistent and slow gun movement for automatic guns to allow sufficient particle charge time and effective coverage. Avoid rapid motions that reduce transfer efficiency.

Environmental and Operational Considerations

Spray Booth Airflow and Balance

Maintain proper airflow and ventilation to reduce paint or powder blow-off and recapture overspray. Balanced airflow helps direct coating particles toward the target surface.

Operator Training and Monitoring

Ensure operators understand optimal setup, gun distance, triggering techniques, and part positioning. Regular training and monitoring improve consistency and identify areas for improvement.

Maintenance and Calibration

Regularly clean and calibrate spray guns and equipment to maintain charging efficacy and spray pattern quality. Equipment wear or dirt buildup can reduce transfer efficiency.

Advanced Techniques for Transfer Efficiency Improvement

Multi-Gun Coordination in Automated Lines

Coordinate multiple automatic guns in complex part stations to minimize overlap and overspray. Optimize trigger timing and movement paths to cover surfaces evenly.

Use of Pattern Adjustment Knobs

Utilize fan pattern adjustments on guns to tailor spray width to specific part sizes and shapes, reducing wasted coating outside the target zone.

Supplemental Grounding Methods

In addition to part grounding, grounding the surrounding environment or conveyor system can improve charge attraction and reduce errant spray.

Common Challenges and Solutions

Electrostatic Rejection and Faraday Cage Effects

Recession areas or sharp edges may repel charged particles, resulting in uneven coating. Solutions include adjusting voltage, part orientation, or using additional guns for hard-to-coat zones.

Managing Environmental Conditions

High humidity or dust can reduce electrostatic efficiency. Control temperature, humidity, and cleanliness in spraying areas to optimize performance.

Overcoming Operator Fatigue in Semi-Automatic Lines

Automated spray arms and robotics can sustain consistent application and efficiency, reducing operator-induced variability.

FAQ Section

1. What is the ideal distance between an electrostatic spray gun and the part?

The ideal distance is generally between 6 to 12 inches. Maintaining this range ensures the electrostatic field effectively attracts charged particles without disrupting the spray pattern.

2. How does part grounding affect transfer efficiency?

Proper grounding (resistance ≤ 1 megohm) is critical because it completes the electrostatic circuit, attracting charged particles to the part and maximizing coating adherence.

3. Can automatic electrostatic spray guns be used on complex-shaped parts?

Yes, but it requires careful part orientation, multi-gun setups, and sometimes adjustments in spray parameters to overcome Faraday cage effects in recessed areas.

4. How often should spray guns be cleaned and calibrated?

Cleaning and calibration should be done regularly, ideally daily or weekly depending on use, to maintain charging efficiency and consistent spray patterns.

5. What operator practices help maximize transfer efficiency?

Proper training on spray distance, gun speed, triggering timing, part positioning, and understanding equipment settings greatly enhance transfer efficiency.

Conclusion

Maximizing transfer efficiency using automatic electrostatic spray guns requires a combination of proper equipment choice, precise settings, well-maintained machinery, and skilled operation. By optimizing voltage, distance, particle velocity, grounding, and part orientation, manufacturers can achieve better coating results, reduce waste, and lower overall costs.

[1](https://www.powdercoatedtough.com/News/ID/48/5-Steps-to-Improve-Transfer-Efficiency)

[2](https://www.powdercoatingonline.com/transfer-efficiency/)

[3](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/tips-for-improving-transfer-efficiency.html)

[4](https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/reduce-your-coating-costs-by-maximizing-transfer-efficiency)

[5](https://www.chreed.com/how-to-increase-transfer-efficiency/)

[6](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/electrostatic-spray-gun-basics.html)

[7](https://www.bolair.ca/blog/improving-transfer-efficiency-paint-spray-guns/)

[8](https://www.airpower-usa.com/2020/04/03/improving-your-electrostatic-process/)

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.