Content Menu

● Understanding Electrostatic Spray Technology

>> What Is Electrostatic Spraying?

>> How Do Electrostatic Spray Guns Work?

● Advantages of Using Electrostatic Spray Guns for Complex Geometries

>> Improved Coverage for Difficult Shapes

>> Reduced Overspray and Waste

>> Enhanced Transfer Efficiency

>> Faster Production Times

● Challenges and Considerations When Spraying Complex Geometries

>> Grounding the Workpiece Properly

>> Paint Type and Conductivity

>> Equipment Calibration and Maintenance

>> Operator Skill and Training

● Types of Electrostatic Spray Guns Suitable for Complex Geometries

>> Conventional Electrostatic Guns

>> High Volume Low Pressure (HVLP) Electrostatic Guns

>> Airless Electrostatic Spray Guns

● Techniques for Optimizing Electrostatic Spraying on Complex Shapes

>> Positioning and Movement

>> Multi-Axis Robots and Automation

>> Masking and Shielding

● Safety and Environmental Considerations

>> Static Electricity and Fire Risk

>> VOC Emissions and Solvent Use

● Maintenance Tips for Electrostatic Spray Guns

● Summary

● Frequently Asked Questions (FAQs)

Electrostatic spray guns have revolutionized the coating and finishing industry, especially when it comes to painting or coating objects with complex shapes and geometries. Mastering the use of these specialized tools can significantly improve finish quality, boost efficiency, and reduce waste. This detailed article explores everything you need to know about electrostatic spray guns designed for complex geometries, including how they work, their advantages, challenges, and practical considerations.

Understanding Electrostatic Spray Technology

What Is Electrostatic Spraying?

Electrostatic spraying is a method of applying paint or coating in which electrically charged particles are sprayed onto a workpiece that is grounded. The charged particles are attracted to the surface, enabling more efficient and even coating application. Unlike conventional spraying, this technology helps reduce overspray and paint waste, offering improved coverage especially for intricate or hard-to-reach areas.

How Do Electrostatic Spray Guns Work?

Electrostatic spray guns charge the coating material as it exits the gun's nozzle. This charging can be achieved through various methods:

- Direct charging: The paint is electrically charged as it passes through or near an electrode.

- Indirect charging: The particles become charged after atomization.

The positively charged particles are naturally attracted to the grounded negative or neutral workpiece, allowing coatings to “wrap around” curves, edges, and recesses of complex geometries more effectively.

Advantages of Using Electrostatic Spray Guns for Complex Geometries

Improved Coverage for Difficult Shapes

One major benefit of electrostatic spraying for complex parts is the wraparound effect caused by electrostatic attraction. This enables coatings to reach behind corners and into recesses that are typically missed by conventional spray methods.

Reduced Overspray and Waste

Since particles are drawn directly to the target surface, overspray is minimized. This reduces paint usage, lowers costs, and results in less environmental pollution. For manufacturers concerned with sustainability and regulatory compliance, this is a major advantage.

Enhanced Transfer Efficiency

Transfer efficiency is the proportion of the paint material that actually adheres to the workpiece versus what is lost to the air or overspray. Electrostatic spray guns offer significantly higher transfer efficiency compared to air spray or airless spray guns, sometimes achieving transfer rates of over 80%.

Faster Production Times

Because the coatings apply more effectively and evenly, manufacturers can achieve full coverage in fewer passes, speeding up the production process without compromising quality.

Challenges and Considerations When Spraying Complex Geometries

Grounding the Workpiece Properly

For the electrostatic effect to work, the workpiece must be grounded correctly. Poor grounding can lead to uneven coatings, paint buildup, or even safety hazards such as static discharge sparks, which could ignite flammable paint materials.

Paint Type and Conductivity

Not all coatings are suitable for electrostatic application. Water-based paints are often more challenging to charge adequately due to their lower conductivity. Specialized formulations optimized for electrostatic use may be required for complex shapes to ensure consistent charging and adhesion.

Equipment Calibration and Maintenance

Precision is crucial when spraying complex parts. Electrostatic spray guns require regular calibration to maintain optimal voltage levels and spray patterns. Components such as electrodes, nozzles, and cables must be inspected and cleaned regularly to avoid malfunctions that can cause inconsistent coatings or equipment damage.

Operator Skill and Training

The effectiveness of electrostatic spraying for complex geometries depends heavily on operator expertise. Factors such as gun distance, angle, speed, and voltage settings need correct adjustment for different part sizes and shapes.

Types of Electrostatic Spray Guns Suitable for Complex Geometries

Conventional Electrostatic Guns

These guns deliver a charged paint spray using compressed air to atomize the coating. They are versatile and commonly used, but the compressed air spray can create more overspray compared to newer technologies.

High Volume Low Pressure (HVLP) Electrostatic Guns

HVLP electrostatic guns use lower air pressure to atomize the coating, reducing overspray and improving transfer efficiency. This type is particularly well-suited for detailed work and complex shapes where precision is critical.

Airless Electrostatic Spray Guns

Airless guns do not use compressed air; instead, high-pressure pumps force the paint through a tiny orifice. This creates a fine spray pattern. When combined with electrostatic charging, these guns offer deep coating penetration on complex shapes with very little overspray.

Techniques for Optimizing Electrostatic Spraying on Complex Shapes

Positioning and Movement

Moving the electrostatic spray gun steadily and at consistent distances (typically around 6 to 12 inches from the surface) helps maintain an even charge distribution and coating thickness. For geometries with deep recesses, orienting the gun at different angles allows the charged particles to wrap around edges evenly.

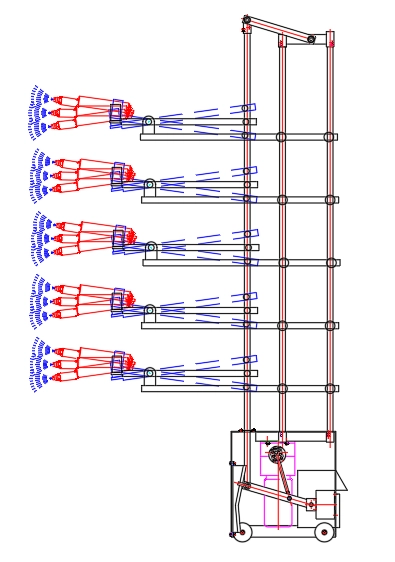

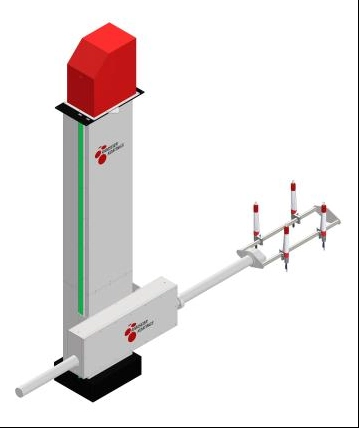

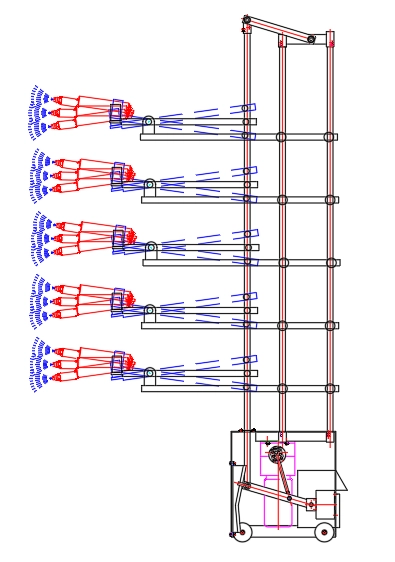

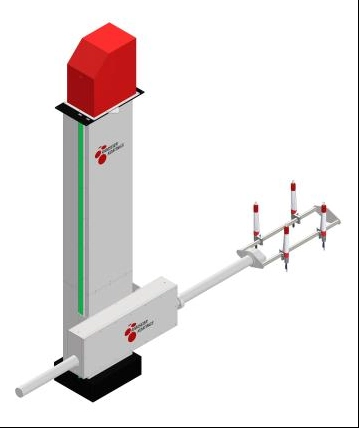

Multi-Axis Robots and Automation

For industrial applications, integrating electrostatic spray guns with robotic arms helps automate complex spray paths. Robots can programmatically adjust angles and distances for intricate shapes, ensuring consistent finish quality and reducing human error.

Masking and Shielding

Although electrostatic spraying minimizes overspray, masking areas not to be coated is essential for some complex geometries, especially those with mixed materials or functional surfaces that must remain paint-free.

Safety and Environmental Considerations

Static Electricity and Fire Risk

The generation of static electricity means that electrostatic spraying must be executed with strict safety protocols. Proper grounding, ventilation, and explosion-proof equipment reduce the risk of sparks and fire during spraying operations.

VOC Emissions and Solvent Use

Electrostatic spraying can reduce the volume of volatile organic compounds (VOC) released by lowering paint waste. However, the specific paint formulation and spraying environment should comply with environmental regulations to maintain workplace safety and minimize ecological impact.

Maintenance Tips for Electrostatic Spray Guns

- Regularly clean the spray nozzle and electrode to prevent paint buildup.

- Inspect and replace damaged cables or wiring to ensure safe operation.

- Check voltage output settings frequently to maintain optimal charging.

- Calibrate spray patterns and flow rates according to manufacturer instructions.

- Store equipment in a dry, dust-free environment to prolong lifespan.

Summary

Electrostatic spray guns provide a highly efficient and effective method to coat complex geometries with superior coverage and reduced waste. By understanding the principles of electrostatic charging, selecting the right equipment, and applying proper techniques, manufacturers can achieve outstanding finish quality on even the most challenging shapes. Operator training, grounding, paint compatibility, and safety measures are crucial for successful outcomes. As industries demand higher precision and sustainability, electrostatic spray technology remains a key innovation in advanced coating processes.

Frequently Asked Questions (FAQs)

1. Can electrostatic spray guns be used with all types of paint?

Not all paints are equally suitable; water-based and low-conductivity coatings may require specialized formulations to charge properly. Consult with paint manufacturers for compatibility.

2. What is the ideal distance to hold the spray gun from complex surfaces?

Typically, a distance between 6 and 12 inches (15 to 30 cm) works best, but this varies depending on the gun type and paint viscosity.

3. How do I ensure proper grounding of irregularly shaped parts?

Use conductive clamps or grounding straps attached securely to the part or fixture. All conductive surfaces in contact with the part should maintain electrical continuity to the ground.

4. What maintenance is most critical for electrostatic spray guns?

Cleaning electrodes and nozzles regularly is crucial, along with inspecting cables for wear and verifying voltage output levels.

5. How does automation improve electrostatic coating on complex geometries?

Robotic systems can consistently reproduce precise spray paths and angles, reducing human error and improving coating consistency on irregular surfaces.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.