Content Menu

● Understanding the Basics: What Makes Manual Electrostatic Spray Guns Cost-Effective

● Transfer Efficiency: The Primary Path to Lower Material Costs

● Labor Productivity: Speed Without Sacrificing Quality

● Waste Reduction: Turning Scraps into Savings

● Energy and Cure Time: Indirect Cost Implications

● Maintenance and Durability: Long-Term Cost Control

● Process Control: The Role of Settings and Workflows

● Material Selection: Matching Powder Properties to Business Goals

● Case Scenarios: Practical Outcomes in Real-World Plants

● Best Practices: Quick Wins to Start Saving Today

● When to Consider Alternatives: Limitations of Manual Electrostatic Spray Guns

● Summary of Cost-Saving Pathways

● Practical Implementation Checklist

● Frequently Asked Questions

● Conclusion

Powder coating offers superior corrosion resistance, durability, and aesthetic appeal for a wide range of products. However, the cost of powder coating can squeeze margins if not managed carefully. Manual electrostatic spray guns present a practical, cost-effective solution for many coating operations, especially in small to mid-sized facilities, job shops, or on-site applications. This article explores how manual electrostatic spray guns can help you cut costs without compromising coating quality, through material efficiency, labor productivity, waste reduction, and smarter process control.

Understanding the Basics: What Makes Manual Electrostatic Spray Guns Cost-Effective

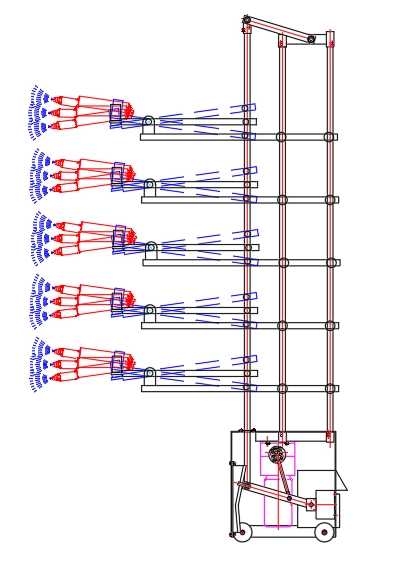

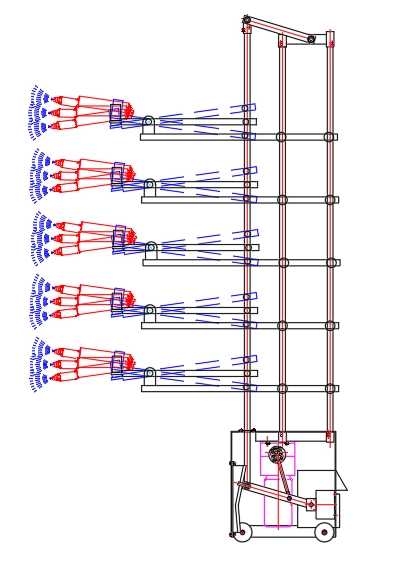

Manual electrostatic spray guns work by imparting a static charge to powder particles, which are then attracted to the grounded or oppositely charged substrate. The result is improved transfer efficiency, reduced overspray, and uniform film build. When used properly, these tools can lower coating thickness variability, cut material waste, and shorten cycle times. The cost benefits arise from several interrelated factors:

- Transfer efficiency: More powder adheres to the part and less becomes waste.

- Application efficiency: Consistent spray patterns reduce rework and rejects.

- Labor efficiency: Faster set-ups and fewer passes can shorten production time.

- Maintenance costs: Robust guns with proven wear parts can lower long-term maintenance expenses.

Transfer Efficiency: The Primary Path to Lower Material Costs

A key advantage of electrostatic spray is the potential for higher transfer efficiency. By charging powder particles, the atoms are drawn toward the surface with less bounce and run-off. In practice, this means:

- Reduced overspray: Less powder dries and sifts away, eliminating the need to repurchase material.

- Thinner, even coats: Fewer layers may be required to achieve the desired finish, saving material and curing energy.

- Consistent coverage on complex geometries: Intricate parts that previously required masking or extra passes can be coated more efficiently.

To maximize transfer efficiency, operators should select the appropriate nozzle size, maintain correct voltage settings within the gun's design range, and adjust air flow to create a stable, atomized spray. Periodic inspection of powder flow, regulator cleanliness, and hose integrity helps prevent subtle losses in efficiency.

Labor Productivity: Speed Without Sacrificing Quality

Manual spray guns enable operators to apply powder with a tactile, controlled motion. When used correctly, this can translate into:

- Faster setup and changeovers: Quick adjustments for batch changes reduce downtime.

- Fewer reworks: Even coverage lowers the incidence of runs, orange peel, and thin spots that require re-coating.

- Training-to-output alignment: Operators can reach productive speeds with proper coaching and standard work instructions.

Investing in training and clear guidelines for spray technique—such as consistent gun distance, arm speed, and coat thickness targets—pays back through higher throughput and fewer interruptions.

Waste Reduction: Turning Scraps into Savings

Powder management is a significant contributor to total coating costs. Manual electrostatic gun systems support waste reduction in several ways:

- Reclaimable overspray: In many systems, unused powder can be reclaimed with a cyclone or reclaiming unit and returned to the hopper.

- Reduced dust generation: Proper containment and controlled spray reduce airborne fines, improving workplace safety and reducing material loss.

- Efficient reclaim for re-coating: Parts with small defects or touch-ups can be recharged and coated again, minimizing discarded material.

To optimize waste reduction, implement a closed-loop reclaim system, maintain seals and gaskets to avoid powder leakage, and establish a routine for cleaning filters and cyclone collectors.

Energy and Cure Time: Indirect Cost Implications

Although curing energy and cycle times depend on powder type and the coated substrate, smaller or more uniform film builds often enable faster cure cycles and lower energy consumption per kilogram of coated part. Manual spray guns, when paired with proper particle control, can help you avoid excessive coating that requires longer cure times. This is particularly valuable for high-throughput plants or facilities with strict energy budgets.

Maintenance and Durability: Long-Term Cost Control

Cost savings extend beyond the purchase price of powder and electricity. Well-maintained equipment minimizes downtime and prolongs service life. Consider these maintenance practices:

- Regular nozzle and orifice inspection: Worn nozzles degrade powder flow and coverage.

- Hose and connection checks: Leaks cause powder loss and inconsistent deposition.

- Gun and controller calibration: Periodic voltage and current checks maintain consistent performance.

- Air supply quality: Clean, regulated air ensures stable spray and reduces component wear.

Choosing rugged, serviceable components with widely available spare parts helps keep maintenance costs predictable and manageable.

Process Control: The Role of Settings and Workflows

Effective cost reduction with manual electrostatic spray guns hinges on disciplined process control. Key control levers include:

- Powder particle size and flow rate: Fine powders can improve finish quality but may require careful handling to avoid streamers or matting.

- Voltage and current optimization: The electrostatic charge level affects deposition efficiency and pull-in force.

- Grounding quality: Proper grounding of the substrate avoids arcing and inconsistent coating.

- Distance and travel speed: A consistent application pattern reduces variability and overspray.

- Part geometry awareness: Complex shapes benefit from stencil strategies or strategic pre-coating to ensure coverage.

Documented standard operating procedures (SOPs), operator checklists, and visual guides help ensure processes remain repeatable and cost-effective.

Material Selection: Matching Powder Properties to Business Goals

Not all powders are created equal when it comes to cost performance. Considering costs holistically involves:

- Powder utilization rate: Some powders reclaim well, others may degrade with reuse.

- Flowability and recoat-ability: Powders that flow smoothly reduce clogs and waste.

- Cure compatibility: Matching curing temperatures to substrate limits prevents waste due to warping or defects.

- Supplier terms: Bulk purchase agreements, return policies for unused material, and lot traceability can affect total cost.

When evaluating powder, consider total cost of ownership, not just the per-kilogram price.

Case Scenarios: Practical Outcomes in Real-World Plants

- Small workshop upgrading from manual non-electrostatic to manual electrostatic spray: Expect noticeable reductions in overspray, improved surface uniformity, and faster cycle times, leading to lower material waste and higher throughput.

- Mid-sized factory with diverse product lines: Implement targeted nozzle and travel-speed adjustments to optimize coating for varying geometries, achieving better coverage with less material and fewer passes.

- On-site or mobile coating services: Portable manual electrostatic spray guns enable consistent finishes on-site, reducing travel time and rework, and enabling faster job completion.

Best Practices: Quick Wins to Start Saving Today

- Start with an audit: Measure current material usage, reject rates, and cycle times to identify baseline improvements.

- Invest in operator training: Focus on spray technique, leveling of coatings, and proper setup procedures.

- Optimize reclaim loops: Ensure overspray recuperation is efficient and easy to operate.

- Standardize settings for common parts: Create reference guides for typical geometries to speed up changeovers.

- Schedule preventive maintenance: Keep guns, hoses, and nozzles in good shape to maintain peak performance.

When to Consider Alternatives: Limitations of Manual Electrostatic Spray Guns

While manual electrostatic spray guns offer many advantages, there are scenarios where alternatives may be more cost-effective:

- Very high-volume production: Automated or robotic systems may deliver superior consistency and throughput for large-scale operations.

- Extremely complex geometries with internal channels: Specialized spray equipment or post-coat inspection may be required.

- Powder with challenging charge properties: Some powder formulations may not respond well to electrostatic charging, necessitating different application approaches.

Summary of Cost-Saving Pathways

- Increase material utilization through improved transfer efficiency.

- Boost labor productivity with consistent technique and faster changeovers.

- Reduce waste via reclaim systems and precise application.

- Control energy and cure costs by avoiding over-application.

- Maintain cost predictability with proactive maintenance and process standards.

Practical Implementation Checklist

- Assess current coating costs and pinpoint waste hotspots.

- Select a manual electrostatic spray gun model within your budget that suits your powder type.

- Train operators on technique, grounding, and safe operation.

- Establish SOPs for setup, run, and cleanup procedures.

- Implement a reclaim loop and monitor overspray losses.

- Schedule regular maintenance and calibration.

Frequently Asked Questions

- How does transfer efficiency impact powder cost?

- What maintenance steps are essential for manual electrostatic spray guns?

- Can manual electrostatic guns handle all types of powder?

- What are the key variables to optimize for cost savings?

- How do I decide between manual electrostatic and automated systems for my operation?

Q1: How does transfer efficiency impact powder cost?

A: Transfer efficiency determines how much powder actually ends up on the part versus wasted as overspray or bounce. Higher transfer efficiency means less material is consumed for the same coating result, reducing material costs and improving yield.

Q2: What maintenance steps are essential for manual electrostatic spray guns?

A: Essential steps include regular nozzle inspection and replacement as needed, checking hoses and seals for leaks, calibrating voltage and current settings, cleaning filters, and ensuring the air supply is clean and regulated.

Q3: Can manual electrostatic guns handle all types of powder?

A: Most common thermoset and some thermoplastic powders are suitable for electrostatic application. However, powder formulations with poor charging characteristics or specialized properties may require alternative application methods or equipment adjustments.

Q4: What are the key variables to optimize for cost savings?

A: Critical variables include powder particle size and flow rate, applied voltage, air flow, gun distance, travel speed, and grounding quality. Optimizing these factors improves deposition efficiency and reduces waste.

Q5: How do I decide between manual electrostatic and automated systems for my operation?

A: Consider production volume, part complexity, required consistency, and budget. Manual systems are cost-effective for smaller runs or frequent changeovers, while automated systems excel in high-volume, high-throughput environments with tight tolerances.

Conclusion

Manual electrostatic spray guns offer a practical route to reduce powder coating costs through improved transfer efficiency, better labor productivity, and reduced waste. By embracing disciplined process control, regular maintenance, and targeted training, facilities can realize meaningful savings while maintaining or enhancing coating quality. For many small to mid-sized shops, these portable, adaptable tools deliver a compelling combination of affordability, flexibility, and performance.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.