Content Menu

● Understanding the Basics of Coating Techniques

>> What is an Automatic Electrostatic Spray Gun?

>> What is Manual Coating?

● Energy Efficiency in Coating: Core Concepts

>> How Energy is Consumed in Coating Processes

>> Transfer Efficiency and Its Impact

● Energy Efficiency of Automatic Electrostatic Spray Guns

>> Mechanism and Efficiency Advantages

>> Operational Energy Savings

>> Environmental and Cost Benefits

● Energy Efficiency of Manual Coating

>> Flexibility vs. Efficiency

>> Energy Consumption Factors

>> Cost and Environmental Implications

● Comparative Analysis: Automatic Electrostatic Spray Gun vs Manual Coating

● Practical Considerations for Choosing Between Methods

>> Application Environment and Product Type

>> Maintenance and Operational Costs

>> Operator Skill and Training

● Challenges and Limitations

>> Electrostatic Coating Limitations

>> Manual Coating Limitations

● Future Trends in Coating Efficiency

● Frequently Asked Questions (FAQs)

Coating technologies play a crucial role in manufacturing and industrial finishing processes, influencing not only the final quality of products but also costs, energy consumption, and environmental impact. Among the various methods available, automatic electrostatic spray guns and manual coating techniques are prominent choices. This article provides a detailed comparison of the energy efficiency, operational benefits, challenges, and applications of these two coating methods.

Understanding the Basics of Coating Techniques

What is an Automatic Electrostatic Spray Gun?

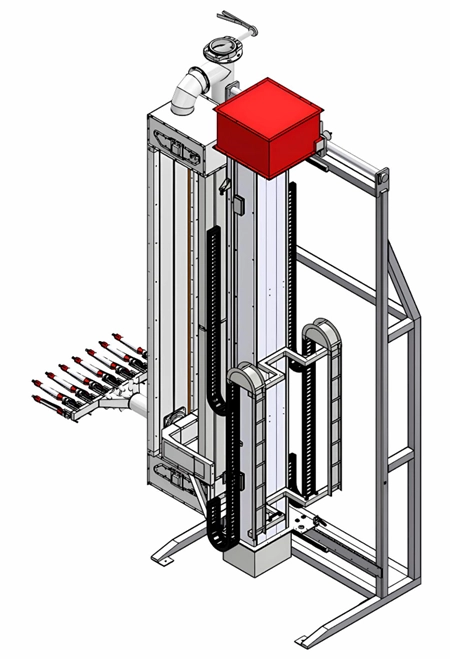

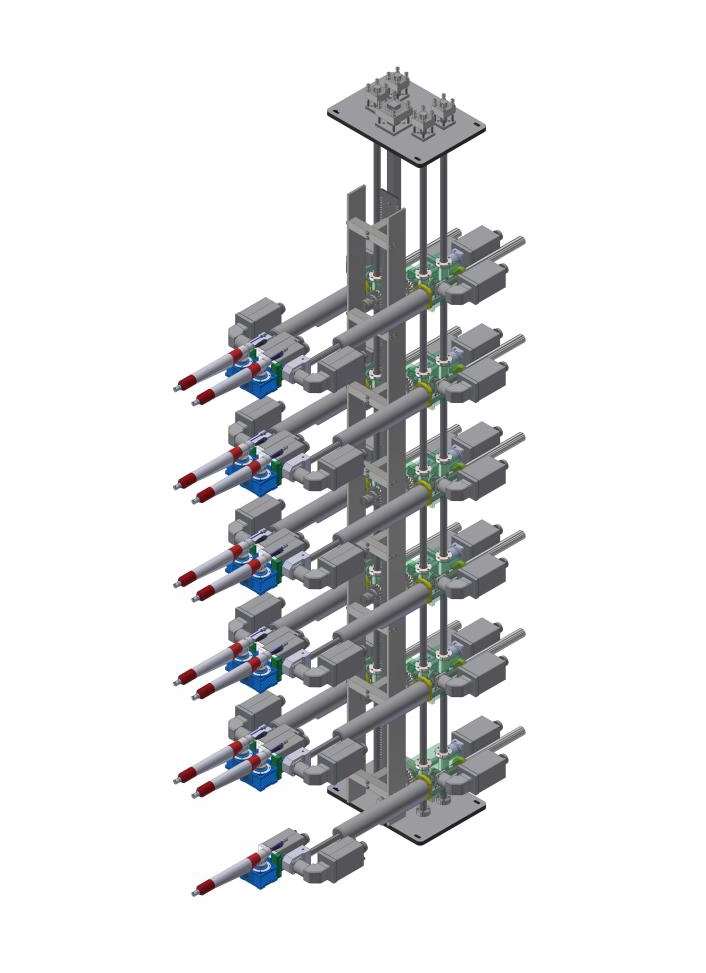

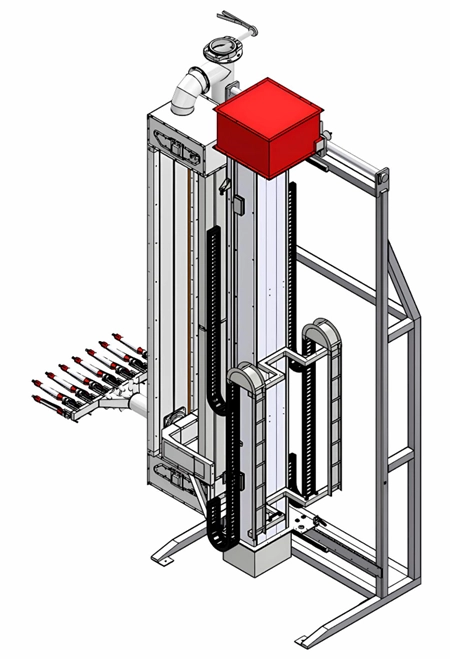

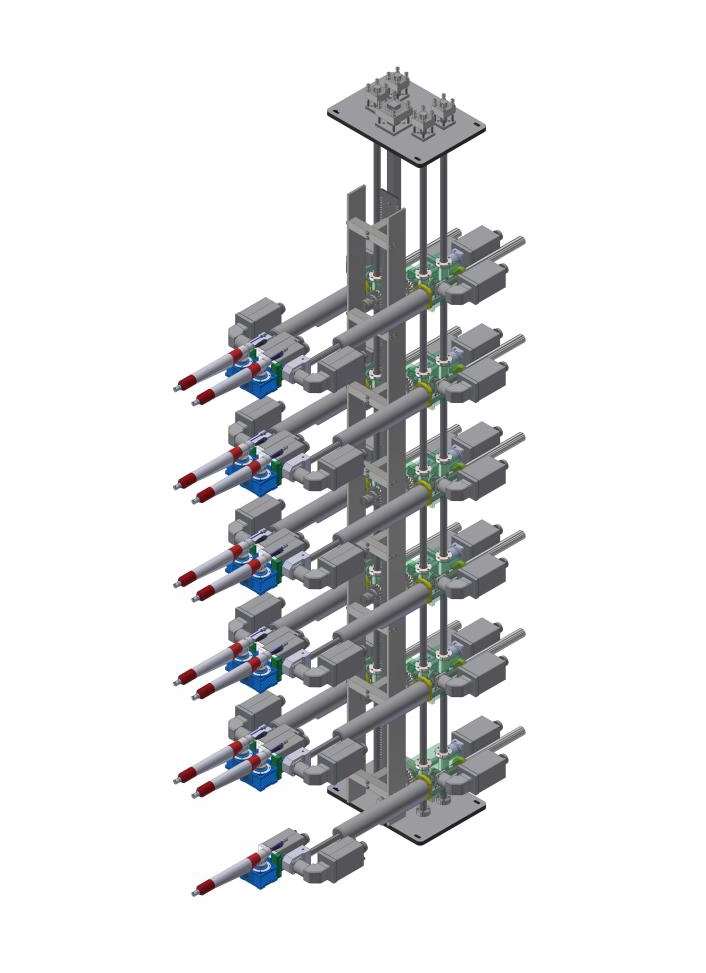

An automatic electrostatic spray gun utilizes high-voltage electrical charges to atomize and apply coatings onto conductive workpieces. By charging the paint particles negatively and grounding the object, the coating particles are attracted and wrap around complex surfaces, achieving uniform coverage with minimal waste. This method is frequently applied in automotive, aerospace, and metal finishing industries due to its precision and efficiency.

What is Manual Coating?

Manual coating refers to applying a coating such as paint or varnish by hand, using either conventional spray guns or brushing. This method is widely used in smaller-scale operations, repairs, or when flexibility for diverse or intricate shapes is necessary. Manual coating depends heavily on operator skill and tends to have higher levels of overspray and material waste.

Energy Efficiency in Coating: Core Concepts

How Energy is Consumed in Coating Processes

Energy consumption in coating involves several factors: the power required to atomize and spray the coating material, the energy for air compression in spray guns, and indirect energy used for curing and drying the applied coating. Minimizing energy use without compromising coating quality is crucial for operational cost savings and reducing environmental footprint.

Transfer Efficiency and Its Impact

Transfer efficiency is the percentage of coating material that successfully adheres to the target surface compared to what is sprayed. A higher transfer efficiency means less wasted paint and less energy spent on producing and handling excess material. This directly influences both the material costs and the energy used throughout the process.

Energy Efficiency of Automatic Electrostatic Spray Guns

Mechanism and Efficiency Advantages

Automatic electrostatic spray guns stand out for their ability to charge coating particles, which increases their attraction to the grounded surfaces—resulting in transfer efficiencies of up to 90-95%. This high transfer efficiency means less overspray, lower material consumption, and reduced energy needed for repainting or rework. The atomization process is also finer and requires less compressed air, lowering energy usage compared to traditional spray methods.

Operational Energy Savings

By automating the spray process, electrostatic guns reduce the time and human labor required. The mechanism requires consistent and controlled atomization, optimizing the coating application for uniform thickness and surface quality. This results in faster production cycles and lower cumulative energy consumption per part coated.

Environmental and Cost Benefits

The improved efficiency reduces volatile organic compounds (VOCs) released during spraying, contributing to better indoor air quality and lower environmental regulatory costs. Additionally, reduced paint usage translates into cost savings for materials and disposal, making electrostatic spraying economically advantageous over time despite higher initial equipment costs.

Energy Efficiency of Manual Coating

Flexibility vs. Efficiency

Manual coating methods provide greater flexibility for irregularly shaped or small-batch products. However, the dependency on manual operation makes transfer efficiency lower, typically ranging between 25-65% depending on the gun and operator skill. This inefficiency results in significant overspray, wasted materials, and excess energy spent on repainting and cleanup.

Energy Consumption Factors

Manual spray guns often require higher air pressure and volume to atomize coatings, increasing compressor energy use. Repetitive manual passes and touch-ups elevate drying and curing energy demands. Moreover, manual labor introduces variability, sometimes causing uneven coatings that require more time and energy to rectify.

Cost and Environmental Implications

Although manual spray guns usually have a lower upfront cost, the extended operational time, higher material waste, and greater energy consumption often lead to increased long-term expenses. Manual coating may also produce more VOC emissions due to overspray, posing potential environmental compliance risks.

Comparative Analysis: Automatic Electrostatic Spray Gun vs Manual Coating

| Aspect | Automatic Electrostatic Spray Gun | Manual Coating |

| Transfer Efficiency | Up to 95% | 25-65% |

| Energy Consumption | Lower due to finer atomization and less compressed air | Higher due to increased air pressure and labor time |

| Material Waste | Minimal overspray | Significant overspray |

| Labor Requirements | Reduced because of automation | Intensive manual labor needed |

| Initial Equipment Cost | Higher | Lower |

| Environmental Impact | Lower VOC emissions, less waste | Higher VOC emissions and waste |

| Surface Coverage Quality | Uniform, wraps around complex shapes | Operator-dependent, variable quality |

| Suitable Materials | Conductive surfaces mostly metals | Wide range including non-conductive materials |

Practical Considerations for Choosing Between Methods

Application Environment and Product Type

Automatic electrostatic spray guns are better suited for large-scale, repetitive production runs involving metal and conductive parts, where energy efficiency and cost savings are priorities. Manual coating fits niche applications, small batches, or non-conductive substrates like wood or plastic, where electrostatic application is limited.

Maintenance and Operational Costs

Though electrostatic guns require higher initial investments and routine maintenance for electrical and mechanical components, the long-term savings in materials, energy, and labor make them cost-efficient. Manual systems, while cheaper initially, can incur higher expenses due to inefficiency and labor costs.

Operator Skill and Training

Electrostatic systems require trained operators for setup and maintenance but reduce dependency on operator skill for consistent results. Manual coating relies heavily on operator expertise to minimize waste and achieve quality finishes but is more prone to variability and rework.

Challenges and Limitations

Electrostatic Coating Limitations

The Faraday cage effect causes difficulty in coating recessed surfaces or cavities evenly with electrostatic methods. Some non-conductive materials require pretreatment or special primers. Initial investment cost and equipment complexity can be barriers for small enterprises.

Manual Coating Limitations

Manual coating faces challenges in achieving consistent quality and efficiency. Larger workforce and longer process times increase energy use indirectly. Overspray and paint waste have environmental and economic consequences.

Future Trends in Coating Efficiency

Technological advancements focus on enhancing electrostatic technology for greater versatility on non-conductive substrates and complex geometries. Integration with robotic automation optimizes precision and repeatability, further reducing energy consumption. Hybrid methods combining electrostatic and manual approaches for specific tasks are also gaining ground.

Frequently Asked Questions (FAQs)

Q1: What types of coatings can be applied using automatic electrostatic spray guns?

A1: They are suitable for solventborne coatings, powder coatings, and certain waterborne coatings that can hold an electrostatic charge, mainly on conductive metal surfaces.

Q2: Can electrostatic spray guns be used on plastic or wood surfaces?

A2: Electrostatic spray guns are less effective on non-conductive materials unless a conductive primer is applied first to enable charging.

Q3: How much energy can be saved using an automatic electrostatic spray gun compared to manual coating?

A3: Energy savings vary by application but can be significant due to higher transfer efficiency, less overspray, reduced compressed air use, and faster processing times.

Q4: Is the initial cost of automatic electrostatic spray equipment justified?

A4: Despite higher upfront costs, the long-term savings in material, labor, and energy often result in a positive return on investment.

Q5: What are the environmental benefits of using electrostatic spray guns?

A5: They reduce VOC emissions by minimizing overspray, lower material waste, and improve air quality in the working environment.

[1](https://www.hdaspraygun.com/wap/news-detail-247.html)

[2](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/advantages-of-spraying-with-electrostatic-guns.html)

[3](https://www.decc.com/recent-articles/hvlp-spray-vs-electrostatic-spray/)

[4](https://www.cetinc.com/should-i-be-using-electrostatic-spray/)

[5](https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/conventional-vs-electrostatic-spray-guns.html)

[6](https://www.wagner-group.com/us/industry/products/liquid-coating/applying/)

[7](https://www.ramseierkoatings.com/which-offers-better-efficiency-electrostatic-vs-traditional-spray-guns.html)

[8](https://www.ramseierkoatings.com/automatic-electrostatic-spray-gun-vs-manual-spray-gun-which-is-better-for-your-production-line.html)

[9](https://www.codinter.com/en/electrostatic-vs-conventional-painting-which-process-is-better/)

[10](https://ai.otson.com/surface-coating-technology-overview-electrostatic-spray-coating-technologies/)

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.