Content Menu

● Understanding Heat-Sensitive Materials and Their Challenges

>> What Are Heat-Sensitive Materials?

>> Challenges in Spraying Heat-Sensitive Materials

● Essential Features of Spray Guns for Heat-Sensitive Materials

>> Precise Temperature Control

>> Optimal Atomization Technology

>> Non-Metallic Material Contact Surfaces

>> Ease of Cleaning and Maintenance

● Types of Spray Gun Units Suitable for Heat-Sensitive Materials

>> Air-Assisted Airless Spray Guns

>> Electrostatic Spray Guns

>> HVLP (High Volume Low Pressure) Spray Guns

>> Cold Spray Guns

● Comparing Popular Spray Gun Units for Heat-Sensitive Materials

● Key Considerations When Choosing the Optimal Spray Gun Unit

>> Material Compatibility

>> Temperature Monitoring and Control

>> Application Environment

>> Maintenance and Cleaning

>> Cost and Production Volume

● Practical Tips for Spraying Heat-Sensitive Materials

● Identifying the Best Spray Gun Unit: Case Examples

>> Case 1: Medical Device Coatings

>> Case 2: Food-Grade Packaging

>> Case 3: Automotive Clear Coats

● Frequently Asked Questions

>> 1. Why is temperature control critical when spraying heat-sensitive materials?

>> 2. Can any spray gun be used for heat-sensitive materials?

>> 3. How does HVLP differ from air-assisted airless spraying for sensitive coatings?

>> 4. Is electrostatic spraying safe for all heat-sensitive materials?

>> 5. How often should spray guns be cleaned when used with heat-sensitive coatings?

Spray gun technology has advanced significantly, offering a range of options for various industrial applications. When working with heat-sensitive materials, choosing the right spray gun unit is critical to maintain material integrity and achieve optimum results. This article will explore the best spray gun units for handling heat-sensitive materials, taking into account the unique challenges and requirements such coatings present. We will discuss factors such as temperature control, atomization quality, material compatibility, and operational efficiency, providing guidance for professionals seeking the ideal spray gun for these sensitive applications.

Understanding Heat-Sensitive Materials and Their Challenges

What Are Heat-Sensitive Materials?

Heat-sensitive materials are substances that degrade, change properties, or lose their effectiveness when exposed to excessive heat during processing. These include certain polymers, thermoplastics, biomaterials, adhesives, paints, and pharmaceutical coatings. Processing such materials requires stringent temperature control to prevent defects such as discoloration, curing, or chemical breakdown.

Challenges in Spraying Heat-Sensitive Materials

- Thermal degradation: High temperatures can cause the breakdown of chemical structure.

- Viscosity changes: Temperature fluctuations affect fluid flow and atomization.

- Clogging and curing: Premature curing inside the spray equipment can cause blockages.

- Inconsistent coating thickness: Thermal inconsistencies lead to poor finish quality.

When selecting a spray gun for these materials, it is essential to consider how the device manages heat throughout the process.

Essential Features of Spray Guns for Heat-Sensitive Materials

Precise Temperature Control

Spray guns tailored for heat-sensitive materials incorporate temperature regulation to ensure the coating remains within safe limits. Some models include cooled fluid passages or dual-circuit cooling systems that prevent the material from overheating.

Optimal Atomization Technology

Atomization refers to breaking liquid into fine droplets to form a uniform spray pattern. For heat-sensitive materials, fine control over atomization ensures gentle handling of material, minimizing shear stress that could affect the material integrity.

Non-Metallic Material Contact Surfaces

Spray guns designed for sensitive coatings often feature non-metallic internal parts or advanced coatings on surfaces to prevent chemical reactions or overheating caused by friction or metal contact.

Ease of Cleaning and Maintenance

Given the risks of curing or hardening within the nozzle, quick disassembly and cleaning are crucial to maintain consistent performance and prevent downtime.

Types of Spray Gun Units Suitable for Heat-Sensitive Materials

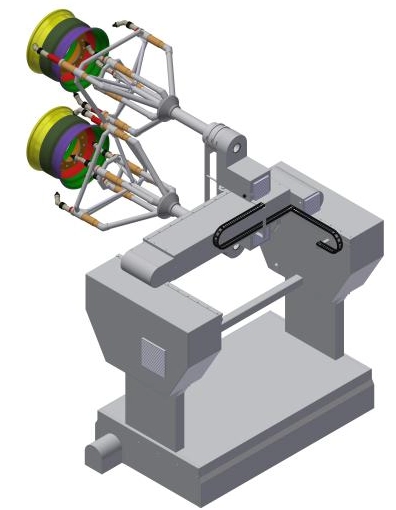

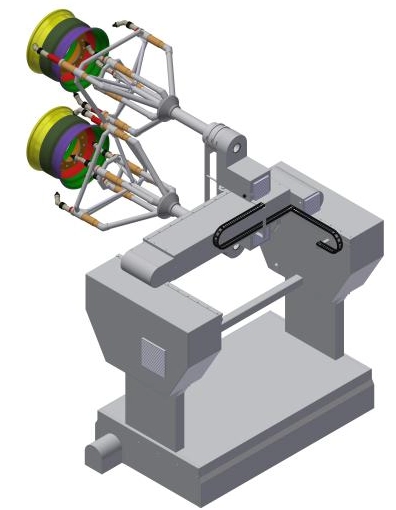

Air-Assisted Airless Spray Guns

These guns combine high-pressure spraying with compressed air to achieve fine atomization at lower temperatures. The process reduces the thermal impact on materials, making it suitable for heat-sensitive coatings.

- Advantages:

- Reduced temperature rise in fluid.

- Better control over spray pattern.

- Less overspray and wastage.

- Drawbacks:

- Requires both high-pressure pump and compressed air supply.

- More complex equipment setup.

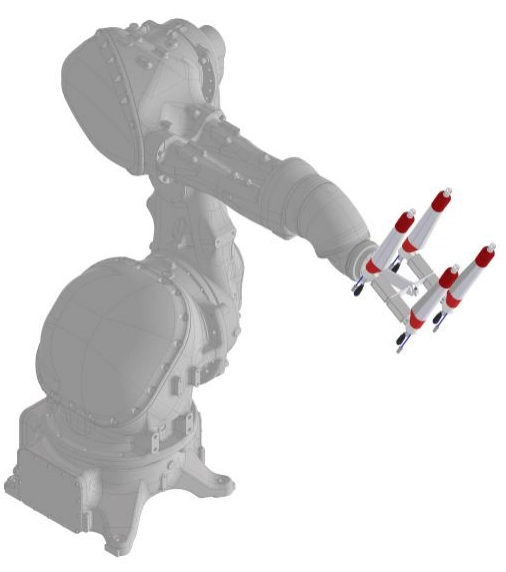

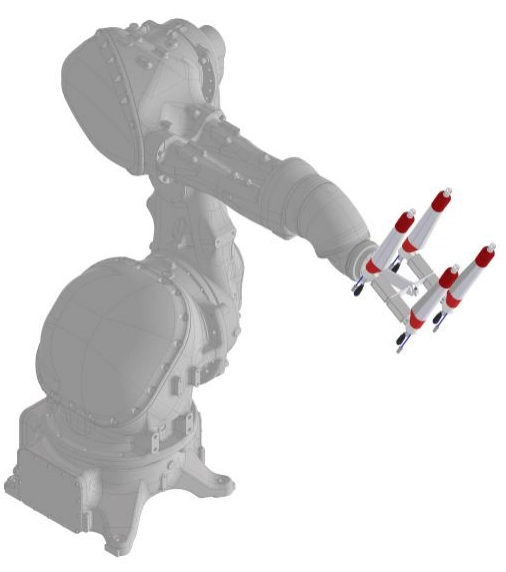

Electrostatic Spray Guns

Electrostatic spraying imparts an electric charge to the particles resulting in better material transfer efficiency. This method works well with heat-sensitive powders and liquid materials where heat buildup must be minimized.

- Advantages:

- Lower material usage.

- Minimal thermal impact.

- Uniform coating on complex shapes.

- Drawbacks:

- Requires grounding and safety practices.

- Not all materials can be electrostatically charged.

HVLP (High Volume Low Pressure) Spray Guns

HVLP guns operate at lower pressure, reducing heat generation by friction and shear forces. They provide a gentle spray and are preferred when minimal heat and overspray are required.

- Advantages:

- Lower temperature impact.

- Better control with lower overspray.

- Suitable for delicate coatings.

- Drawbacks:

- Slower application rate.

- May struggle with highly viscous materials.

Cold Spray Guns

Cold spray technology propels particles at supersonic speeds without significant heating, ideal for highly heat-sensitive materials. Though often used for powders and metals, its adaptation for sensitive polymers and coatings is growing.

- Advantages:

- Virtually no thermal degradation.

- Strong adhesion without heat.

- Suitable for fragile substrates.

- Drawbacks:

- Specialized equipment with higher cost.

- Limited to certain material types.

Comparing Popular Spray Gun Units for Heat-Sensitive Materials

| Spray Gun Type | Temperature Control | Atomization Quality | Suitable Material Types | Operational Complexity |

| Air-Assisted Airless | High (uses dual cooling) | Excellent | Low to medium viscosity | Moderate |

| Electrostatic | Moderate (low thermal impact) | Very high | Powders, liquids | Moderate to high |

| HVLP | Moderate (low pressure) | Good | Low viscosity coatings | Low |

| Cold Spray | Excellent (cold particle spray) | Variable (depends on setup) | Highly sensitive powders/polymers | High |

Key Considerations When Choosing the Optimal Spray Gun Unit

Material Compatibility

Check that the spray gun components are compatible chemically and physically with the material. This prevents reactions or damage to the heat-sensitive coating.

Temperature Monitoring and Control

Look for integrated cooling systems or external temperature sensors to monitor material and gun temperature during spraying.

Application Environment

Consider if the spraying will occur in a controlled environment or on-site, which influences the choice between portable units and stationary systems.

Maintenance and Cleaning

Evaluate how often the gun needs cleaning and ease of access to replace parts, since heat-sensitive materials might require frequent cleaning to avoid curing.

Cost and Production Volume

Balance investment cost against production needs. Higher-end technologies like cold spray or electrostatic guns may have higher upfront costs but reduce material waste and improve quality.

Practical Tips for Spraying Heat-Sensitive Materials

Practical Tips for Spraying Heat-Sensitive Materials

- Use chilled or temperature-controlled supply tanks to maintain low temperatures in feed materials.

- Adjust air and fluid pressures carefully to minimize frictional heat.

- Regularly clean the nozzle and fluid pathways to prevent buildup and blockages.

- Optimize spray distance to reduce heat accumulation on the substrate.

- Test spray parameters on small samples before full-scale production.

Identifying the Best Spray Gun Unit: Case Examples

Case 1: Medical Device Coatings

A medical device manufacturer required a spray gun to apply biocompatible polymer coatings sensitive to temperature. An air-assisted airless spray gun with temperature-controlled fluid lines was chosen. This setup maintained coating integrity and met strict regulatory standards.

Case 2: Food-Grade Packaging

In food packaging, coatings must remain uncontaminated and unaltered by heat. Electrostatic spray guns offered uniform coating with minimal thermal exposure and high transfer efficiency, reducing waste and preserving food safety.

Case 3: Automotive Clear Coats

Automotive clear coats need smooth finishes without thermal damage. HVLP guns provided gentle spray patterns reducing heat and overspray, resulting in superior surface finish and durability.

Frequently Asked Questions

1. Why is temperature control critical when spraying heat-sensitive materials?

Temperature control helps prevent degradation or curing of the material inside the spray gun or on the substrate, preserving its physical and chemical properties.

2. Can any spray gun be used for heat-sensitive materials?

Not all spray guns are suitable; it depends on their design features like cooling systems, pressure settings, and material compatibility.

3. How does HVLP differ from air-assisted airless spraying for sensitive coatings?

HVLP uses low pressure reducing heat but limits flow rates, while air-assisted airless achieves finer atomization with temperature control but is more complex.

4. Is electrostatic spraying safe for all heat-sensitive materials?

Electrostatic spraying is effective but requires materials to be chargeable and involves safety precautions due to high voltages.

5. How often should spray guns be cleaned when used with heat-sensitive coatings?

Cleaning frequency depends on material curing speed but should be performed regularly after each application to prevent clogging.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.