Content Menu

● Understanding the electrostatic spray process

● Key metrics to compare

● Leading brands and how they differ

● How to choose based on your application

● Material compatibility and coatings

● Maintenance practices that extend life

● Ergonomics and operator comfort

● Cost considerations

● Practical testing steps

● Real-world considerations

● Summary of strengths by category

● Practical recommendations by user type

● Common pitfalls to avoid

● Industry trends to watch

● Benefits of standardizing on a single brand

● Final thoughts

● Questions and Answers

Manual electrostatic spray guns have transformed small to mid-scale finishing projects by delivering efficient, high-quality coatings with reduced waste. When selecting a spray gun, professionals weigh factors such as atomization quality, electrostatic charge efficiency, material compatibility, ergonomics, maintenance, and total cost of ownership. This article examines leading brands, their standout models, and practical considerations to help you decide which manual electrostatic spray gun best suits your needs.

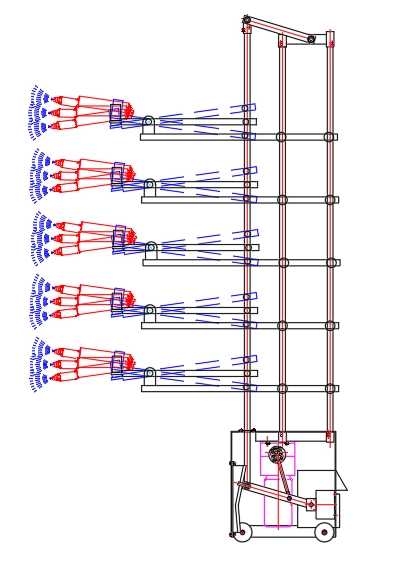

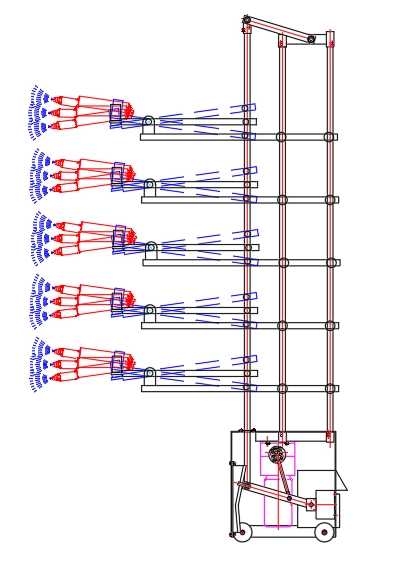

Understanding the electrostatic spray process

Electrostatics works by imparting an electric charge to the coating particles as they exit the nozzle. The charged particles are attracted to grounded or oppositely charged surfaces, resulting in improved transfer efficiency, reduced overspray, and more uniform coverage on complex geometries. The process is especially beneficial for automotive refinishes, agricultural equipment, consumer goods, and industrial components with recesses and intricate shapes.

Key metrics to compare

When evaluating manual electrostatic spray guns, consider:

- Transfer efficiency: percentage of coating that adheres to the part versus wasted as overspray.

- Atomization quality: how finely the coating droplet is broken up for even coverage.

- Charge consistency: stability of the electrostatic field during spraying.

- Fluid delivery and pattern control: adjustable flow rates, fan width, and spray pattern consistency.

- Ergonomics and weight: handle comfort, balance, and ease of use during long sessions.

- Material compatibility: ability to spray different coatings, including UV-curable, waterborne, solvent-based, and metallics.

- Maintenance and durability: ease of cleaning, nozzle wear, and reliability under demanding conditions.

- Total cost of ownership: purchase price, consumables, power consumption, and maintenance needs.

Leading brands and how they differ

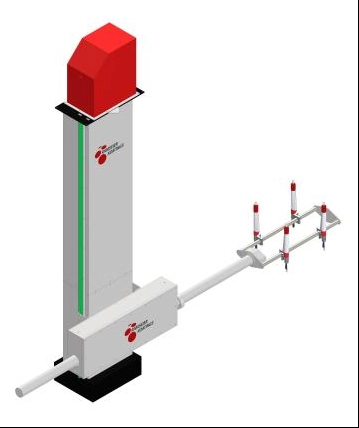

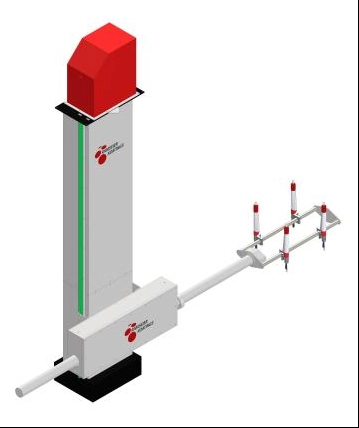

Brand A emphasizes lightweight ergonomics and a modular nozzle system that simplifies color changes and maintenance. Their brushless control electronics provide smooth start-up and consistent charge levels, making it a solid choice for users who spray a broad range of materials but value precision above all.

Brand B prioritizes high-voltage stability and robust electrostatic optimization. The gun ships with a digital interface that displays live feedback on charge density and flow rate, aiding technicians who demand precise repeatability and traceability in quality control.

Brand C focuses on versatility for automotive and industrial finishes, offering interchangeable atomizers and spray patterns. The design accommodates both high- and low-viscosity coatings, allowing users to tailor their setup to the material at hand without swapping guns.

Brand D targets value-conscious buyers who still require solid performance. Their models emphasize durability, straightforward maintenance, and lower-priced consumables. This makes Brand D appealing for startups, schools, and small shops.

Brand E showcases an emphasis on surface quality, with advanced nozzle geometries and optimized powder-for-coating compatibility for certain bespoke finishes. They deliver excellent finish uniformity, particularly on challenging geometries, but at a premium price point.

Note: Specific model names and technical specifications vary by region and product line. When selecting a unit, verify availability of replacement parts, local service support, and warranty terms.

How to choose based on your application

- Automotive refinishing and collision repair: Seek models with stable charge performance at high spray speeds, excellent atomization for metallics, and reliable cleaning routines to prevent clogging from pigments.

- Furniture and cabinetry: Prioritize consistent pattern control and minimal overspray to maximize coverage on flat and curved surfaces while preserving finish quality.

- Medical device or consumer electronics components: Consider models with precise control over flow and a cleanable design to meet strict cleanliness standards.

- Small shops and hobbyists: Look for affordable options with easy maintenance, readily available consumables, and good long-term reliability.

Material compatibility and coatings

Electrostatic spray guns must handle a range of coatings, including:

- Waterborne architectural and furniture finishes

- Solvent-based primers and topcoats

- UV-curable coatings with short drying cycles

- Metallics and pearls that require careful atomization to prevent mottling

- Epoxies and polyurethanes used in industrial applications

Before committing, test a coating sample through the gun to assess spray behavior, gloss, and adhesion. For UV-curable systems, pay attention to curing speed and surface tack during initial handling.

Maintenance practices that extend life

- Regular nozzle and needle cleaning after each use; avoid dried pigment buildup.

- Use recommended cleaners compatible with the coating type to protect seals and o-rings.

- Inspect air supply and filtration to ensure consistent atomization and avoid air contaminants entering the coating.

- Schedule periodic service checks for the high-voltage supply and trigger electronics.

- Store devices in a controlled environment to prevent corrosion or degradation of seals.

Ergonomics and operator comfort

Long spraying sessions benefit from:

- Balanced weight distribution and a comfortable forearm grip

- Soft-touch trigger with progressive resistance for precise control

- Readable gauges or digital readouts indicating flow rate and charge level

- Intuitive adjustments for spray pattern, fan width, and material viscosity

Cost considerations

- Initial purchase price: higher-end models may offer better durability and longer-term savings.

- Consumables: nozzle tips, seals, and replacement electrodes contribute to recurring costs.

- Training and support: access to technical service and user manuals reduces downtime.

- Energy usage: most manual electrostatic guns are powered by the aerosol air supply, with some models drawing power for electronics; consider overall energy consumption.

Practical testing steps

- Conduct side-by-side trials with the same coating on identical test panels.

- Evaluate transfer efficiency by weighing panels before and after coating.

- Inspect for color consistency, gloss, and surface defects under standard lighting.

- Check pattern stability across multiple passes and at different distances.

- Assess ease of cleaning and maintenance after each test run.

Real-world considerations

- Environmental conditions matter. Temperature, humidity, and dust can influence spray behavior and electrostatic performance.

- Operator skill plays a significant role. Allow time for users to calibrate equipment and understand their coatings' rheology.

- Safety is essential. Ensure proper grounding, proper ventilation, and the use of personal protective equipment when working with solvents or hazardous coatings.

Summary of strengths by category

- Best for overall balance: Models with stable charge performance, reliable atomization, and easy maintenance.

- Best for precision: Systems offering advanced electronic feedback and fine-grained control over charge and flow.

- Best for value: Durable designs with straightforward maintenance and affordable consumables.

- Best for coatings variety: Flexible atomizers and spray patterns suitable for a wide range of materials.

- Best for finish quality: Nozzle geometries and charge optimization that yield uniform, defect-free surfaces.

Practical recommendations by user type

- For a shop expanding into automotive refinishing: Invest in a model with robust charge stability, compatibility with metallics, and easy cleaning routines.

- For a university lab or training facility: Choose cost-effective, durable units with straightforward operation to maximize hands-on learning.

- For a boutique furniture maker: Prioritize pattern control, minimal overspray, and ease of maintenance to uphold a high-quality finish on interior and exterior pieces.

- For a startup fabricator: Consider models with lower upfront costs and abundant replacement parts, then scale up as demand grows.

Common pitfalls to avoid

- Overestimating transfer efficiency without validating with real-world tests on your parts.

- Choosing a gun that cannot handle your most challenging coatings, leading to ribboning or mottling.

- Neglecting maintenance; clogged nozzles and degraded seals reduce performance dramatically.

- Ignoring ergonomic comfort, which can reduce workflow efficiency and increase fatigue.

Industry trends to watch

- Increased emphasis on digital feedback and closed-loop control for spray quality.

- Advancements in nozzle design that improve atomization for metallics and pearls.

- More modular systems enabling easier upgrades and parts replacement.

- Sustainable materials and cleaner maintenance solutions to reduce downtime and waste.

Benefits of standardizing on a single brand

- Consistent workflow and reduced learning curves for technicians.

- Easier procurement of replacement parts and consumables.

- Potential improvements in service and warranty coverage with a single supplier.

Final thoughts

Manual electrostatic spray guns remain a versatile choice for a wide range of applications. By evaluating transfer efficiency, atomization quality, charge stability, coating compatibility, ergonomics, and total ownership costs, you can identify a brand and model that deliver reliable results for your specific needs. Practical testing and a careful consideration of maintenance requirements will pay dividends in finish quality, process efficiency, and overall productivity.

Questions and Answers

1) What is the transfer efficiency of an electrostatic spray gun, and why is it important?

Transfer efficiency is the percentage of coating that actually adheres to the workpiece. Higher transfer efficiency means less paint is wasted in overspray, ultimately leading to lower costs and more uniform coating distribution.

2) What are the key factors influencing spray gun atomization?

The spray gun's feed rate, atomizing nozzle geometry, paint viscosity, surface charge, and air pressure all affect atomization.

3) How should I choose a spray gun suitable for metal coatings?

Prioritize models that offer stable charging performance, are compatible with metallic pearlescent effects, and are easy to clean and maintain. This ensures they can maintain a stable charge and good atomization even at high spray speeds.

4) What are the best practices for cleaning and maintenance?

Clean the nozzle, needle valve, and seals after each use. Regularly maintain high-voltage power supply components with a cleaning agent compatible with the coating. Store in a controlled environment to prevent corrosion.

5) What comparative tests should I conduct before purchasing? Comparisons were made using the same coating on the same batch of test pieces, evaluating transfer efficiency, coating uniformity, gloss, and surface defects, while also noting pattern stability and ease of maintenance.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.