Content Menu

● Understanding Powder Sieving: Manual vs Automatic Models

>> What is Powder Sieving?

>> How Manual Powder Sieving Works

>> How Automatic Powder Sieving Operates

● Efficiency and Throughput: Speed Differences

● Accuracy and Consistency in Sieving

>> Manual Sieving: Risks of Human Error

>> Automatic Sieving: Precision and Reproducibility

● Labor and Cost Considerations

>> Labor Intensity of Manual Methods

>> Reduced Labor Costs with Automation

● Maintenance and Durability

>> Maintenance of Manual Sieves

>> Maintenance Challenges of Automatic Machines

● Cost of Equipment: Initial Investment vs Long-Term Value

● Operational Scenarios: Which Model Fits Your Needs?

● Advantages and Disadvantages Summary

● Emerging Trends in Automatic Powder Sieving Technology

● Frequently Asked Questions (FAQs)

Powder sieving is an essential process in various industries, from pharmaceuticals to food production and manufacturing, where powder quality and particle size distribution critically affect the performance and consistency of final products. Choosing between automatic and manual powder sieves is a key decision that influences production efficiency, accuracy, labor costs, maintenance, and overall operational effectiveness. This article explores in-depth the differences between automatic powder sieves and manual models, highlighting their working mechanisms, advantages, drawbacks, and operational considerations to guide businesses in selecting the most suitable equipment for their needs.

Understanding Powder Sieving: Manual vs Automatic Models

What is Powder Sieving?

Powder sieving is the process of separating powders into different particle size fractions by passing them through mesh screens. It removes larger lumps, impurities, and ensures consistent particle size distribution, which is vital for product quality control and uniformity. Sieving can be performed manually or with automated machinery.

How Manual Powder Sieving Works

Manual sieving relies entirely on human effort. Operators spread the powder on a screen and physically agitate it—often by shaking, tapping, or brushing—so that smaller particles pass through the mesh. This hands-on process demands constant attention to maintain even distribution and avoid clumping. Its simplicity means minimal equipment requirements, usually just a sieve frame, screen, and some hand tools.

How Automatic Powder Sieving Operates

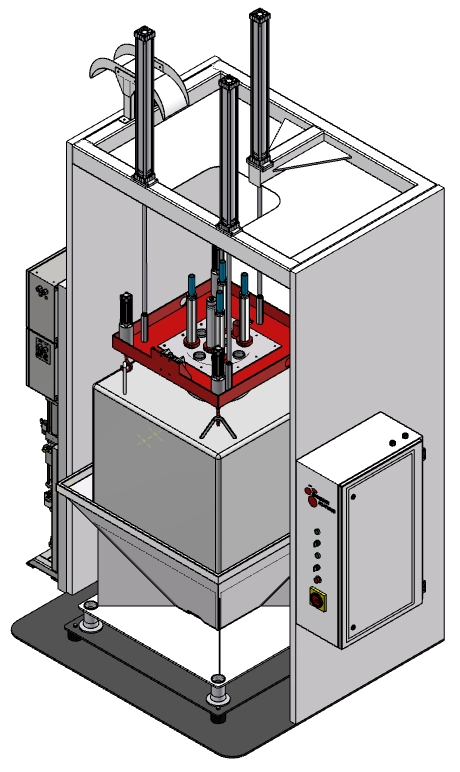

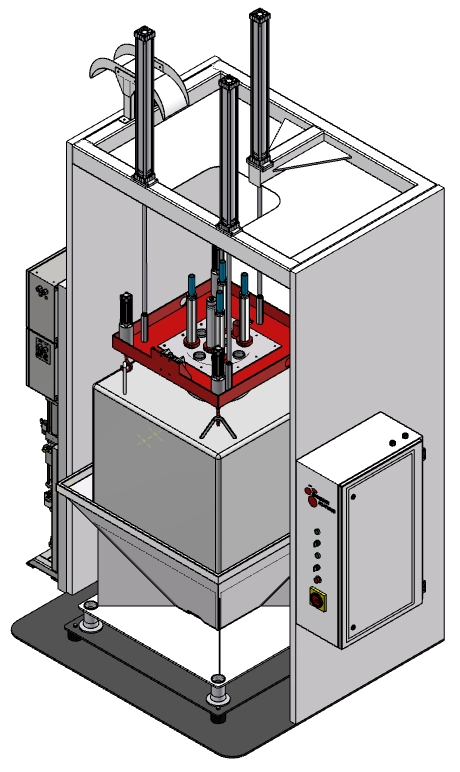

Automatic powder sieves incorporate motors, vibratory mechanisms, and sometimes air flows to continuously and uniformly process powder through screens without manual intervention. Powders are typically fed into the machine hopper, and the equipment performs shaking, vibrating, or rotating actions to segregate powders by size. Settings such as vibration frequency, duration, and feed rate can be preset and controlled electronically. The automatic process can handle large volumes efficiently with minimal labor input.

Efficiency and Throughput: Speed Differences

One of the most significant distinctions lies in processing speed and volume handling. Manual sieving is slower due to the physical effort required and limited batch sizes manageable by an operator. Screening large batches manually can be time-consuming and exhausting, stretching production timelines and risking inconsistency.

Conversely, automatic powder sieves achieve much higher throughput. Their continuous operation and optimized mechanical actions enable them to screen large quantities swiftly and without fatigue. For high-volume production lines, automatic models facilitate meeting tight deadlines and scaling operations effectively.

Accuracy and Consistency in Sieving

Manual Sieving: Risks of Human Error

Manual sieving accuracy can vary. Inconsistent powder distribution on the screen and variable shaking intensity lead to uneven particle separation. Human fatigue and imprecision may cause some larger particles to pass through or fine particles to remain trapped, affecting product uniformity and quality.

Automatic Sieving: Precision and Reproducibility

Automatic sieves ensure consistent, calibrated forces act on the powder, delivering uniform distribution and precise size segregation. Equipped with sensors and feedback controls, these machines monitor and adjust operations in real-time to maintain screening quality. This results in reproducible product batches essential for stringent industrial standards, especially in pharmaceutical and high-tech manufacturing.

Labor and Cost Considerations

Labor Intensity of Manual Methods

Manual sieving demands continuous operator presence, increasing labor costs and limiting scalability. Skilled operators are needed to maintain efficiency and quality, with work intensity rising at high volumes.

Reduced Labor Costs with Automation

Automatic sieving drastically cuts manual labor requirements. Operators mainly oversee machine operation and conduct routine maintenance, reducing the workforce needed. Although upfront equipment costs are higher, long-term savings in staffing and increased productivity often justify the investment.

Maintenance and Durability

Maintenance of Manual Sieves

Manual powder sieves are mechanically simple with fewer moving parts, making them easier and cheaper to maintain. Cleaning screens and replacing worn mesh suffice for upkeep.

Maintenance Challenges of Automatic Machines

Automatic sieves feature motors, conveyors, and complex components requiring regular inspection and servicing. Part replacements and technical troubleshooting may increase operational complexity. However, most suppliers provide maintenance manuals and support to streamline these tasks.

Cost of Equipment: Initial Investment vs Long-Term Value

Manual sieves are more affordable initially, suiting small-scale or budget-limited operations. Automatic sieves involve greater capital outlay due to advanced technology and construction. Yet, the efficiency, labor savings, accuracy, and output gains often deliver better returns over time for large-scale producers.

Operational Scenarios: Which Model Fits Your Needs?

- Small-Scale, Low-Volume Production: Manual sieves are adequate and cost-effective.

- High-Volume, High-Precision Manufacturing: Automatic sieves are preferable for speed and consistency.

- Budget Constraints: Manual sieves minimize upfront costs.

- Labor Availability: Automatic systems reduce dependency on skilled operators.

- Maintenance Capacity: Manual systems demand less technical maintenance but more operator attention.

Advantages and Disadvantages Summary

| Feature | Manual Sieving | Automatic Sieving |

| Initial Cost | Low | High |

| Throughput | Low | High |

| Labor Requirement | High | Low |

| Accuracy | Moderate (subject to human error) | High (consistent and controlled) |

| Maintenance | Simple and cheap | Complex, requires technical servicing |

| Scalability | Limited | Excellent |

Emerging Trends in Automatic Powder Sieving Technology

Recent innovations focus on improving the efficiency of automatic sieves through advanced vibratory designs, dual airflow systems to prevent clogging, and integration with automated feeding and packaging lines. These enhance machine lifespan, reduce downtime, and enable industrial-scale production of ultra-fine powders with minimal operator input.

Frequently Asked Questions (FAQs)

1. Can manual powder sieving produce results comparable to automatic sieving?

Manual sieving can achieve acceptable results for small batch sizes but often lacks the speed, consistency, and accuracy of automatic sieving, especially for large-scale applications.

2. What factors influence the choice between manual and automatic powder sieving?

Key factors include production volume, budget, desired accuracy, labor availability, and maintenance capacity.

3. How does automatic sieving reduce labor costs?

By automating the screening process, fewer operators are needed to monitor and maintain machinery, freeing labor for other tasks and reducing staffing costs.

4. Are maintenance costs higher for automatic sieves?

Yes, automatic sieves generally require more frequent and technical maintenance than manual sieves due to their mechanical complexity.

5. Is the initial investment in automatic sieving equipment justified?

For high-volume production where efficiency, accuracy, and labor saving are critical, the higher upfront cost is offset by increased productivity and product quality.

[1] https://www.vibratingscreensieve.com/blog/what-are-the-differences-between-manual-and-automatic-powder-screening-equipment-54944.html

[2] https://patents.google.com/patent/CN101678402A/zh

[3] https://www.allpackchina.com/powder-sieving-machine/

[4] https://patents.google.com/patent/WO2013078757A1/zh

[5] https://www.powdergun.com/power.htm

[6] https://patents.google.com/patent/WO2020216351A1/zh

[7] https://www.ramseierkoatings.com/news/Why-Choose-Powder-Sieve-Over-Manual-Methods.html

[8] https://patents.google.com/patent/CN107470140A/zh

[9] https://www.reddit.com/r/reloading/comments/yjo959/hand_measuring_every_powder_charge_vs_dispenser/

[10] https://patents.google.com/patent/CN118268248A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.