Content Menu

● Understanding the basics of powder coating guns

● Key factors to evaluate when choosing

● Throughput and production volume

● Coating quality and consistency

● Substrate complexity and part geometry

● Operator skill, training, and safety

● Equipment cost and total cost of ownership

● Maintenance requirements and downtime

● Flexibility and future expansion

● Design considerations for selecting a system

● Types of powder coating guns to know

● Practical decision framework

● Hybrid and staged approaches

● Safety and compliance considerations

● Maintenance and calibration practices

● Implementation steps for selecting and deploying

● Case scenarios

● Common myths debunked

● Best practices for a successful decision

● Recap: weighing the choice

● Frequently asked questions

Powder coating is a versatile finishing method that delivers durable, high-quality coatings for a wide range of substrates. When selecting the right application equipment, one of the first decisions is whether to use manual or automatic powder coating guns. This choice impacts not only coating quality but also productivity, operator safety, maintenance, and total cost of ownership. This article explains the critical factors to consider, compares the two approaches, and provides practical guidance for different production contexts.

Understanding the basics of powder coating guns

Powder coating guns are designed to electrostatically charge powder particles and propel them toward a grounded workpiece. The charged particles adhere to the surface, creating an even, uniform coating after curing. The gun type influences how powder is applied, how evenly it deposits, how much operator intervention is required, and how the process can be scaled.

Manual powder coating guns are handheld devices operated by a technician. They require direct control over movement, distance, and spray patterns. Automatic powder coating guns are integrated into robotic or fixed automation systems and operate with minimal human intervention, delivering consistent spray patterns and higher throughput.

Key factors to evaluate when choosing

- Throughput and production volume

- Coating quality and consistency

- Substrate complexity and part geometry

- Operator skill, training, and safety

- Equipment cost and total cost of ownership

- Maintenance requirements and downtime

- Flexibility and future expansion

Throughput and production volume

For high-volume production lines with repetitive parts, automatic powder coating guns typically offer superior throughput. They enable consistent spray coverage across numerous parts per hour and reduce cycle times when integrated with conveyors and curing ovens. In contrast, manual guns may suffice for low to medium volumes, smaller batches, or jobs requiring frequent setup changes.

If your facility runs continuous production or batch runs with dozens to hundreds of parts per shift, automatic systems can provide meaningful productivity gains. For small shops or custom projects with irregular workloads, manual guns offer flexibility and lower upfront investment.

Coating quality and consistency

Uniform spray coverage is essential for corrosion resistance, aesthetics, and finish quality. Automatic guns, when paired with well-designed fixtures and precise robotic paths, minimize human variability. They produce reproducible patterns, reduce overspray, and improve edge coverage on complex geometries.

Manual guns rely on the operator's skill and consistency. Experienced technicians can achieve excellent results, but variability between shifts or operators can affect overall finish quality. If your coating requires tight thickness control on intricate geometries, automatic systems often deliver more reliable results.

Substrate complexity and part geometry

Parts with sharp edges, corners, or complex profiles pose challenges for manual spraying due to operator reach and spray patterns. Automatic systems can be programmed to target difficult areas with consistent proximity and angle, improving edge coverage and reducing thin spots.

For very simple geometries or very small components, manual spraying might be sufficient, especially when the parts are in small batches or the line layout favors quick changeovers.

Operator skill, training, and safety

Manual powder coating places the burden of achieving quality on the operator. Training, experience, and steady technique are crucial. Proper PPE, ventilation, and adherence to safety protocols are essential to reduce exposure to powders, dust, and fumes.

Automatic systems reduce direct operator involvement in the spraying stage, enhancing safety and reducing the potential for repetitive strain injuries. However, robotized or automated systems still require maintenance, set-up supervision, and occasional recalibration. They also demand specialized programming and safety interlocks to protect workers.

Equipment cost and total cost of ownership

When comparing costs, consider not only the purchase price but also installation, integration, energy consumption, maintenance, consumables, and depreciation. Automatic powder coating lines generally have higher upfront costs due to robotics, control systems, conveyors, and integration with curing and pretreatment processes. However, the long-term savings from higher throughput, reduced labor, lower material waste, and improved consistency can justify the investment.

Manual systems have lower initial costs and greater flexibility for small shops or variable production. Ongoing labor costs, potential quality variability, and slower throughput should be weighed against the lower capital expenditure.

Maintenance requirements and downtime

Automatic systems demand scheduled preventive maintenance for robots, servo motors, sensors, and control software. Downtime for maintenance should be factored into line efficiency calculations. Manual guns require routine cleaning, nozzle replacement, and calibration, but the maintenance is typically less complex to execute on a day-to-day basis. Part availability for components and spares can influence downtime as well.

Flexibility and future expansion

Consider your anticipated growth, product mix changes, and process upgrades. Automatic systems shine in stable, high-volume scenarios where you can standardize on a set of parts and fixtures. If your business expects frequent changeovers, a modular approach with hybrid configurations—where manual guns work alongside selective automation on critical lines—can offer the best balance.

Design considerations for selecting a system

- Spray gun type and nozzle configuration

- Power supply and corona vs. tribostatic charging

- Containment and ventilation compatibility

- Electrical safety and grounding practices

- Robotic integration and path planning

- Fixture design to support automated paths

- Access for manual touch-ups when needed

Types of powder coating guns to know

- Manual electrostatic spray guns: Portable devices operated by technicians. They are versatile and suitable for small batches or custom runs.

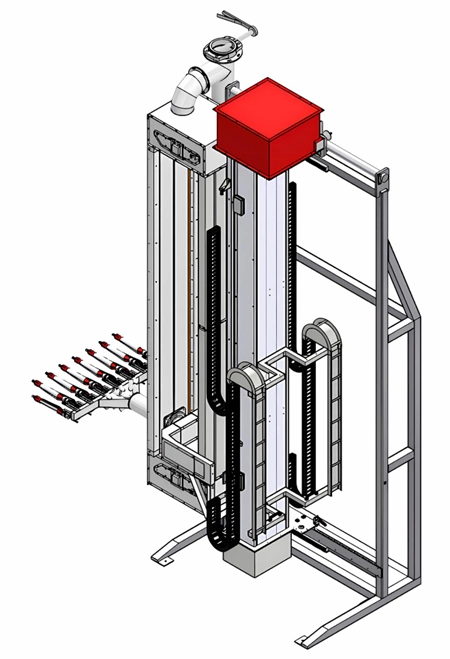

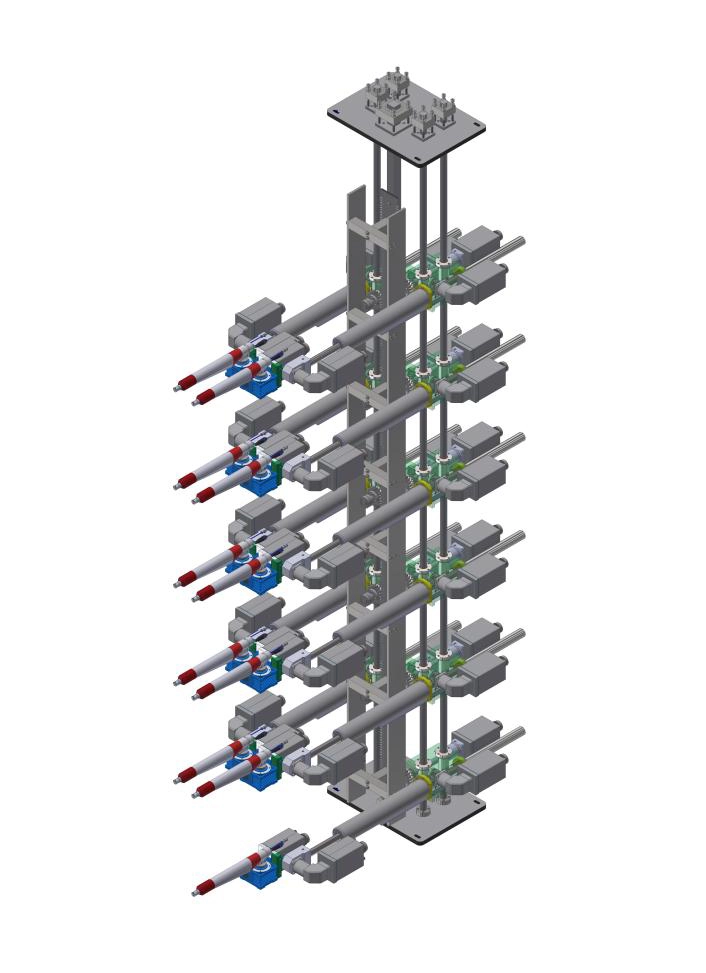

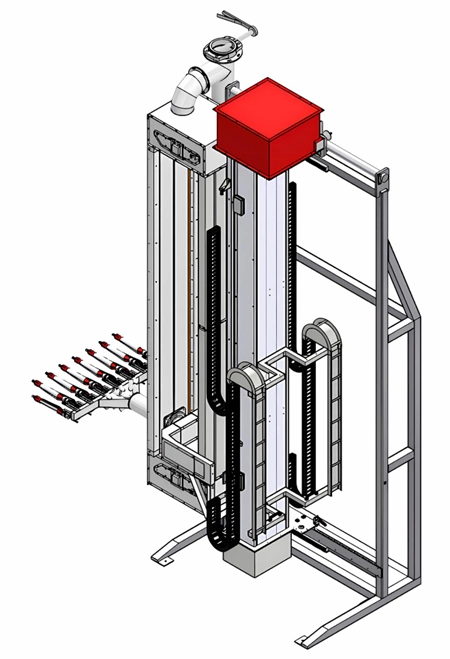

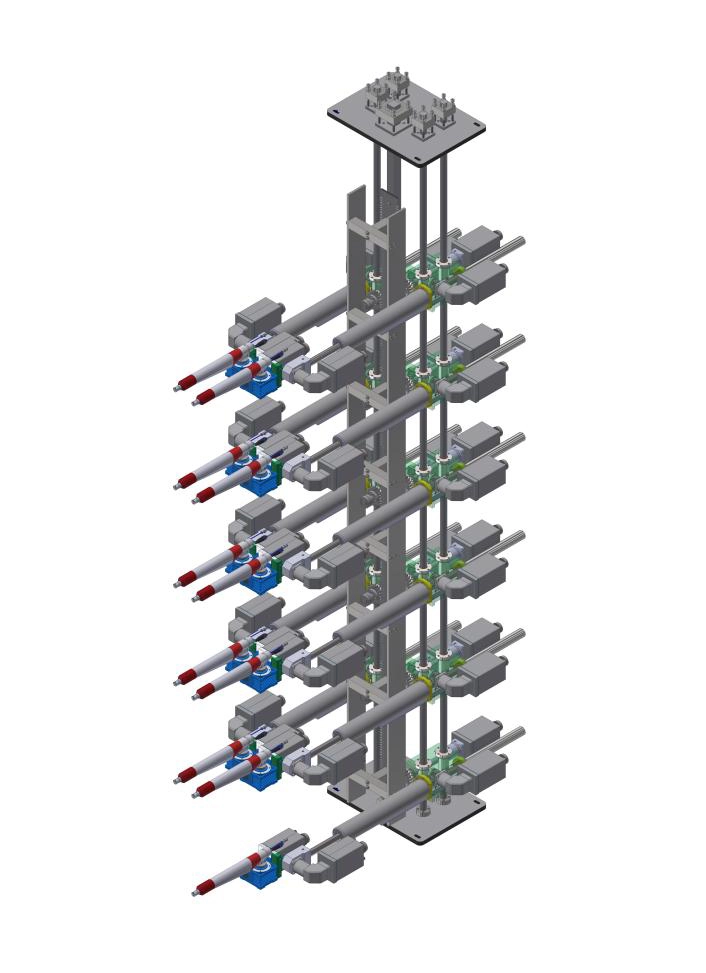

- Automatic spray guns: Fixed or robotic spray systems integrated into production lines. They provide consistent deposition across large volumes.

- Automatic spray guns with multifunction capability: Some systems support both automatic application and manual intervention for flexibility.

Understanding the capabilities and limitations of each gun type helps align the selection with your production goals and budget.

Practical decision framework

1. Define your target throughput per hour and per shift.

2. Assess part geometry and complexity to estimate coverage needs.

3. Evaluate labor availability, skill levels, and safety considerations.

4. Estimate total cost of ownership over a five-year horizon, including maintenance and energy use.

5. Consider future product mix and potential line expansions.

If throughput and consistency are top priorities, and the budget allows, an automatic gun solution integrated with a broader automation strategy is typically the better long-term choice. If you require rapid setup changes, frequent product variation, or lower upfront costs, manual guns may be preferable.

Hybrid and staged approaches

Some facilities adopt a staged modernization path, starting with manual guns and gradually introducing automation on the most demanding stations. This hybrid approach reduces risk, allows learning and calibration, and spreads capital expenditure over time. In practice, you might automate critical stations first and keep manual guns for flexible operations and operator-assisted touch-ups.

Safety and compliance considerations

- Ensure proper ventilation and fume extraction to minimize particle exposure.

- Implement grounded workpieces and proper static control to prevent electrical hazards.

- Provide appropriate personal protective equipment for operators.

- Establish standard operating procedures for maintenance, calibration, and inspection.

- Train staff on best practices for material handling, cleanup, and spill response.

Maintenance and calibration practices

- Schedule regular cleaning of spray tips, nozzles, and housings.

- Check fluid or powder feed consistency and replace consumables as needed.

- Calibrate voltage and current settings to maintain uniform deposition.

- Inspect grounding paths and electrical connections to prevent arcing.

- Record maintenance and performance data to track line efficiency and part quality.

Implementation steps for selecting and deploying

- Conduct a needs assessment with stakeholders from production, maintenance, and safety.

- Run a pilot with a subset of parts to validate coverage and cycle times.

- Compare performance metrics such as coating thickness uniformity, material usage, and downtime.

- Develop a phased implementation plan with milestones and budget allocations.

- Train operators and maintenance staff thoroughly to maximize system uptime.

Case scenarios

- High-volume automotive parts with flat, simple surfaces: Automatic guns on a dedicated line with conveyors typically yield the best consistency and speed.

- Custom bike frames with varying geometries: A hybrid approach allowing manual touch-ups on complex areas can balance quality and flexibility.

- Small metal components for consumer electronics: Manual guns in a compact, adaptable workstation may be cost-effective for low volumes with high variability.

Common myths debunked

- Myth: Automatic systems always produce better finishes. Reality: Finishes depend on the entire process, including fixtures, curing, and pretreatment.

- Myth: Manual spraying is outdated. Reality: Skilled manual spraying remains essential for flexibility and rapid changeovers in many facilities.

- Myth: Automation guarantees zero waste. Reality: Proper process control and calibration are required to minimize overspray and optimize material use.

Best practices for a successful decision

- Start with a clear business case that links throughput, quality, safety, and cost.

- Involve cross-functional teams to capture diverse requirements and constraints.

- Prioritize modularity to enable future upgrades without a full system overhaul.

- Invest in operator training and ongoing process optimization to maximize returns.

Recap: weighing the choice

Manual powder coating guns excel in flexibility, lower upfront costs, and suitability for variable, small-batch work. Automatic powder coating guns offer higher throughput, more consistent finishes, and lower labor dependence for large-scale, standardized production. The optimal choice depends on your production volume, part geometry, cost constraints, and long-term strategic plans.

Frequently asked questions

- What are the main advantages of manual powder coating guns?

- How does automation impact coating thickness control?

- What kind of maintenance does an automatic powder coating line require?

- Can a facility operate with both manual and automatic spraying?

- How do pretreatment and curing processes influence the final finish?

Would you like this article tailored to a specific industry (for example, automotive, HVAC, or consumer electronics) or adjusted for a particular production scale and budget?

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.