Content Menu

● What Are Powder Sieves and Why Are They Important?

>> The Role of Particle Size in Powder Coatings

>> Types of Powder Sieves

● How Powder Sieves Improve Coating Efficiency

>> Removal of Oversize Particles and Agglomerates

>> Ensuring Consistent Powder Quality

>> Enhancing Powder Recovery and Reuse

>> Improving Flow and Process Throughput

>> Preventing Equipment Wear and Maintenance

● How Powder Sieves Reduce Waste

>> Minimizing Overspray Waste Through Powder Recovery Systems

>> Reducing Scrap from Defective Coatings

>> Lowering Raw Material Consumption

>> Less Energy and Resource Use from Rework

● Implementing Powder Sieves in Coating Processes

>> Pre-Application Sieving

>> In-Line Sieving Before Spray Guns

>> Sieving in Powder Recovery Systems

>> Choosing and Optimizing Sieving Equipment

● Benefits of Using Powder Sieves for Coating Operations

● Challenges and Considerations

● Related Questions and Answers

Powder coating is a widely used finishing process in industries such as automotive, electrical appliances, and consumer goods. The quality, durability, and environmental friendliness of powder coatings have driven their popularity. However, achieving high coating efficiency and minimizing waste requires careful control of the powder's properties, especially particle size and uniformity. Powder sieves play a crucial role in this process. This article explores how powder sieves enhance coating efficiency, improve product quality, and substantially reduce waste.

What Are Powder Sieves and Why Are They Important?

Powder sieves are screening devices designed to separate powder particles based on size. Their primary function is to remove oversized lumps, agglomerates, and foreign contaminants from powder coatings before application. The sieving process ensures that only powders within a desired particle size distribution proceed to the spraying phase.

The Role of Particle Size in Powder Coatings

Particle size uniformity affects how powder coatings flow, adhere, and cure on surfaces. Overly large particles or agglomerates can clog spraying equipment or cause uneven coating surfaces. Fine particles, if not controlled, may result in poor coverage or inconsistent thickness.

Sieving guarantees a consistent particle size range, which smooths powder flow through equipment and produces even coverage and superior finish on coated parts. It also enhances the durability of the coating, as uniform particles melt and cure evenly without weak spots.

Types of Powder Sieves

Several types of sieves are employed in powder coating processes, including:

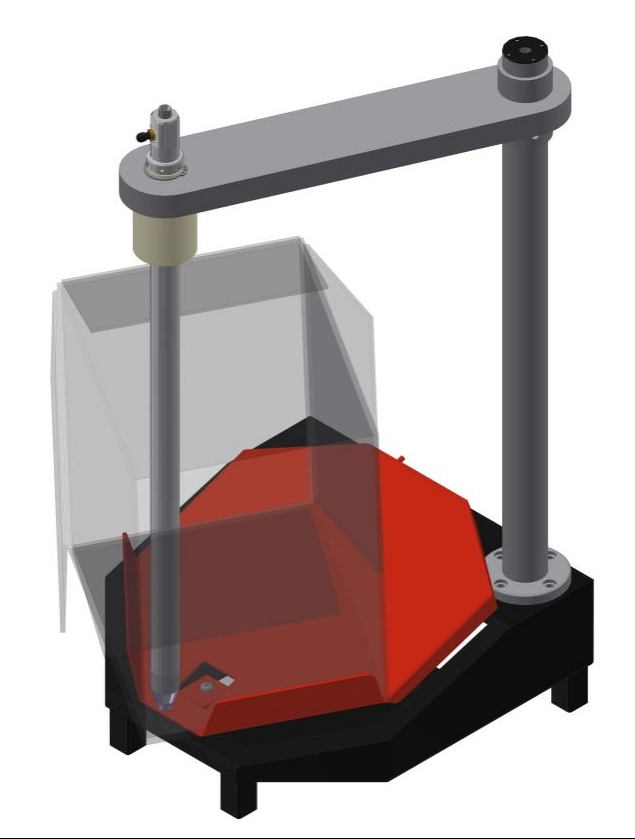

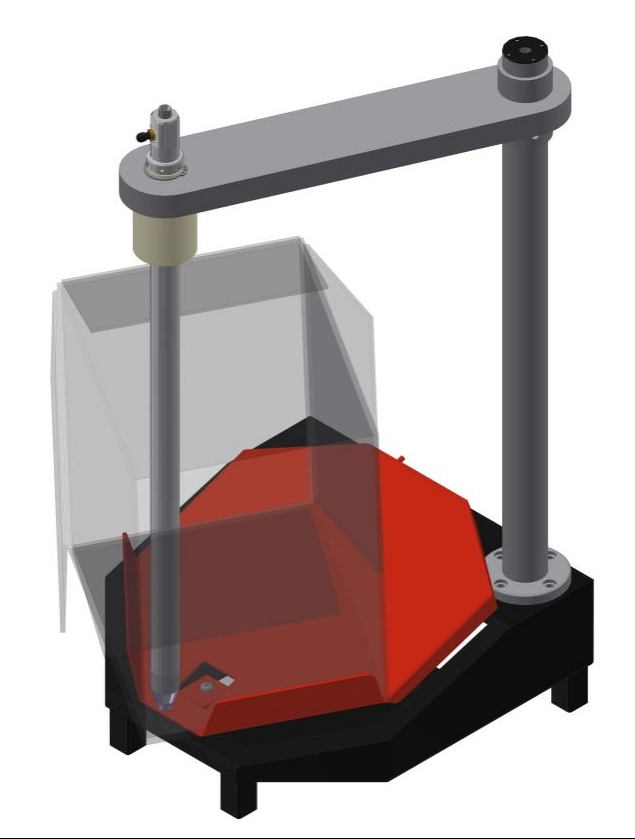

- Vibratory Sieves: Use mechanical vibrations to pass powder through mesh screens, separating appropriately sized particles.

- Cyclone Screeners: Utilize centrifugal force to break up agglomerates and sieve the powder simultaneously, commonly used for continuous production lines.

- High-Energy Sieves (e.g., Hi-Sifter): Provide fine particle screening with high throughput and reduced mesh blinding.

The choice depends on volume requirements, powder characteristics, and quality specifications.

How Powder Sieves Improve Coating Efficiency

Removal of Oversize Particles and Agglomerates

Oversized particles and agglomerates cause frequent blockages in spray guns, leading to costly downtime. By sieving powders before application, problematic particles are removed, allowing smooth powder flow and uninterrupted spraying.

For example, cyclone screeners disintegrate agglomerates actively before powder enters the coating system. This results in uniform application and fewer equipment issues.

Ensuring Consistent Powder Quality

Constant powder quality is vital to maintaining a reproducible, high-quality coating finish. Sieves help maintain that quality by rejecting undersized and oversized particles that might degrade finish appearance or adhesion. This consistency improves first-pass yield rates, reducing the need for costly rework or scrap.

Enhancing Powder Recovery and Reuse

In spray coating, overspray powder falls off parts and is typically collected for recycling. This powder often contains lumps and impurities accumulated during spraying. Incorporating sieving in the recovery system enables the removal of these unwanted particles, allowing reclaimed powder to be reused without degrading coating quality.

This closed-loop reuse cuts raw material costs significantly while lowering waste disposal needs.

Improving Flow and Process Throughput

Uniform powder particles flow more easily through feeding and spraying equipment, enabling faster processing speeds without sacrificing quality. The reduction in clogs and equipment stops fosters higher throughput and production efficiency.

Preventing Equipment Wear and Maintenance

Sieving controls powder purity, reducing abrasive particles that cause premature wear inside pumps, feeders, and spray guns. This extends equipment life and decreases maintenance frequency and costs.

How Powder Sieves Reduce Waste

Minimizing Overspray Waste Through Powder Recovery Systems

Powder coating overspray is a substantial source of material waste. Modern coating lines often integrate sieving with recovery systems. Overspray powder is collected, sieved to remove agglomerates and impurities, then returned to the spray system in a clean, consistent state.

This reuse loop reduces powder consumption and landfill waste drastically.

Reducing Scrap from Defective Coatings

Improved powder uniformity leads to fewer defects like uneven thickness, poor adhesion, or unsightly finishes that require rejection or repainting. By minimizing these quality issues, sieving lowers the volume of coated parts scrapped or reprocessed.

Lowering Raw Material Consumption

With fewer defects and less overspray waste, companies need less raw powder to achieve target production volumes, directly cutting material costs and environmental impact.

Less Energy and Resource Use from Rework

Reducing coating defects also lowers the need for energy-intensive rework processes such as stripping, recoating, or baking, further saving resources.

Implementing Powder Sieves in Coating Processes

Pre-Application Sieving

Sieving raw powder materials before entering the coating line removes lumps formed during storage or transport, ensuring a clean, optimal feedstock into the spraying equipment.

In-Line Sieving Before Spray Guns

Some systems include sieves directly before the spray guns to catch any newly formed agglomerates or contaminants in the material flow, protecting the equipment and final coating quality.

Sieving in Powder Recovery Systems

As part of overspray collection and recycling, sieving stages clean recovered powder before feeding it back into the hopper or spray guns.

Choosing and Optimizing Sieving Equipment

Factors for selecting powder sieves include:

- Particle size specifications

- Powder flow characteristics

- Production throughput requirements

- Floor space and integration needs

- Maintenance and downtime minimization

Technologies like high-energy vibratory sieves or cyclone screeners have been favored in high-demand environments for their reliability and efficiency.

Benefits of Using Powder Sieves for Coating Operations

- Consistent high-quality coatings: Uniform particle size leads to smooth, even finishes.

- Improved spray gun performance: Reduced clogging and stoppages.

- Waste reduction: Minimizes overspray and defective coatings.

- Cost savings: Less raw powder used and reclaimed powder reused.

- Increased productivity: Higher throughput and less downtime.

- Environmental sustainability: Less powder waste sent to landfills.

Challenges and Considerations

- Initial Investment: Sieving systems, especially advanced models, require capital expenditure.

- Proper Maintenance: Screens can clog over time and need periodic cleaning or replacement.

- Powder Characteristics: Some powders are prone to static, moisture, or clumping, requiring tailored sieving solutions.

- Integration: Equipment must be well integrated with existing coating lines to maximize benefits.

Related Questions and Answers

Q1: Why is particle size control critical in powder coatings?

A1: Particle size affects powder flow, spray gun performance, coating smoothness, adhesion, and curing. Uniform particles ensure quality and efficiency.

Q2: Can sieved powder coatings be reused after overspray collection?

A2: Yes, sieving removes impurities and agglomerates from recovered powder, enabling its reuse without compromising coating quality, reducing waste and cost.

Q3: What types of powder sieves are commonly used in coating processes?

A3: Vibratory sieves, cyclone screeners, and high-energy sieves such as Hi-Sifters are typical choices depending on powder properties and production needs.

Q4: How does sieving reduce equipment maintenance in powder coating systems?

A4: By preventing agglomerates and contaminants from entering spray guns and pumps, sieving reduces abrasive wear and blockages, extending equipment life.

Q5: What are the environmental benefits of implementing powder sieves?

A5: Powder sieves reduce raw material waste, minimize overspray disposal, and lower energy consumption from rework, contributing to greener manufacturing.

[1] https://www.farleygreene.com/blog/sieving-for-dry-powder-coatings/

[2] https://news.qq.com/rain/a/20250115A04XRT00

[3] https://azoasia.com/applications/powder-coating-screening-recovery/index.html

[4] https://patents.google.com/patent/CN101218068B

[5] https://elcanindustries.com/blog_posts/powder-coating-sieves-what-are-the-pros-and-cons-heres-what-you-need-to-know/

[6] https://patents.google.com/patent/CN102355941A/zh

[7] https://pflaumer.com/the-benefits-and-importance-of-using-molecular-sieve-paste-in-high-performance-coatings/

[8] https://patents.google.com/patent/CN118268248A/zh

[9] https://www.ramseierkoatings.com/why-powder-sieves-are-essential-for-consistent-powder-coating-performance.html

[10] https://patents.google.com/patent/CN108697955B/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.