Content Menu

● Understanding Coating Purity

>> What is Coating Purity?

● Introduction to Powder Sieving in Coating Processes

● What is a Swinger Powder Sieve System?

>> Basic Design and Operation

>> Components of the System

● How Swinger Powder Sieve Systems Help Maintain Coating Purity

>> Efficient Separation and Classification

>> Reduced Particle Degradation

>> Prevention of Cross-Contamination

>> Adaptability to Various Powder Types

● Advantages Over Other Sieving Technologies

>> Compared to Vibrating Sieves

>> Compared to Rotating or Tumbler Sieves

● Applications of Swinger Powder Sieve Systems in Coating Industries

>> Pharmaceutical Coatings

>> Paints and Pigments

>> Powder Coatings

>> Food or Cosmetic Powders for Coatings

● Installation and Maintenance Considerations

>> Proper Installation

>> Routine Maintenance Practices

>> Troubleshooting Tips

● Future Trends in Swinger Powder Sieving Technology

>> Automation and Process Control

>> Advanced Materials and Mesh Design

>> Sustainability and Energy Efficiency

● Conclusion

● Related Questions and Answers

Maintaining coating purity is paramount in various industries such as pharmaceuticals, food processing, chemicals, and coatings manufacturing. The quality and consistency of coatings greatly affect product performance, safety, and compliance with regulations. One critical technology that ensures the purity and quality of powdered materials used in coatings is the swinger powder sieve system. This article delves into the role of swinger powder sieve systems in maintaining coating purity, exploring their design, functions, benefits, and applications.

Understanding Coating Purity

What is Coating Purity?

Coating purity refers to the quality standard that ensures a coating material is free from contaminants, oversized particles, clumps, and unwanted residues. High purity in coatings leads to uniform application, improved durability, and enhanced aesthetic and functional properties of the final product.

Purity becomes vital when dealing with powders used as raw materials or additives in coatings, such as pigments, fillers, binders, and functional powders. Contaminants or impurities can alter the chemical and physical properties of coatings, affecting adhesion, color, gloss, and resistance characteristics.

***

Introduction to Powder Sieving in Coating Processes

Powder sieving is a separation process used to classify particles based on size and to remove contaminants and oversized agglomerates. It ensures that only particles within a specified size range are used, thereby maintaining the purity and quality of the powder prior to its use in coatings.

Traditional sieving methods may not be sufficient for powders with sensitive properties or for applications demanding ultra-fine classification. This is where swinger powder sieve systems come into play, offering advanced, efficient, and gentle powder screening capabilities.

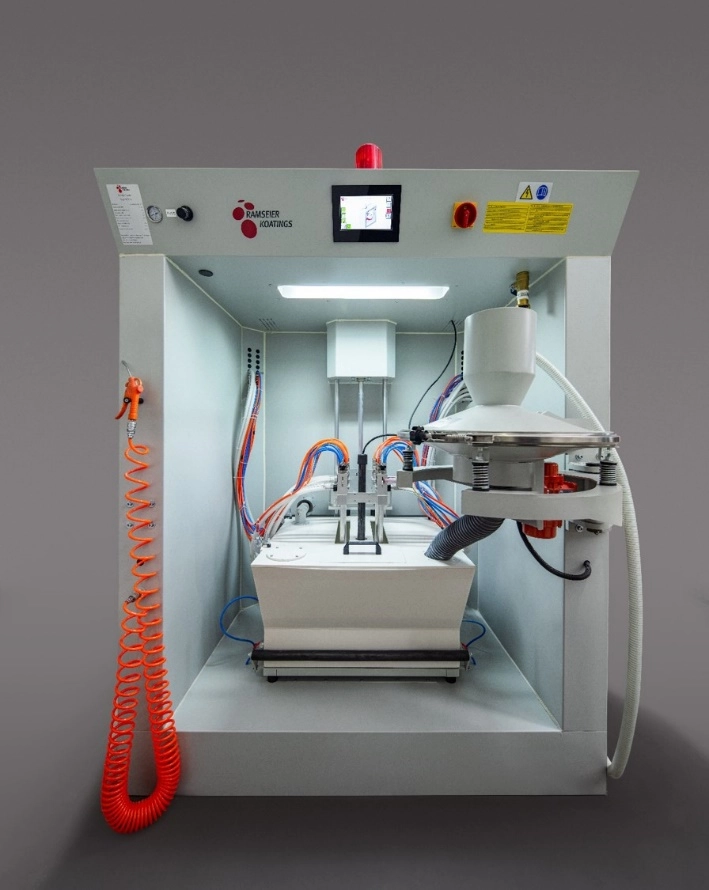

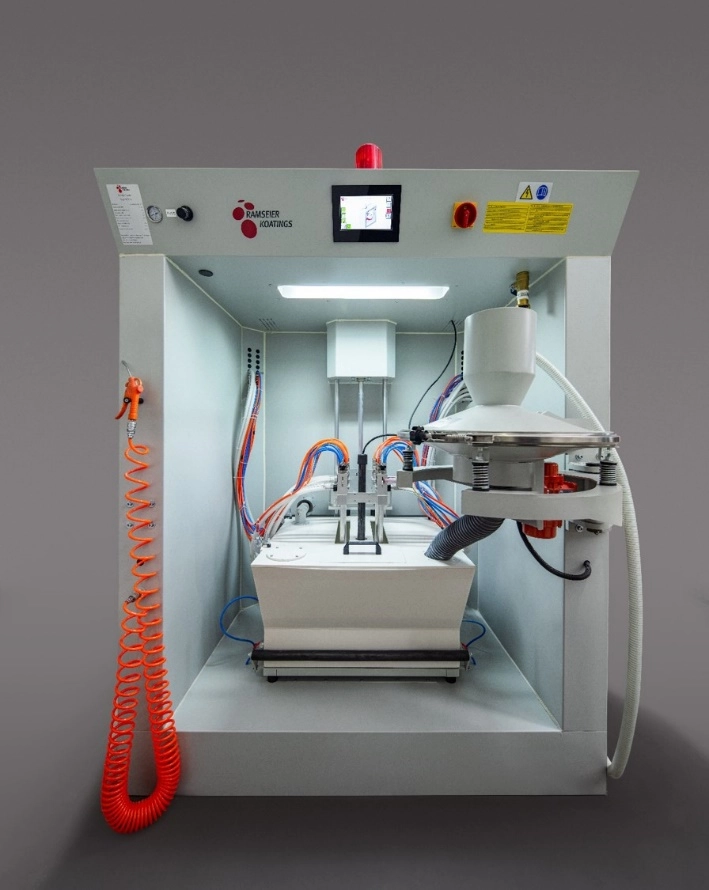

What is a Swinger Powder Sieve System?

Basic Design and Operation

A swinger powder sieve system is a sieve or screen equipped with a swinging or oscillating mechanism that moves the sieve mesh in a controlled and repetitive manner. This swinging motion allows the powder particles to pass through the sieve openings efficiently while separating oversized particles and contaminants.

Unlike vibrating sieves that use vertical or horizontal vibrations, swinger sifters rely on a swinging action which tends to be gentler on sensitive powder particles. This reduces particle breakage and preserves the quality of the material.

Components of the System

- Screen Mesh: The heart of the sieving system, available in various mesh sizes depending on the required particle size distribution.

- Swinging Mechanism: Typically driven by an electromagnetic or mechanical motor, enabling controlled oscillations.

- Frame and Housing: Designed to contain the material and capture oversize or contaminant particles separately.

- Discharge Outlets: For screened, oversized, and waste materials.

How Swinger Powder Sieve Systems Help Maintain Coating Purity

Efficient Separation and Classification

The swinging motion enables powders to spread evenly across the mesh surface, maximizing screening efficiency and throughput. This ensures finer separation of impurities and oversized granules which could otherwise compromise coating quality.

Reduced Particle Degradation

Because the swinger motion is gentler than high-frequency vibrations, delicate powders retain their original properties without particle fracturing or alteration. This is particularly important for coatings that rely on powders with precise particle morphology for uniform appearance and performance.

Prevention of Cross-Contamination

Modern swinger sieve systems are designed with enclosed housings and dust-tight seals, preventing airborne contamination and protecting the purity of the powder during screening.

Adaptability to Various Powder Types

Swinger sieves can handle a wide range of materials, from fine pigments to coarser functional powders, with adjustable swing frequencies and sieve mesh sizes, ensuring optimized processing for each specific coating ingredient.

Advantages Over Other Sieving Technologies

Compared to Vibrating Sieves

- Gentler on Powders: Less particle damage.

- Lower Noise Levels: Swinging mechanisms produce less noise compared to high-frequency vibration.

- Energy Efficiency: Typically consume less power.

Compared to Rotating or Tumbler Sieves

- More Uniform Screening: Swinging action provides consistent particle movement across the sieve.

- Simpler Maintenance: Fewer moving parts result in easier upkeep.

Applications of Swinger Powder Sieve Systems in Coating Industries

Pharmaceutical Coatings

Pharmaceutical coatings require extremely high purity to prevent contamination that can affect drug efficacy and safety. Swinger powder sieves are employed to screen powdered excipients such as film-forming polymers and plasticizers.

Paints and Pigments

In paint manufacturing, powder pigments and additives must be uniformly sized for consistent color and texture. Swinger sieve systems ensure that agglomerates and foreign particles are removed from powdered pigments.

Powder Coatings

Powder coatings demand precise particle size control for proper flow and curing behavior. Swinger sieves help eliminate lumps and contamination, ensuring smooth application and finish.

Food or Cosmetic Powders for Coatings

Where edible or cosmetic coatings are produced, swinger sieve systems help in maintaining hygienic conditions and purity by removing contaminants from powdered ingredients.

Installation and Maintenance Considerations

Proper Installation

Installing swinger powder sieve systems requires attention to foundation stability, alignment with feeding and discharge systems, and integration with dust extraction units to ensure optimum performance.

Routine Maintenance Practices

- Screen Mesh Cleaning: Regular cleaning to prevent clogging.

- Lubrication of Moving Parts: To maintain smooth swinging action.

- Inspection for Wear and Damage: Timely replacement of worn parts.

- Sealing Checks: To prevent dust leakage and contamination.

Troubleshooting Tips

- Address inconsistent screening by verifying swing amplitude and frequency settings.

- Inspect for blockages that reduce screening efficiency.

- Ensure feed rate matches the screening capacity.

Future Trends in Swinger Powder Sieving Technology

Automation and Process Control

Integration of sensors and automated adjustments allows real-time monitoring and optimization of sieve performance, reducing human error and increasing consistency.

Advanced Materials and Mesh Design

Development of ultra-fine mesh materials with enhanced durability and anti-clogging properties improves screening quality for very fine powders.

Sustainability and Energy Efficiency

Enhancements in motor efficiency and system design reduce energy consumption and environmental impact of screening processes.

Conclusion

The swinger powder sieve system is an essential technology in the maintenance of coating purity across diverse industries. Its gentle yet efficient screening action ensures particle size uniformity, removal of contaminants, and preservation of powder integrity. By securing the quality of powdered raw materials, swinger sieve systems contribute to the production of high-quality coatings that meet exacting standards. As technological advancements continue, swinger sieve systems will remain pivotal in facilitating innovation and quality assurance in coating manufacturing.

Related Questions and Answers

Q1: What types of powders are best suited for swinger powder sieve systems?

A1: Powders that require gentle handling or have sensitive particle structures, such as pharmaceutical excipients, pigments, and fine chemical powders, benefit most from swinger powder sieve systems.

Q2: How is the mesh size selected for a swinger powder sieve system?

A2: Mesh size is selected based on the desired particle size distribution for the final powder product and the removal requirements for impurities and oversized particles in the coating process.

Q3: Can swinger powder sieve systems handle wet or sticky powders?

A3: While primarily designed for dry powders, some swinger sieve systems can be adapted or equipped with anti-clogging features to handle slightly moist or sticky powders.

Q4: What maintenance is essential to keep swinger powder sieves operating effectively?

A4: Regular cleaning of mesh screens, lubrication of mechanical parts, inspection for wear or damage, and ensuring seals are intact to prevent contamination are critical maintenance steps.

Q5: How does swinging motion improve screening efficiency compared to traditional vibration?

A5: The swinging motion promotes even spreading of material across the screen surface, reduces particle clustering, and gently moves particles through the mesh, enhancing throughput and reducing particle damage.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.