Content Menu

● Understanding the basics of electrostatic spraying

● Why small batches benefit from manual operation

● Core components of a manual electrostatic spray system

● How they differ from conventional spray guns

● Key advantages for small-batch applications

● Potential limitations to consider

● Best practices for setup and calibration

● Surface preparation for best results

● Choosing the right coatings

● Troubleshooting common issues

● Safety guidelines and protective measures

● Workflow ideas for small-batch producers

● Maintenance and longevity tips

● Cost considerations and value proposition

● Real-world examples and use cases

● Getting started: a practical checklist

● FAQ: common questions about manual electrostatic spray guns

● Practical guidelines for optimizing performance

● Closing thought

Manual electrostatic spray guns have carved out a vital niche in the world of coating applications, especially for small batch projects. They combine portability, precision, and cost-effectiveness in a way that makes them attractive to hobbyists, small businesses, and bespoke manufacturers alike. This article explores why these tools are so well-suited to limited-run coatings, how they work, key advantages and limitations, best practices, and practical tips to maximize results.

Understanding the basics of electrostatic spraying

Electrostatic spraying uses the principle of electrical attraction to deposit charged paint particles onto a grounded object. As the spray atomizes the coating into tiny droplets, an electric field charges them. The charged droplets are drawn to the surface, wrapping around edges and corners to produce a uniform, high-build finish with minimal overspray. Manual variants rely on human operation to control the trigger, nozzle distance, and spray pattern, while the instrument handles the electrical charge and atomization process.

Why small batches benefit from manual operation

Small batch coating projects often demand flexibility, rapid setup, and the ability to switch between colors or substrates. Manual electrostatic spray guns provide several advantages in these scenarios:

- Quick readiness: Set up and calibration are straightforward, enabling you to start coating without lengthy preparation.

- Versatility: One tool can handle a range of job sizes, shapes, and materials with simple adjustments.

- Cost efficiency: Lower initial investment and maintenance costs relative to automatic systems make them accessible for limited runs.

- Precision control: The operator's tactile feedback enables careful guidance of complex geometries and delicate substrates.

Core components of a manual electrostatic spray system

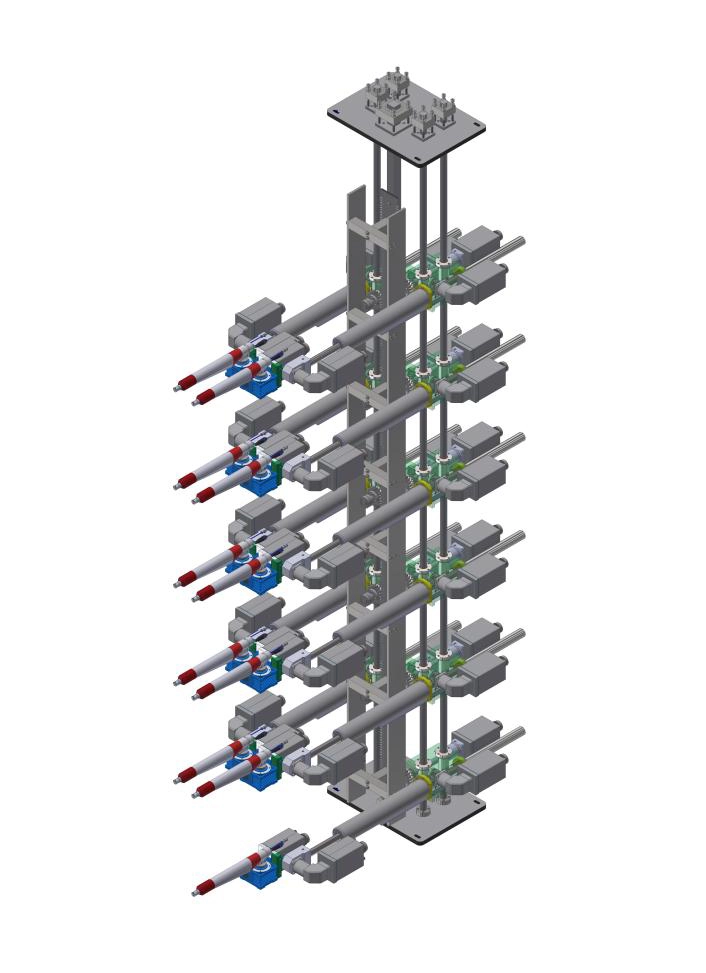

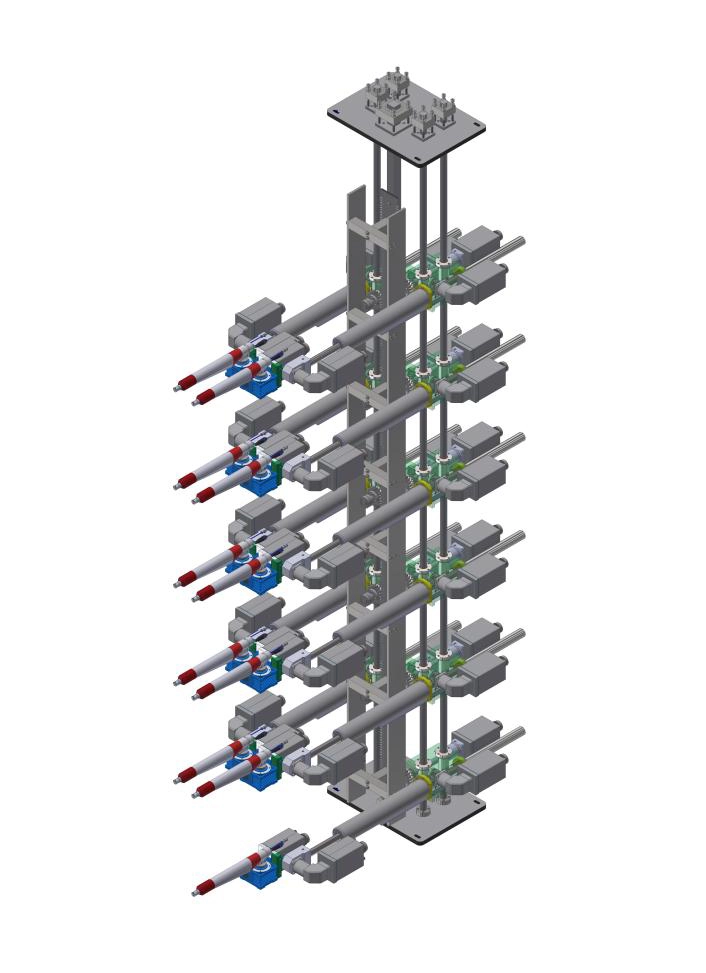

A typical hand-held electrostatic spray setup includes:

- Spray gun with adjustable nozzle and fluid control

- High-voltage power supply or control unit

- Grounding mechanism for the workpiece

- Air supply and regulator (for atomization and pattern control)

- hoses and connectors with appropriate insulation

Understanding how these components interact helps you diagnose issues and optimize performance for small-batch work.

How they differ from conventional spray guns

Compared with traditional air-atomized or HVLP spray guns, manual electrostatic variants emphasize charge-assisted deposition. The added electrical field improves transfer efficiency, reduces overspray, and enhances coating uniformity on irregularly shaped objects. However, they require careful handling of high voltage, proper grounding, and compatible coatings to achieve optimal results.

Key advantages for small-batch applications

- High transfer efficiency: Electrostatic attraction directs more coating to the surface, reducing waste and cleanup.

- Edge and contour coverage: The field encourages coating to wrap around complex geometries, which is beneficial for parts with corners or recesses.

- Material savings: Reduced overspray translates to lower material costs per part.

- Scalability for prototyping: You can test finishes on few units without committing to large runs.

- Easy color changes: Quick cleaning and color swapping support frequent design iterations.

Potential limitations to consider

- Surface charging requirements: Non-conductive or poorly grounded parts can hinder performance.

- Material compatibility: Some coatings may require specific solvents or formulations to maintain electrical properties.

- Operator skill: Consistent results rely on steady hand control and disciplined technique.

- Environment sensitivity: Temperature, humidity, and ventilation can influence atomization and cure.

- Safety considerations: High voltage demands careful setup and protective measures.

Best practices for setup and calibration

- Ensure proper grounding: Confirm that the workpiece is adequately grounded and that the charge path is uninterrupted.

- Clean and prep surfaces: Dust, oil, and residues disrupt coating adhesion and electrical flow.

- Choose compatible materials: Use coatings formulated for electrostatic spray to maintain charge stability.

- Optimize operating distance: Find the sweet spot where electrical field strength and spray pattern yield uniform coverage.

- Manage ventilation: Provide adequate exhaust to capture overspray and fumes, protecting the operator and environment.

- Calibrate flow and pattern: Adjust fluid pressure and air settings to achieve consistent atomization and a steady spray fan.

Surface preparation for best results

Proper surface preparation is critical for electrostatic coating success, particularly in small batches where rework is costly. Steps typically include surface cleaning, degreasing, sanding or abrading for adhesion, and, if necessary, applying a compatible primer. For plastics or problematic substrates, surface treatment or adhesion promoters can dramatically improve film build and impact resistance.

Choosing the right coatings

Not all coatings behave well in electrostatic spray. Consider the following when selecting materials:

- Viscosity and pot life: Coatings should flow smoothly through the nozzle without clogging, with a workable pot life after mixing.

- Conductivity: Some formulations are engineered to maintain charge; others may dissipate charge too quickly.

- Cure mechanism: Depending on the formulation, you may need specific curing temperatures or environmental conditions.

- Color stability and finish: Polymers, pigments, and clear coats affect gloss, citrus resistance, and UV stability.

Troubleshooting common issues

- Poor adhesion: Revisit surface prep, primer compatibility, and cure conditions. Ensure proper grounding and charger integrity.

- Orange peel or texture: Adjust nozzle size, fluid pressure, and air cap settings. Warmer conditions can also improve flow.

- Uneven coverage: Reassess distance, pattern, and movement speed. Slow, uniform passes typically yield better results.

- Electric arcing or sparks: Inspect insulation, cables, and connections. Do not operate if there are damaged wires.

- Excessive overspray: Verify ground path, charge balance, and spray angle. Consider adjusting the charge intensity or reducing spray velocity.

Safety guidelines and protective measures

- High voltage awareness: Treat the system as a high-voltage device; use insulated PPE and avoid contact with exposed parts.

- Ventilation: Operate in well-ventilated spaces or use fume extraction to control airborne particulates and solvents.

- Grounding discipline: Maintain secure grounding to prevent stray charges and electrical hazards.

- Personal protection: Wear appropriate respirators, gloves, and eye protection in line with coating materials used.

- Maintenance schedule: Regularly inspect hoses, seals, and nozzles for wear; replace worn components promptly.

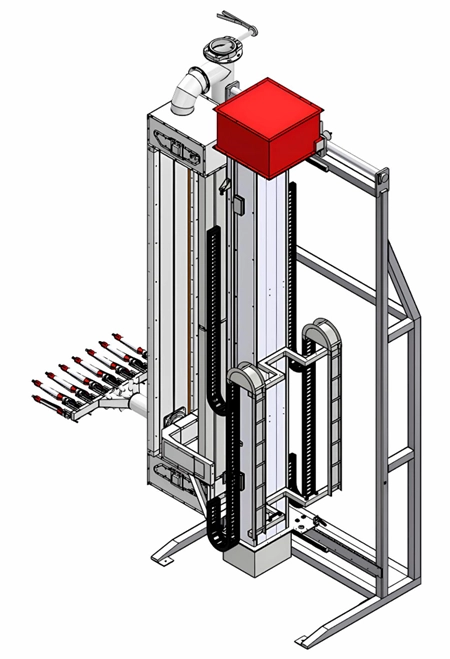

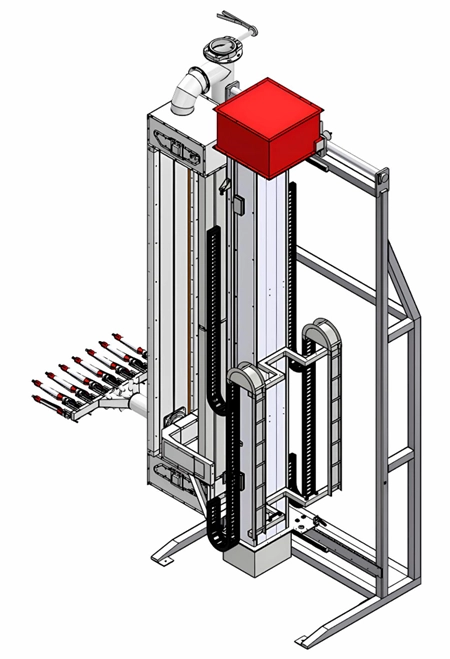

Workflow ideas for small-batch producers

- Rapid prototyping line: A compact setup can complete a handful of parts with different finishes in a single session.

- Batch customization: Produce small runs with individualized colors or finishes without retooling large portions of production.

- Coating over multiple materials: With proper surface prep, the same system can handle metals, plastics, and composites, enabling versatile product lines.

- Finishing for prototypes: Achieve professional finishes on concept samples, accelerators for customer feedback, and marketing materials.

Maintenance and longevity tips

- Regular cleaning: Prevent pigment settling and nozzle clogging by cleaning after each session.

- Use compatible cleaners: Select solvents and degreasers that won't degrade seals or insulation.

- Inspect seals and gaskets: Replace worn parts that may cause air leaks or loss of atomization quality.

- Store properly: Keep components dry and protected from dust when not in use.

Cost considerations and value proposition

Manual electrostatic spray guns generally offer a lower entry price compared with automatic systems, while still delivering high-quality finishes. For small businesses or hobbyists, this balance of affordability and performance is a compelling reason to invest. Ongoing costs include coatings, replacement parts, power supply maintenance, and consumables like nozzle caps and filters. When used for the right applications, the return on investment comes from material savings, faster turnarounds, and the ability to deliver customized finishes.

Real-world examples and use cases

- Custom automotive trim parts: Small batches of bespoke components benefit from precise edge coverage and reduced overspray.

- Appliance touchpoints: Coatings on control panels and handles can be applied efficiently in low-volume runs.

- Prototyping for consumer electronics: Finishes with uniform gloss and color depth improve early-stage product evaluation.

- Furniture components: Small makers can achieve durable finishes on irregular surfaces without investing in full-scale production lines.

Getting started: a practical checklist

- Define the project scope: Part count, required finishes, and color changes.

- Assess substrate compatibility: Metal, plastic, or composite parts may behave differently under electrostatic spray.

- Set a budget and timeline: Plan for standard consumables, maintenance, and potential upgrades.

- Source a suitable manual electrostatic spray gun: Look for a model with adjustable voltage, reliable grounding, and a comfortable grip.

- Establish safety protocols: Create a clear set of rules, PPE, and ventilation standards.

- Pilot test: Run a small batch to validate adhesion, finish quality, and cure.

FAQ: common questions about manual electrostatic spray guns

- How does an electrostatic spray gun differ from a conventional spray gun?

- What substrates work best with manual electrostatic spray guns?

- How can I improve transfer efficiency during a small batch run?

- What maintenance steps are essential for longevity?

- Are there coatings that should not be used with electrostatic spray?

- How does an electrostatic spray gun differ from a conventional spray gun? An electrostatic spray gun uses an electrical charge to attract paint particles to the surface, improving deposition efficiency and coverage, especially on complex geometries.

- What substrates work best with manual electrostatic spray guns? Conductive or properly grounded surfaces, including metals and some plastics with suitable primers, respond well; ensuring proper grounding is essential for non-conductive substrates.

- How can I improve transfer efficiency during a small batch run? Use compatible coatings, optimize nozzle size and flow, adjust the distance and movement speed, and ensure proper grounding and charge balance.

- What maintenance steps are essential for longevity? Regular cleaning, inspecting seals and hoses, replacing worn components, and using compatible cleaners and solvents.

- Are there coatings that should not be used with electrostatic spray? Coatings that poorly retain charge, have current-sensitive formulations, or require solvents incompatible with the equipment's materials should be avoided unless specifically designed for electrostatic use.

Practical guidelines for optimizing performance

- Start with a controlled pilot: Run a few test pieces to calibrate charging, flow, and pattern before committing to a full batch.

- Keep environments consistent: Stabilize temperature and humidity to minimize variability in coating behavior.

- Document settings: Record voltage, fluid pressure, nozzle size, and air settings for repeatability in future batches.

Closing thought

Manual electrostatic spray guns offer a compelling blend of precision, flexibility, and cost efficiency for small batch coating projects. By understanding how the system works, following best practices, and carefully selecting compatible materials, operators can achieve professional finishes without the overhead of large-scale automated equipment.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.