Content Menu

● Understanding Spray Gun Units

>> What is a Spray Gun Unit?

>> Components of a Spray Gun Unit

● Spray Gun Units for Small-Scale Production Lines

>> Characteristics of Spray Guns for Small Production

>> Common Types Used in Small Lines

>> Advantages for Small-Scale Production

>> Limitations

● Spray Gun Units for Large-Scale Production Lines

>> Characteristics of Spray Guns for Large Production

>> Common Types Used in Large Lines

>> Advantages for Large-Scale Production

>> Limitations

● Comparing Small vs Large-Scale Spray Gun Units

● Selecting the Right Spray Gun Unit

>> Production Requirements

>> Budget Considerations

>> Technical Expertise

>> Product Complexity

● Maintenance and Operational Best Practices

>> Maintenance Tips for Small Units

>> Maintenance Tips for Large Units

>> Safety Considerations

● Future Trends in Spray Gun Technology

● FAQ

In the manufacturing and finishing industries, spray gun units play a critical role in applying coatings, paints, and finishes efficiently and uniformly. Choosing the right spray gun unit is essential, whether for small-scale workshops or large production lines, because it directly impacts product quality, production speed, and operational costs. This article explores the differences between spray gun units designed for small and large-scale production lines, focusing on their features, benefits, limitations, and suitable applications.

Understanding Spray Gun Units

Before diving into comparisons, it is important to understand what spray gun units are and their general functions.

What is a Spray Gun Unit?

A spray gun unit is a device used to atomize liquid material such as paint or coatings into a fine spray, allowing for smooth, even application onto surfaces. These units can be manual, automated, or semi-automated and vary in size, design, and power depending on the intended use.

Components of a Spray Gun Unit

Key components of a spray gun unit typically include the nozzle, air cap, fluid needle, trigger mechanism, and sometimes an air compressor or pump system. Variations in these parts influence the spray pattern, flow rate, and finish quality.

Spray Gun Units for Small-Scale Production Lines

Small-scale production lines typically cater to lower volume manufacturing, custom jobs, artisanal products, or prototypes. Spray gun units designed for these environments emphasize flexibility, ease of use, and cost-efficiency.

Characteristics of Spray Guns for Small Production

- Portability: These units are often handheld or compact, facilitating mobility and ease of operation.

- Versatility: Capable of handling multiple coatings including lacquers, enamels, and water-based paints.

- User-Friendly Controls: Simple adjustment settings for spray patterns and flow rates suited for operators who may not be specialists.

- Lower Throughput: Designed for small batch runs with lower paint volume requirements.

Common Types Used in Small Lines

- HVLP (High Volume Low Pressure) Spray Guns: Popular for their efficiency and clean finish, especially suitable for detailed work.

- Airbrushes: Used for extremely fine, detailed coating in prototypes or craft items.

- Gravity Feed Guns: Ideal for small projects with quick changeover between paint types.

Advantages for Small-Scale Production

- Cost-Effective: Lower initial investment and operating costs.

- Precision: Ability to handle intricate designs and finishes.

- Reduced Overspray: Saves material due to better transfer efficiency.

- Ease of Maintenance: Smaller parts and less complicated systems simplify upkeep.

Limitations

- Slower Production Speeds: Not designed for rapid, continuous coating.

- Limited Coverage: Better for smaller surfaces, less efficient for large volumes.

- Operator Dependent: Consistency depends heavily on the skill of the user.

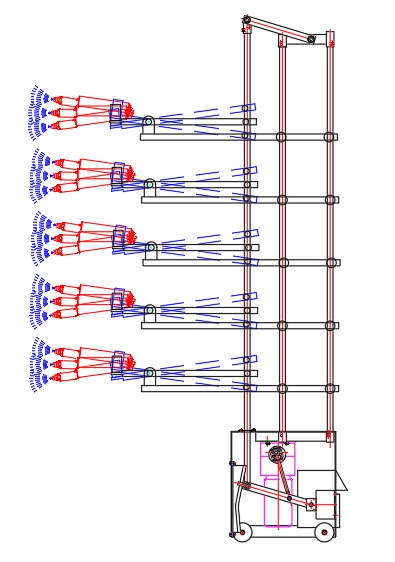

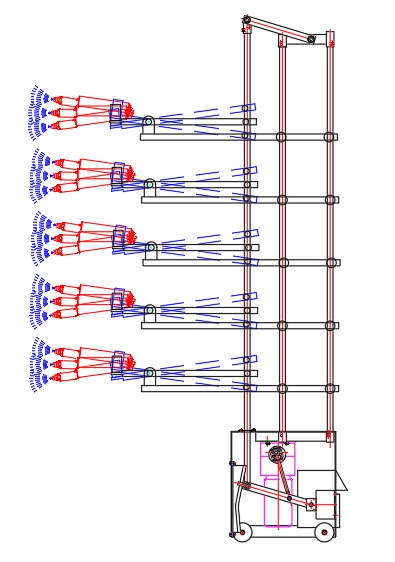

Spray Gun Units for Large-Scale Production Lines

Large-scale production lines are implemented in high-volume manufacturing environments such as automotive, appliance, and industrial equipment factories. The spray gun units here are engineered for speed, consistency, durability, and integration into automated systems.

Characteristics of Spray Guns for Large Production

- High Throughput: Capable of coating large surface areas quickly.

- Automation Compatible: Designed for integration with robotic arms and conveyor systems.

- Durability: Built to withstand long operational hours with minimal downtime.

- Advanced Control Systems: Digital or pneumatic systems manage precise flow and spray parameters automatically.

Common Types Used in Large Lines

- Electrostatic Spray Guns: Use an electric charge to improve paint adhesion and reduce overspray in high-volume applications.

- Airless Spray Guns: Pump paint at high pressure without compressed air, ideal for thick coatings and fast coverage.

- Robotic Spray Systems: Automated units used in assembly lines for consistent and repetitive coating applications.

Advantages for Large-Scale Production

- Efficiency: High speed reduces cycle times and increases output.

- Consistency: Automated and robotic systems ensure uniform coating quality.

- Material Savings: Advanced technology reduces paint waste.

- Reduced Labor Costs: Automation minimizes manual labor and associated costs.

Limitations

- High Initial Investment: Equipment and integration costs are substantial.

- Less Flexibility: Changing colors or coatings can be time-consuming and costly.

- Complex Maintenance: Requires skilled technicians for upkeep and troubleshooting.

Comparing Small vs Large-Scale Spray Gun Units

| Aspect | Small-Scale Units | Large-Scale Units |

| Production Volume | Low to moderate batch sizes | High volume continuous production |

| Cost | Lower purchase and operating cost | Significantly higher investment |

| Automation | Mostly manual or semi-automated | Fully automated or robotic integration |

| Flexibility | High, changes easily with minimal downtime | Lower, changes require downtime and recalibration |

| Finish Quality | High quality but operator-dependent | Extremely consistent with automation |

| Maintenance | Easier, less technical | More complex, requires specialized service |

| Application | Ideal for custom, prototype, or low volume goods | Best for mass production of consistent products |

Selecting the Right Spray Gun Unit

Choosing between small and large-scale spray gun units depends on several factors.

Production Requirements

Evaluate your production volume, frequency, and speed needs. Small units are better for varied, low-volume needs; large units excel in stable, high-volume environments.

Budget Considerations

Installations for large-scale units require significant capital, training, and maintenance budgets. Small units are more economical upfront and flexible for smaller operations.

Technical Expertise

Analyze available manpower skills. Automated large-scale systems demand skilled technicians, whereas small-scale units require trained operators but less technical maintenance.

Product Complexity

For intricate designs, detailed finishes, or frequent product changes, small-scale units offer better adaptability. Large-scale units perform best with consistent, repetitive coating processes.

Maintenance and Operational Best Practices

Proper maintenance of spray gun units ensures sustained performance and quality.

Maintenance Tips for Small Units

- Regular cleaning after each use to prevent clogging.

- Frequent inspection of nozzles and needles.

- Use of proper filters to avoid contaminants.

- Lubrication of mechanical parts as recommended.

Maintenance Tips for Large Units

- Scheduled preventive maintenance adhering to manufacturer guidelines.

- Calibration of automated controls to maintain consistency.

- Replacement of wear parts based on runtime metrics.

- Training operators and technicians on troubleshooting common issues.

Safety Considerations

Regardless of scale, ensure proper ventilation, use of protective equipment, and compliance with environmental laws regarding overspray and VOC emissions.

Future Trends in Spray Gun Technology

Advances in technology are bridging the gap between small and large-scale units, offering more efficient, environmentally friendly, and versatile solutions.

- Smart Spray Guns: Integration with IoT for real-time monitoring and adjustment.

- Low VOC and Waterborne Coatings: Environmentally responsible materials requiring specialized equipment.

- Hybrid Systems: Combining manual control with robotic assistance for flexible production.

- Enhanced Automation: Increased use of AI and machine learning for optimizing line performance.

FAQ

1. What spray gun type is best for small workshops?

HVLP and gravity feed spray guns are preferred for their precision, ease of use, and efficient material use in small-scale settings.

2. Can large-scale spray guns be used for small projects?

While technically possible, large-scale spray guns are inefficient for small jobs due to their size, cost, and operational complexity.

3. How often should spray guns be maintained?

Small units require cleaning after each use, while large units should follow a strict preventive maintenance schedule, often daily or weekly depending on use.

4. What are the main differences between airless and HVLP spray guns?

Airless guns use high pressure without compressed air for thicker coatings and faster coverage, while HVLP guns use lower pressure for finer finishes with less overspray.

5. Are robotic spray systems suitable for all industries?

They are ideal for high-volume, repetitive applications like automotive or appliance manufacturing but may not suit industries requiring high customization or small lots.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.