Content Menu

● Table of Contents

● Introduction

● Understanding Powder Sieves

>> Types of Powder Sieves

>> Common Uses in Industry

● Why Maintenance is Crucial

● Essentials for Cleaning and Maintenance

● Step-by-Step Cleaning Guide

>> 1. Preparation

>> 2. Disassembly

>> 3. Primary Cleaning

>> 4. Deep Cleaning Techniques

>> 5. Drying and Inspection

>> 6. Reassembly

● Maintaining Your Powder Sieve

>> Daily Maintenance Routines

>> Periodic Deep Maintenance

>> Troubleshooting Common Issues

● Best Practices for Longevity and Performance

● Tips for Safe Sieve Handling

● Frequently Asked Questions

>> 1. How often should I clean my powder sieve?

>> 2. Can I use any cleaning agent for my sieve?

>> 3. My sieve mesh seems clogged—how do I restore it?

>> 4. What should I do if my sieve develops a hole or tear?

>> 5. How do I prevent cross-contamination between different powders?

Keeping your powder sieve in peak condition is crucial for accurate, consistent results in any powder processing operation. Whether you work in pharmaceuticals, food production, metallurgy, or chemical industries, maintaining your sieve not only prolongs its lifespan but also ensures the quality and safety of your product. This comprehensive guide explores step-by-step processes, common challenges, specialized advice, and much more to help you achieve optimal powder sieving results.

Table of Contents

- Introduction

- Understanding Powder Sieves

- Types of Powder Sieves

- Common Uses in Industry

- Why Maintenance is Crucial

- Essentials for Cleaning and Maintenance

- Step-by-Step Cleaning Guide

- Preparation

- Disassembly

- Primary Cleaning

- Deep Cleaning Techniques

- Drying and Inspection

- Reassembly

- Maintaining Your Powder Sieve

- Daily Maintenance Routines

- Periodic Deep Maintenance

- Troubleshooting Common Issues

- Best Practices for Longevity and Performance

- Tips for Safe Sieve Handling

- Frequently Asked Questions

- Word Count

- Article Summary

Introduction

Powder sieves are vital in separating, classifying, and de-lumping powdered materials. Over time, even the most robust sieves accumulate residues or experience wear that diminishes their accuracy and reliability. Regular cleaning and maintenance are the antidotes—ensuring products meet strict quality standards and equipment downtime or costly repairs are kept at bay. This article guides beginners and experts alike on how to achieve the best possible results from your powder sieve through proper maintenance and cleaning.

Understanding Powder Sieves

Types of Powder Sieves

- Manual Sieves: Operated by hand, ideal for smaller batches and simple processes.

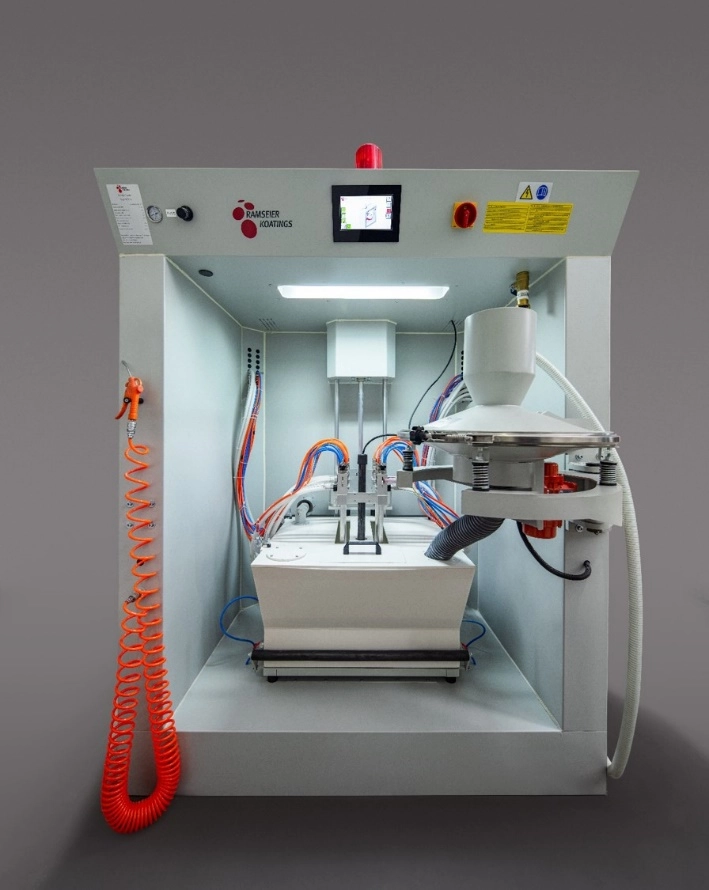

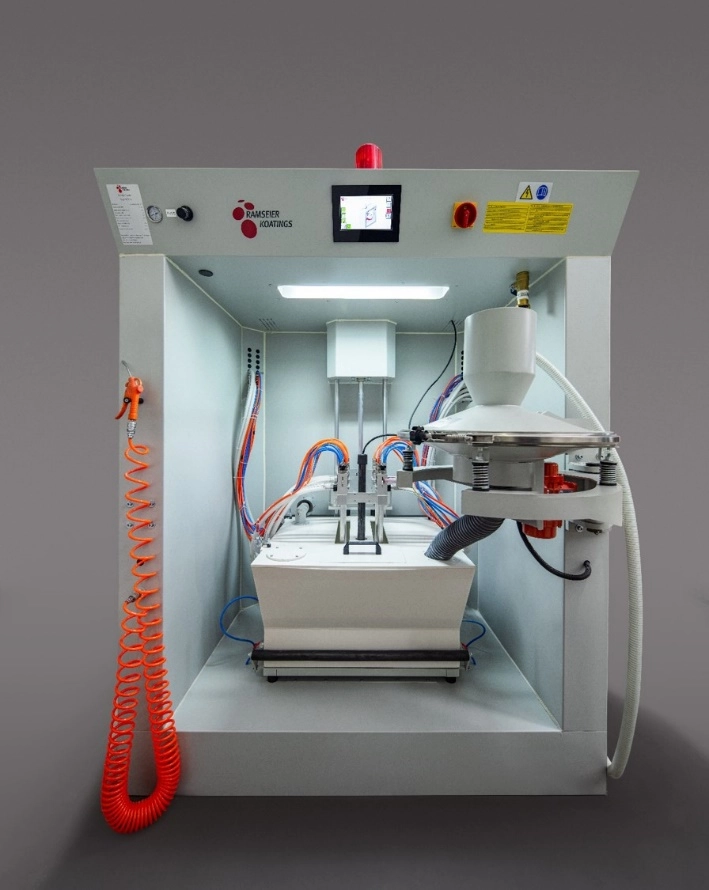

- Mechanical Sieves: Utilize vibration, rotation, or tapping via motors to increase throughput and consistency.

- Ultrasonic Sieves: Use high-frequency vibrations for ultra-fine powders and challenging separations.

- Multi-Deck Sieves: Contain several stacked screens to separate powders by multiple size grades in one operation.

Common Uses in Industry

- Pharmaceuticals: Ensuring uniform particle size for tablet production.

- Food and Beverage: Filtering spices, flour, or powdered additives for purity.

- Chemical Manufacturing: Classifying or removing contaminants from powdered chemicals.

- Metallurgy: Separating metal powders for additive manufacturing.

Why Maintenance is Crucial

Proper maintenance of powder sieves offers several essential benefits:

- Consistent Product Quality: Clean sieves guarantee accurate separation and prevent cross-contamination.

- Regulatory Compliance: Many industries mandate regular cleaning and maintenance for hygiene and safety.

- Longevity of Equipment: Well-maintained sieves last longer, reducing costs from frequent replacements.

- Reduced Downtime: Proactive maintenance prevents unexpected breakdowns and process interruptions.

- Operator Safety: Proper handling and cleaning reduce risks associated with contaminated or damaged sieves.

Essentials for Cleaning and Maintenance

Before proceeding with cleaning or maintenance, ensure you have the following:

- Personal Protective Equipment (PPE): Gloves, safety glasses, and masks.

- Appropriate Cleaning Tools: Brushes with soft and hard bristles, non-metallic scrapers, soft cloths.

- Approved Cleaning Agents: Non-corrosive detergents suited to the sieve's material.

- Compressed Air or Vacuum Cleaner: For removing fine powder particles.

- Repair Tools: Wrenches, screwdrivers, or other tools for disassembly and reassembly.

Step-by-Step Cleaning Guide

1. Preparation

- Review Manuals: Always consult the manufacturer's guidelines for specific cleaning instructions.

- Ensure Safety: Power down and unplug automated sieves. Use PPE to avoid skin or eye contact with powders or cleaning solutions.

- Work Area: Clean, well-ventilated area with sufficient space to lay out all parts.

2. Disassembly

- Careful Removal: Gently disentangle all detachable parts, such as frames, retaining rings, gaskets, and screens.

- Documentation: Label and photograph parts to expedite correct reassembly, particularly with multi-deck or custom sieves.

3. Primary Cleaning

- Dry Brushing: Use a soft dry brush to loosen and sweep away loose powder from all surfaces.

- Vacuuming: A vacuum cleaner with a HEPA filter captures residual fine particles.

- Initial Washing: For metal sieves, rinse with warm water and use a gentle detergent to remove residues. Take care not to damage mesh openings.

4. Deep Cleaning Techniques

- Soaking: For stubborn or caked-on residues, soak components in a mild cleaning solution (never too hot, as this may warp or damage the frame and mesh).

- Ultrasonic Baths: For laboratory-grade sieves, an ultrasonic cleaner dislodges fine particles, especially from mesh apertures. Limit exposure to manufacturer recommendations so as not to weaken the mesh.

- Manual Scrubbing: Use soft-bristle brushes in circular motions, avoiding excessive force. Hard bristles or wire brushes risk tearing or distorting the mesh.

- Avoid Abrasives: Never use steel wool or abrasive powders unless the manufacturer specifically approves their use for your sieve's mesh material.

5. Drying and Inspection

- Air Drying: Pat down with lint-free cloth, then allow components to air dry completely. Compressed air helps remove water from fine pores.

- Inspection: Check for holes, tears, or deformation. Pay special attention to mesh integrity, as even tiny flaws can compromise results.

- Functional Testing: If possible, conduct a quick test with a sample powder to ensure performance before full reassembly.

6. Reassembly

- Careful Installation: Reassemble components exactly as disassembled, referring to your photos or notes.

- Alignment: Ensure screens are taut and properly seated to prevent vibration or leakage during use.

- Fastening: Secure all bolts, clips, and clamps firmly, but do not overtighten, as this can distort components.

Maintaining Your Powder Sieve

Daily Maintenance Routines

- Quick Wipe-Downs: After each batch, remove residual powders with a brush or air jet before buildup occurs.

- Visual Inspection: Check for visible clogging, mesh distortion, or powder accumulation.

- Record Keeping: Maintain a log noting cleaning times, observed wear, and any incidents of damage.

Periodic Deep Maintenance

- Scheduled Cleaning: In addition to daily routines, conduct thorough cleanings weekly or monthly, depending on workload and powder type.

- Component Checks: Periodically inspect seals, gaskets, and screens for wear. Replace if necessary.

- Calibration: Some sieves, especially mechanical or digital types, require periodic calibration to ensure performance.

Troubleshooting Common Issues

- Clogged Mesh: Soak and use ultrasonic cleaning. Consider using anti-blinding devices or softer brushes.

- Powder Leakage: Check seals and frames for wear. Replace or repair as required.

- Unusual Vibration or Noise: Inspect for debris lodged in moving parts or loose fastenings.

- Reduced Throughput: Ensure mesh is clean and free from blockages. Check for mesh tension or misalignment issues.

Best Practices for Longevity and Performance

- Routine Checks: Regularly inspect mesh, gaskets, and structural frames for signs of fatigue or damage.

- Proper Storage: Store sieves in a clean, dry place to prevent corrosion or contamination. Use protective covers or bags.

- Rotation of Use: For operations with multiple sieves, rotate their use to ensure even wear and longer service life.

- Proper Handling: Always handle by the frame, never by the mesh. Avoid stacking heavy items atop sieves to prevent warping.

Tips for Safe Sieve Handling

- Use Both Hands: Lift and carry using both hands to distribute weight evenly and minimize accidental drops.

- Clean Spills Immediately: Any spilled powder should be cleaned up promptly to avoid transfer and contamination.

- Dedicated Cleaning Tools: Use tools reserved solely for sieve maintenance to avoid introducing contaminants.

- Follow Manufacturer Recommendations: Every sieve type and brand may have specific care requirements.

- Training: Ensure all operators are thoroughly trained in proper sieve use and maintenance.

Frequently Asked Questions

1. How often should I clean my powder sieve?

Cleaning frequency depends on usage volume and powder type. For food and pharmaceutical applications, cleaning after every batch is recommended. In less critical applications, daily cleaning may suffice.

2. Can I use any cleaning agent for my sieve?

Only use cleaning agents that the manufacturer approves for your specific mesh and frame materials. Harsh chemicals or solvents can erode or warp screens, leading to performance issues.

3. My sieve mesh seems clogged—how do I restore it?

Soak in an approved cleaning solution, then use a soft-bristle brush or ultrasonic cleaner. Avoid excessive scrubbing or metal brushes, which can damage the mesh.

4. What should I do if my sieve develops a hole or tear?

Cease use immediately. Replace the mesh or entire sieve, as repaired holes typically do not restore original performance and may cause contamination.

5. How do I prevent cross-contamination between different powders?

Thoroughly clean and dry all sieve components between batches. Maintain dedicated tools for cleaning. Consider using separate sieves for allergenic or sensitive powders when feasible.

Proper maintenance and cleaning of your powder sieve are essential for the production of high-quality, contaminant-free powders in industrial environments. By adopting regular inspection routines, using appropriate cleaning methods, and addressing common problems promptly, you guarantee product safety, equipment longevity, and smooth workflow. Consistent care not only meets regulatory demands but also protects your investment in the long run.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.