Content Menu

● Introduction

● Understanding Particle Size

>> What is Particle Size?

>> Importance of Particle Size

● The Role of Sieve Analysis

>> What is Sieve Analysis?

>> Methods of Sieve Analysis

● Factors Influencing Particle Size Control

>> Material Properties

>> Processing Conditions

>> Equipment Selection

● Applications of Particle Size Control

>> Pharmaceuticals

>> Food Industry

>> Chemical Manufacturing

>> Construction Materials

● Challenges in Particle Size Control

>> Variability in Raw Materials

>> Equipment Limitations

>> Environmental Factors

● Best Practices for Particle Size Control

>> Regular Monitoring

>> Process Optimization

>> Training and Education

● Conclusion

● Frequently Asked Questions

>> 1. Why is particle size important in pharmaceuticals?

>> 2. What methods are used for particle size analysis?

>> 3. How does particle size affect food products?

>> 4. What challenges are associated with particle size control?

>> 5. How can manufacturers optimize particle size control?

Introduction

In the world of manufacturing and processing, the size of particles plays a crucial role in determining the quality and performance of products. From pharmaceuticals to food production, the control of powder sieve particle size is essential for ensuring consistency, efficiency, and safety. This article delves into the significance of particle size control, the methods used to achieve it, and the implications it has across various industries.

Understanding Particle Size

What is Particle Size?

Particle size refers to the dimensions of individual particles in a powder. It is typically measured in micrometers (µm) or nanometers (nm) and can significantly influence the behavior of materials during processing and their final properties. The distribution of particle sizes within a powder is known as particle size distribution (PSD), which is critical for understanding how a powder will perform in various applications.

Importance of Particle Size

The size of particles affects several key properties, including:

- Flowability: Smaller particles tend to have poorer flow characteristics due to increased surface area and inter-particle friction.

- Dissolution Rate: In pharmaceuticals, smaller particles dissolve faster, leading to quicker absorption in the body.

- Reactivity: The surface area of particles can influence their reactivity, which is particularly important in chemical processes.

- Packing Density: Particle size affects how tightly particles can pack together, impacting the volume and weight of the final product.

The Role of Sieve Analysis

What is Sieve Analysis?

Sieve analysis is a technique used to determine the particle size distribution of a powder. It involves passing the powder through a series of sieves with different mesh sizes. The amount of powder retained on each sieve is measured, allowing for the calculation of the PSD.

Methods of Sieve Analysis

There are several methods for conducting sieve analysis, including:

- Dry Sieve Analysis: This method is commonly used for powders that do not clump together. The powder is placed on the top sieve, and mechanical shaking separates the particles based on size.

- Wet Sieve Analysis: For powders that tend to agglomerate, wet sieve analysis is used. Water or another liquid is added to the powder, which helps to break up clumps and allows for more accurate sizing.

- Laser Diffraction: This modern technique uses laser light to measure the size of particles as they scatter light. It is particularly useful for very fine powders.

Factors Influencing Particle Size Control

Material Properties

The inherent properties of the material being processed can significantly affect particle size. For example, brittle materials tend to break into smaller particles, while ductile materials may deform rather than fracture. Understanding these properties is essential for selecting the appropriate processing methods.

Processing Conditions

The conditions under which a powder is processed can also influence particle size. Factors such as temperature, pressure, and the presence of additives can alter the size and distribution of particles. For instance, high temperatures may cause thermal degradation, leading to changes in particle size.

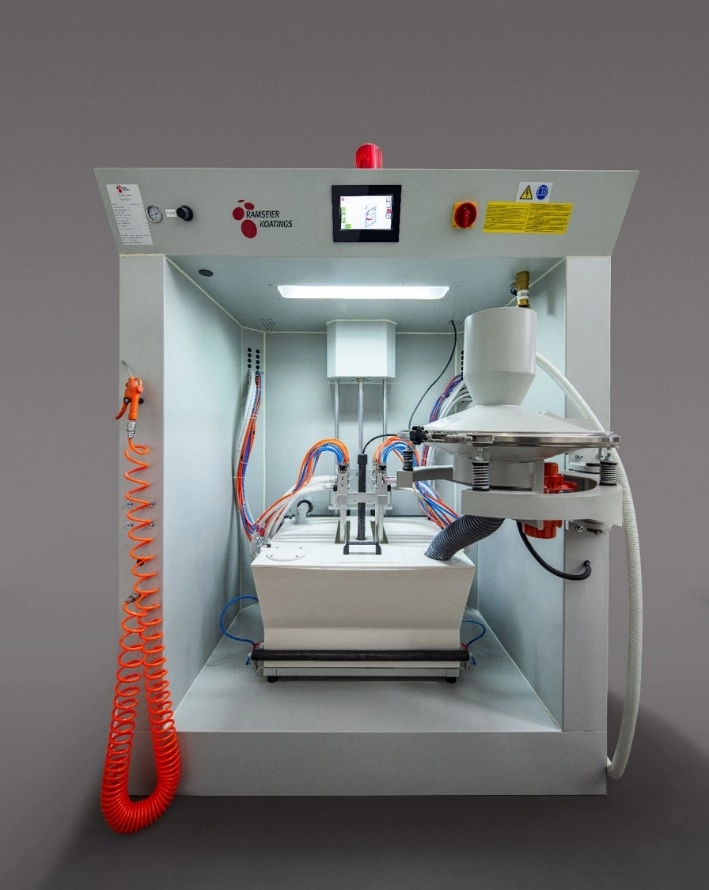

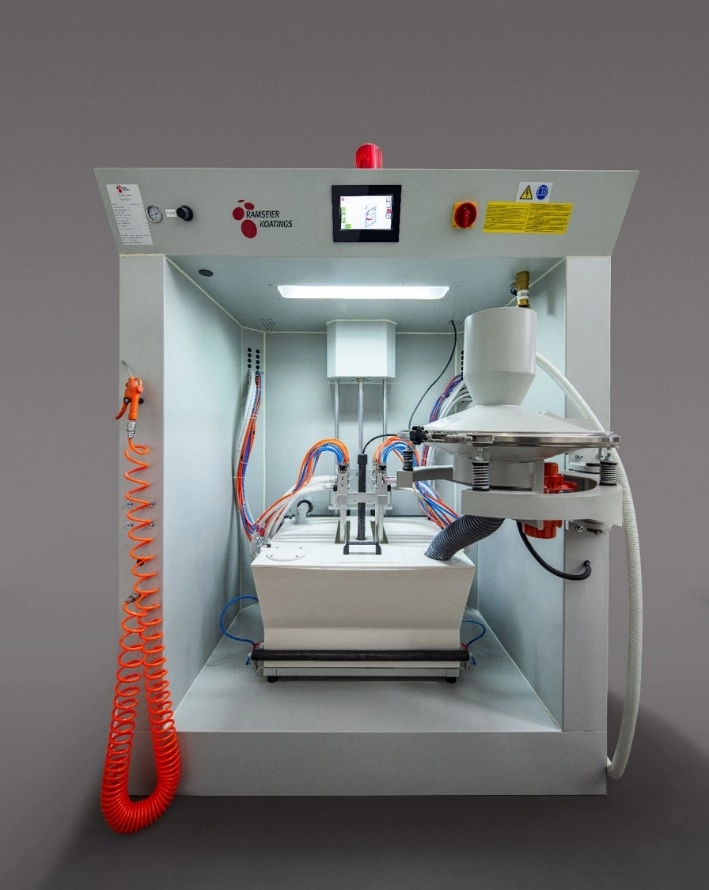

Equipment Selection

The choice of equipment used for size reduction and classification is critical. Different mills and classifiers are designed for specific particle size ranges and material types. Selecting the right equipment can enhance efficiency and ensure consistent particle size control.

Applications of Particle Size Control

Pharmaceuticals

In the pharmaceutical industry, particle size control is vital for ensuring the efficacy and safety of medications. Smaller particles can enhance bioavailability, leading to faster therapeutic effects. Additionally, consistent particle size helps in achieving uniformity in dosage forms, such as tablets and capsules.

Food Industry

Particle size control in the food industry affects texture, flavor release, and shelf life. For example, in the production of powdered spices, a consistent particle size ensures uniform flavor distribution in food products. Similarly, in dairy processing, controlling the size of milk powder particles can influence solubility and rehydration properties.

Chemical Manufacturing

In chemical manufacturing, particle size can impact reaction rates and product quality. For instance, catalysts often require specific particle sizes to maximize surface area and enhance reaction efficiency. Controlling particle size in this context is crucial for optimizing production processes and ensuring product consistency.

Construction Materials

In the construction industry, the particle size of materials like cement and aggregates affects the strength and durability of concrete. Properly controlled particle sizes can lead to improved workability and reduced water demand, ultimately enhancing the performance of construction materials.

Challenges in Particle Size Control

Variability in Raw Materials

One of the primary challenges in particle size control is the variability in raw materials. Natural materials often exhibit a wide range of particle sizes, which can complicate processing. Implementing effective quality control measures is essential to mitigate this variability.

Equipment Limitations

While modern equipment offers advanced capabilities for particle size control, limitations still exist. For example, some mills may not achieve the desired particle size for certain materials, necessitating the use of multiple processing steps. Understanding the limitations of equipment is crucial for optimizing particle size control strategies.

Environmental Factors

Environmental factors, such as humidity and temperature, can also influence particle size. For instance, moisture can cause powders to clump together, leading to larger particle sizes. Implementing proper storage and handling procedures is essential to minimize these effects.

Best Practices for Particle Size Control

Regular Monitoring

Regular monitoring of particle size is essential for maintaining quality control. Implementing a robust quality assurance program that includes routine sieve analysis can help identify variations in particle size and allow for timely adjustments in processing.

Process Optimization

Optimizing processing conditions can significantly enhance particle size control. This may involve adjusting parameters such as milling speed, feed rate, and temperature to achieve the desired particle size distribution.

Training and Education

Investing in training and education for personnel involved in powder processing can lead to better understanding and implementation of particle size control measures. Knowledgeable staff can make informed decisions that enhance product quality and consistency.

Conclusion

In conclusion, powder sieve particle size control is a critical aspect of various industries, impacting product quality, efficiency, and safety. Understanding the importance of particle size, the methods for controlling it, and the challenges involved can help manufacturers optimize their processes and deliver high-quality products. As industries continue to evolve, the significance of particle size control will only grow, making it an essential focus for future advancements.

Frequently Asked Questions

1. Why is particle size important in pharmaceuticals?

Particle size affects the dissolution rate and bioavailability of drugs, influencing how quickly and effectively they work in the body.

2. What methods are used for particle size analysis?

Common methods include dry sieve analysis, wet sieve analysis, and laser diffraction.

3. How does particle size affect food products?

Particle size influences texture, flavor release, and solubility, impacting the overall quality of food products.

4. What challenges are associated with particle size control?

Challenges include variability in raw materials, equipment limitations, and environmental factors such as humidity.

5. How can manufacturers optimize particle size control?

Regular monitoring, process optimization, and staff training are key strategies for enhancing particle size control.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.